Control arm assembly bench test system for Mcpherson suspension of passenger vehicle

A bench test and control arm technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as high cost, difficult bench failure form, and long cycle, so as to shorten the development cycle , rapid quality improvement plan, and verify the effect of the quality improvement plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

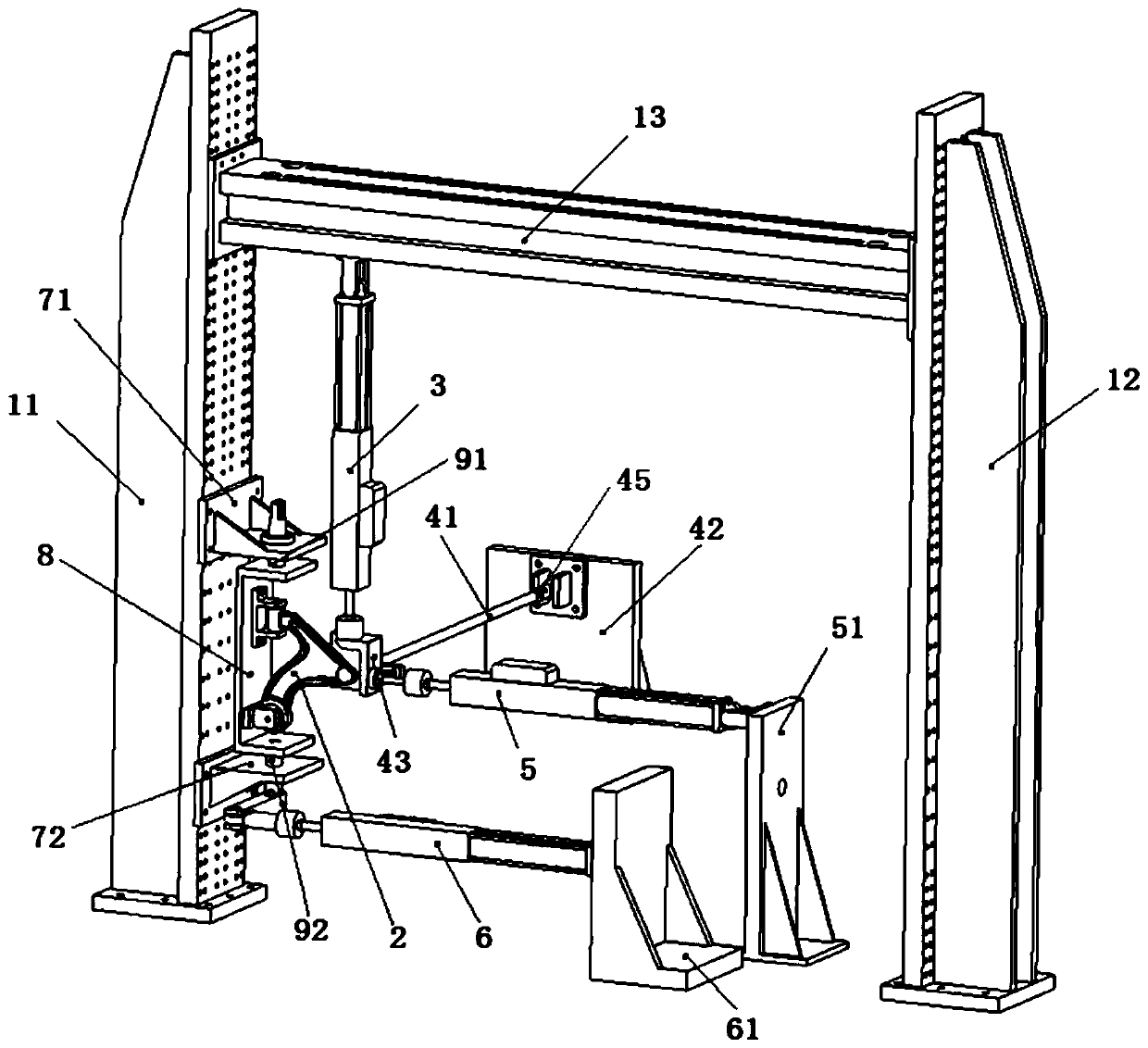

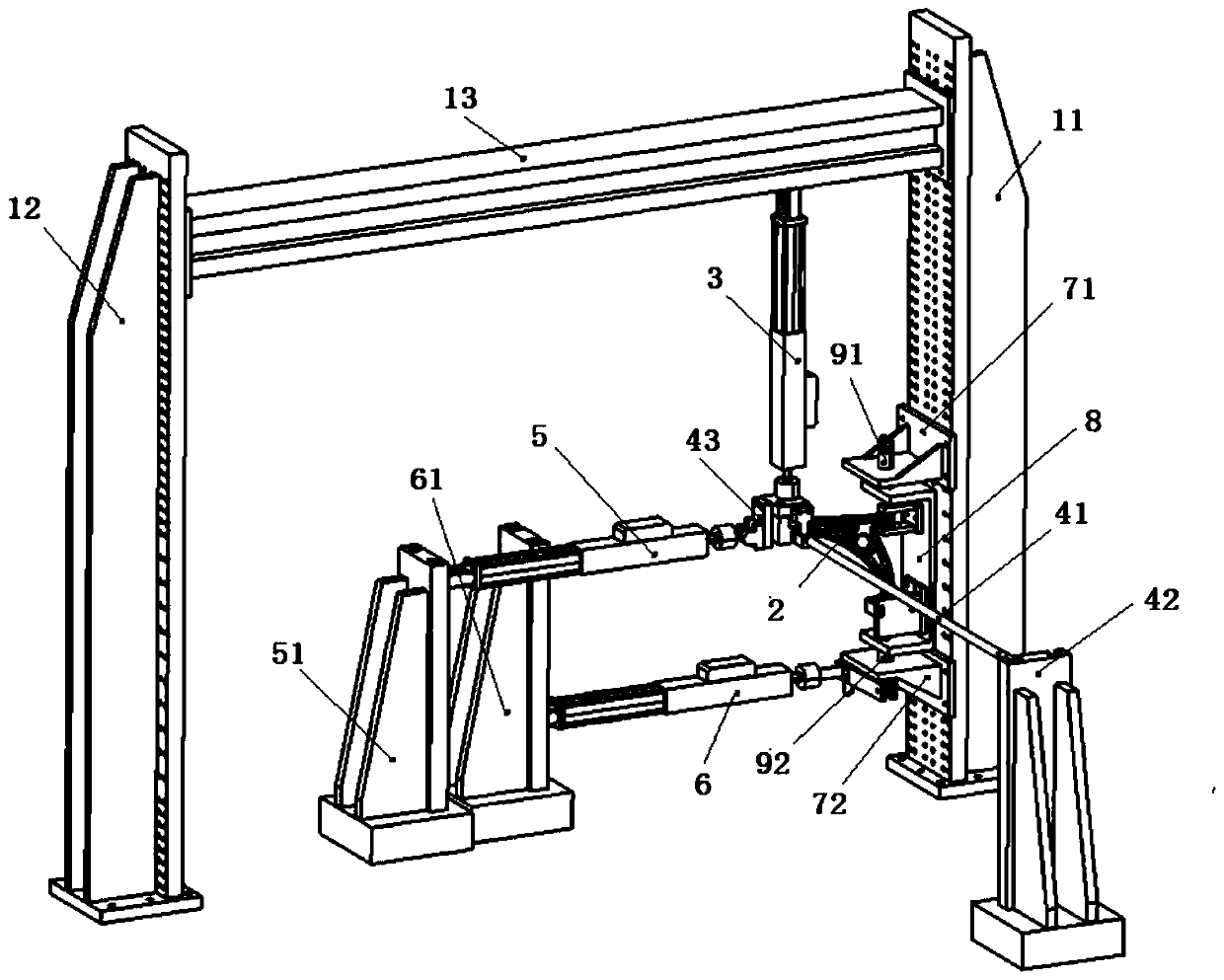

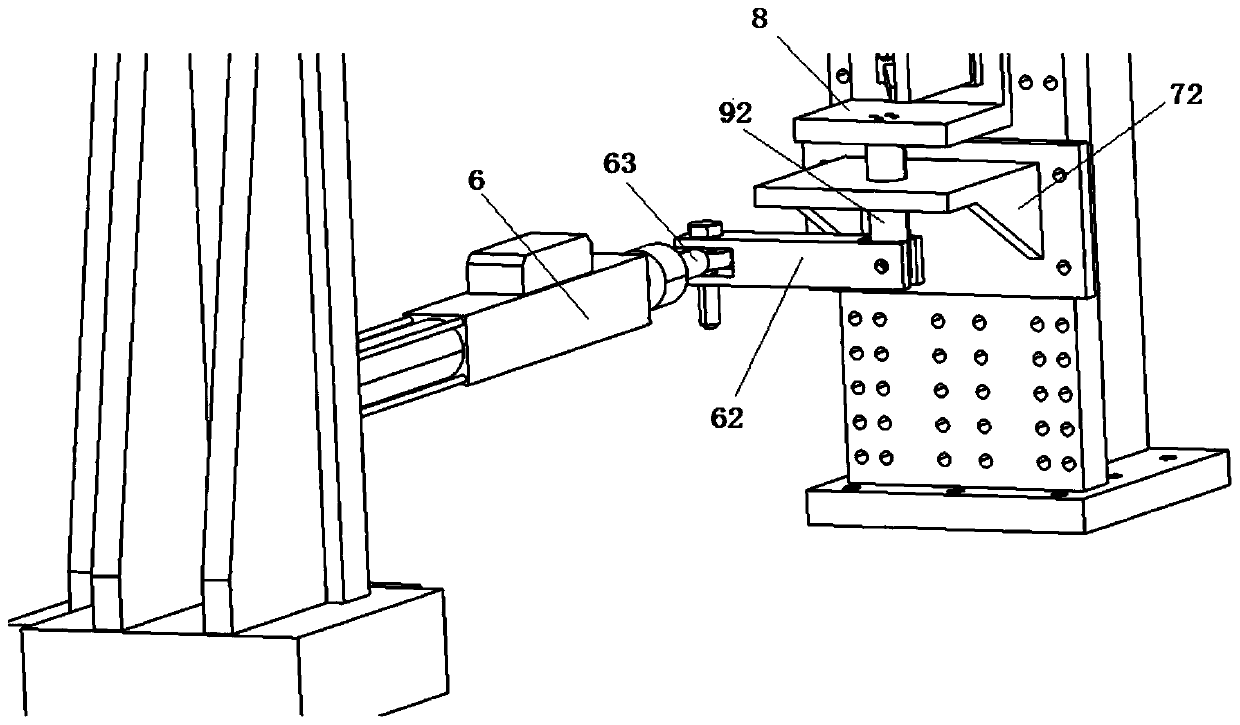

[0020] Such as figure 1 , 2 As shown, the control arm assembly bench test system for passenger car McPherson suspension of the present invention comprises a bench, a first linear actuator 3, a guide rod 41, a guide seat 42, a loading seat 43, a second A linear actuator 5, a third linear actuator 6, an upper base 71, a lower base 72, and a torsion seat 8.

[0021] Described stand comprises left frame 11, right frame 12 and crossbeam 13; The two ends of crossbeam 13 are fixedly connected with left frame 11, right frame 12 respectively; Upper base 71 and lower base 72 are fixed on the left frame 11 by bolts; The upper end of the torsion seat 8 is connected to the upper torsion shaft 91 by bolts, and the upper torsion shaft 91 is connected to the upper base 71 through a tapered roller bearing; the lower end of the torsion seat 8 is connected to the lower torsion shaft 92 by bolts, and the lower torsion shaft 92 is connected by a tapered roller bearing Connected with the lower ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com