Method for safely reusing and treating hydrogenated tail gas in hydrogenation reaction device

A technology of hydrogenation reaction and treatment method, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as poor safety, and achieve the effect of preventing explosion, ensuring overall safety, and achieving good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

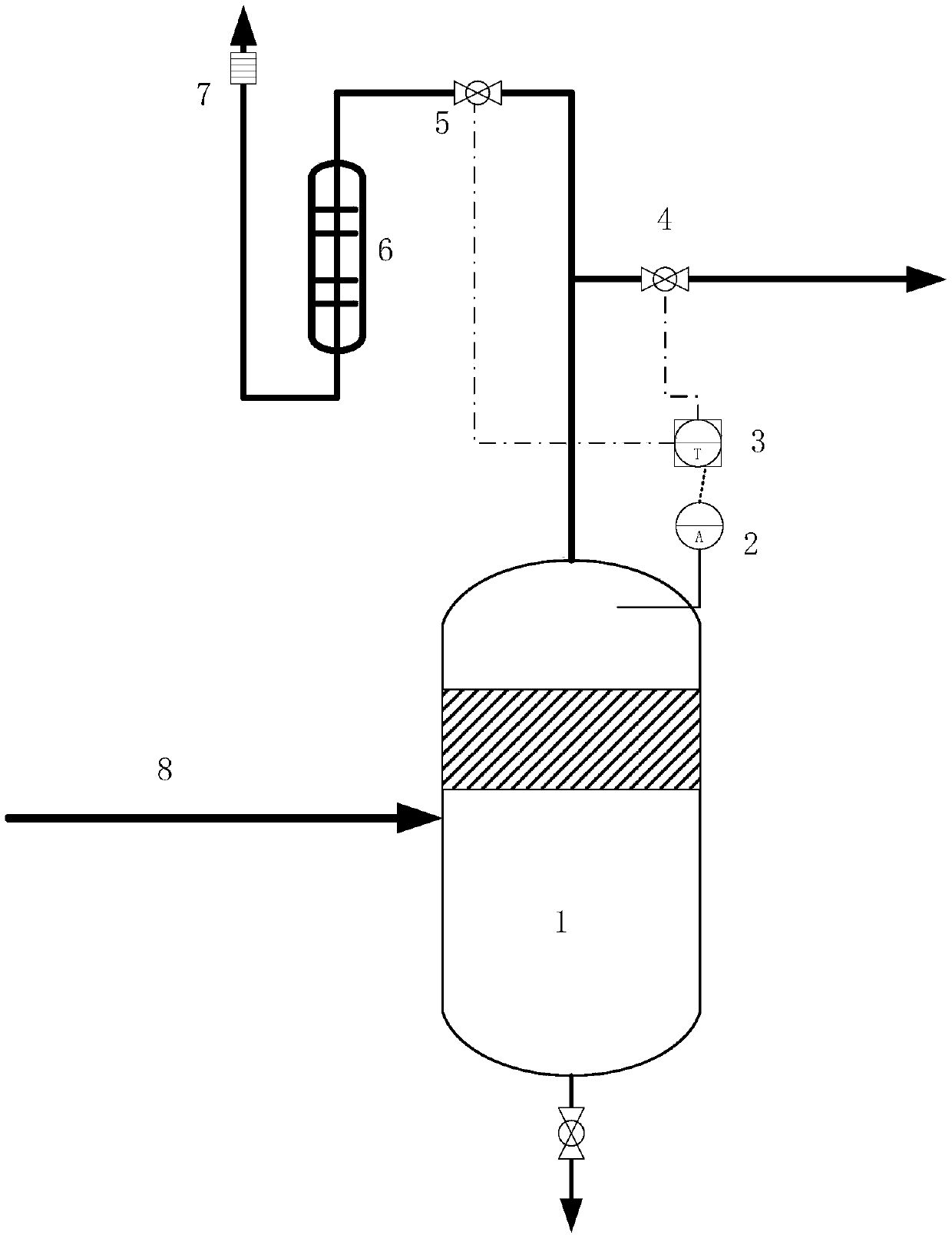

[0018] A method for safe reuse and treatment of hydrogenation tail gas in a hydrogenation reaction device, such as figure 1 As shown, after the purge gas of the aromatics hydrogenation system is separated by the gas-liquid separator, part of the gas phase enters the low-temperature catalytic oxidation reactor through the discharge pipeline, the gas at the outlet of the reactor is discharged after passing through the flame arrester, and the other part of the gas phase enters the hydrogen recovery pipeline; A gas component analyzer is installed at the gas phase outlet on the top of the liquid separator to analyze the composition changes in the tail gas online. When hydrogen reuse is selected, an upper limit index is set for the content of organic matter in the tail gas. When this index is exceeded, the reuse pipeline valve is automatically closed. , while opening the discharge pipeline valve; the low-temperature catalytic oxidation reactor is equipped with a catalyst and an adsor...

Embodiment 2

[0023] A method for safe reuse and treatment of hydrogenation tail gas in a hydrogenation reaction device, such as figure 1 As shown, after the purge gas of the aromatics hydrogenation system is separated by the gas-liquid separator, part of the gas phase enters the low-temperature catalytic oxidation reactor through the discharge pipeline, the gas at the outlet of the reactor is discharged after passing through the flame arrester, and the other part of the gas phase enters the hydrogen recovery pipeline; A gas component analyzer is installed at the gas phase outlet on the top of the liquid separator to analyze the composition changes in the tail gas online. When hydrogen reuse is selected, an upper limit index is set for the content of organic matter in the tail gas. When this index is exceeded, the reuse pipeline valve is automatically closed. , while opening the discharge pipeline valve; the low-temperature catalytic oxidation reactor is equipped with a catalyst and an adsor...

Embodiment 3

[0028] A method for safe reuse and treatment of hydrogenation tail gas in a hydrogenation reaction device, such as figure 1 As shown, after the purge gas of the aromatics hydrogenation system is separated by the gas-liquid separator, part of the gas phase enters the low-temperature catalytic oxidation reactor through the discharge pipeline, the gas at the outlet of the reactor is discharged after passing through the flame arrester, and the other part of the gas phase enters the hydrogen recovery pipeline; A gas component analyzer is installed at the gas phase outlet on the top of the liquid separator to analyze the composition changes in the tail gas online. When hydrogen reuse is selected, an upper limit index is set for the content of organic matter in the tail gas. When this index is exceeded, the reuse pipeline valve is automatically closed. , while opening the discharge pipeline valve; the low-temperature catalytic oxidation reactor is equipped with a catalyst and an adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com