Safe adsorption treatment device and method for hydrogen-containing purge gas

A technology of adsorption treatment and degassing, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as poor safety, and achieve the effects of preventing safety problems, good technical effects, safe and reliable control and operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

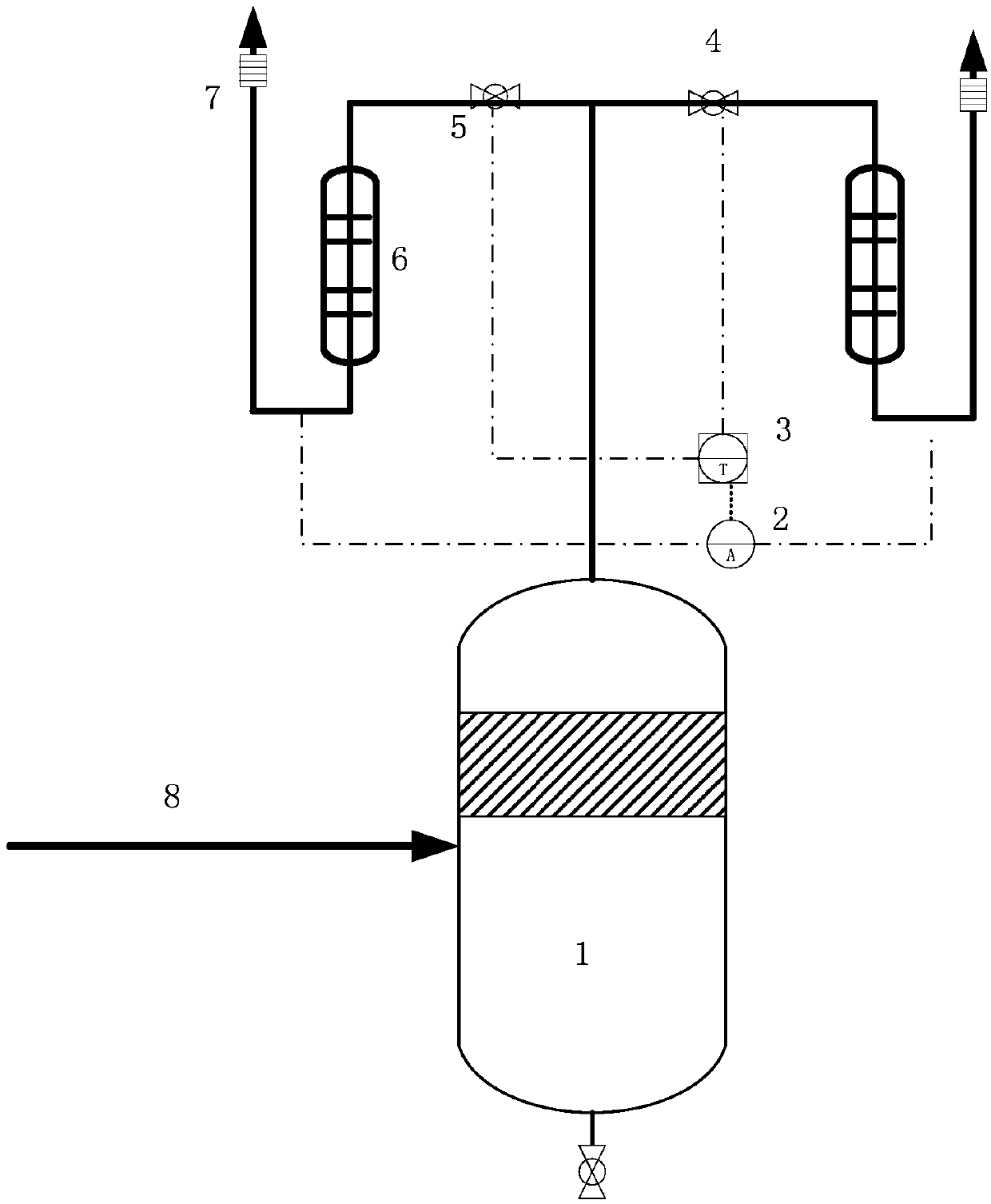

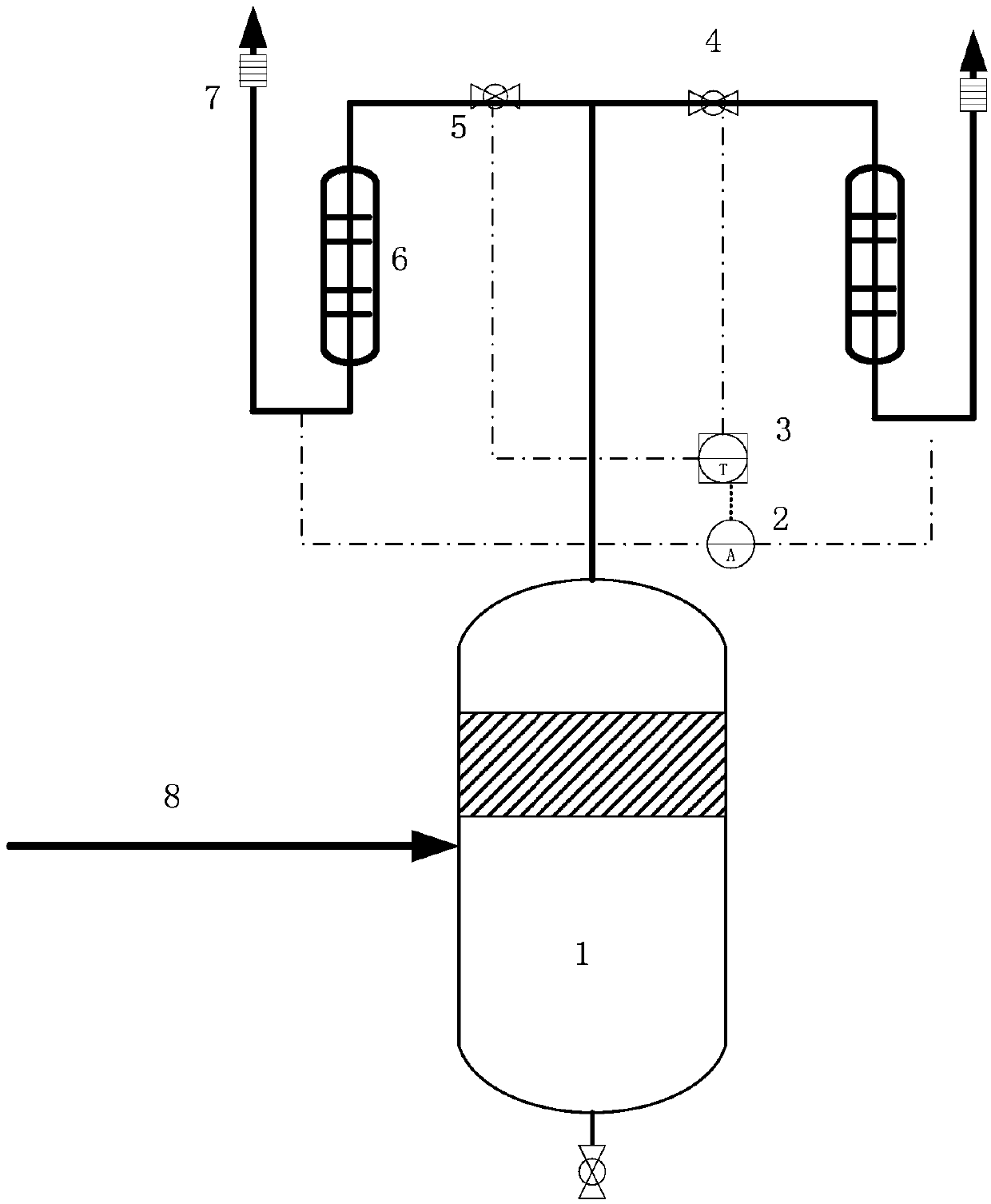

[0020] A safe adsorption treatment method for hydrogen-containing purge gas, such as figure 1 As shown, after the exhaust gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters at least two adsorption processors through the discharge pipeline. Finally, it indicates that the adsorption is saturated, then switch to another adsorber; the adsorption processor is filled with adsorbent, and the adsorbent is a magnesium alloy.

[0021] The adsorption processor adopts a combined structure, and is equipped with an inlet head, an air outlet head and an adsorption module. Both the head and the adsorption module are of flange flange structure, and the required number of adsorption modules can be installed according to the needs. A gas composition monitoring analyzer is installed on the top of the gas-liquid separator. A flame arrester is installed on the outlet pipeline of the adsorption processor. The operating conditions of the adsorpt...

Embodiment 2

[0024] A safe adsorption treatment method for hydrogen-containing purge gas, such as figure 1 As shown, after the exhaust gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters at least two adsorption processors through the discharge pipeline. Finally, it indicates that the adsorption is saturated, then switch to another adsorber; the adsorption processor is filled with adsorbent, and the adsorbent is nickel alloy.

[0025] The adsorption processor adopts a combined structure, and is equipped with an inlet head, an air outlet head and an adsorption module. Both the head and the adsorption module are of flange flange structure, and the required number of adsorption modules can be installed according to the needs. A gas composition monitoring analyzer is installed on the top of the gas-liquid separator. The operating conditions of the adsorption processor are temperature 20°C, pressure 0.2MPa, space velocity 500h -1 .

[0026]...

Embodiment 3

[0028] A safe adsorption treatment method for hydrogen-containing purge gas, such as figure 1 As shown, after the exhaust gas of the aromatics hydrogenation system is separated by the gas-liquid separator, the gas phase enters at least two adsorption processors through the discharge pipeline. Finally, it indicates that the adsorption is saturated, then switch to another adsorber; the adsorption processor is filled with adsorbent, and the adsorbent is titanium alloy.

[0029] The adsorption processor adopts a combined structure, and is equipped with an inlet head, an air outlet head and an adsorption module. Both the head and the adsorption module are of flange flange structure, and the required number of adsorption modules can be installed according to the needs. A gas composition monitoring analyzer is installed on the top of the gas-liquid separator. The operating conditions of the adsorption processor are temperature 40°C, pressure 0.5MPa, space velocity 600h -1 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com