Biaxial tilting quad-rotor aircraft

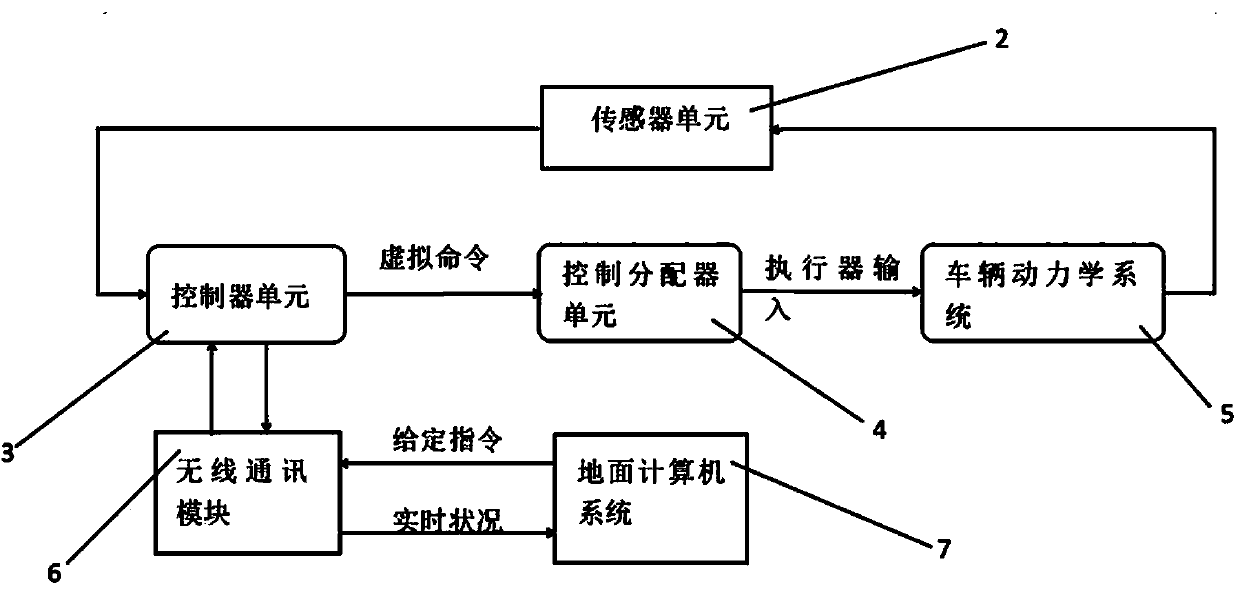

A quad-rotor aircraft, the technology of the aircraft, applied in the direction of aircraft, unmanned aircraft, rotorcraft, etc., can solve the problems of increased body weight, complex structure, low lift and weight of multi-rotor aircraft, and reduced scale and size , the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

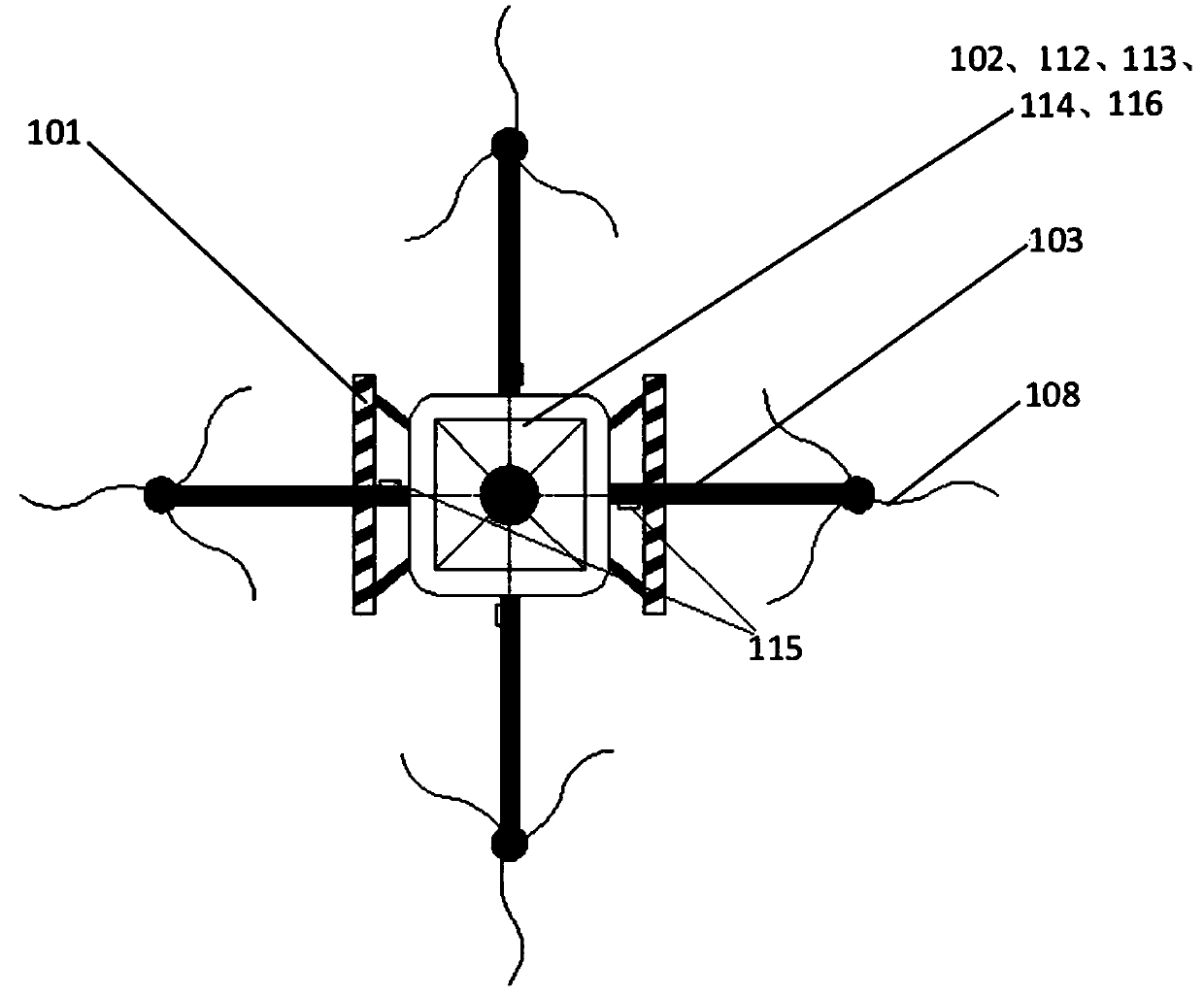

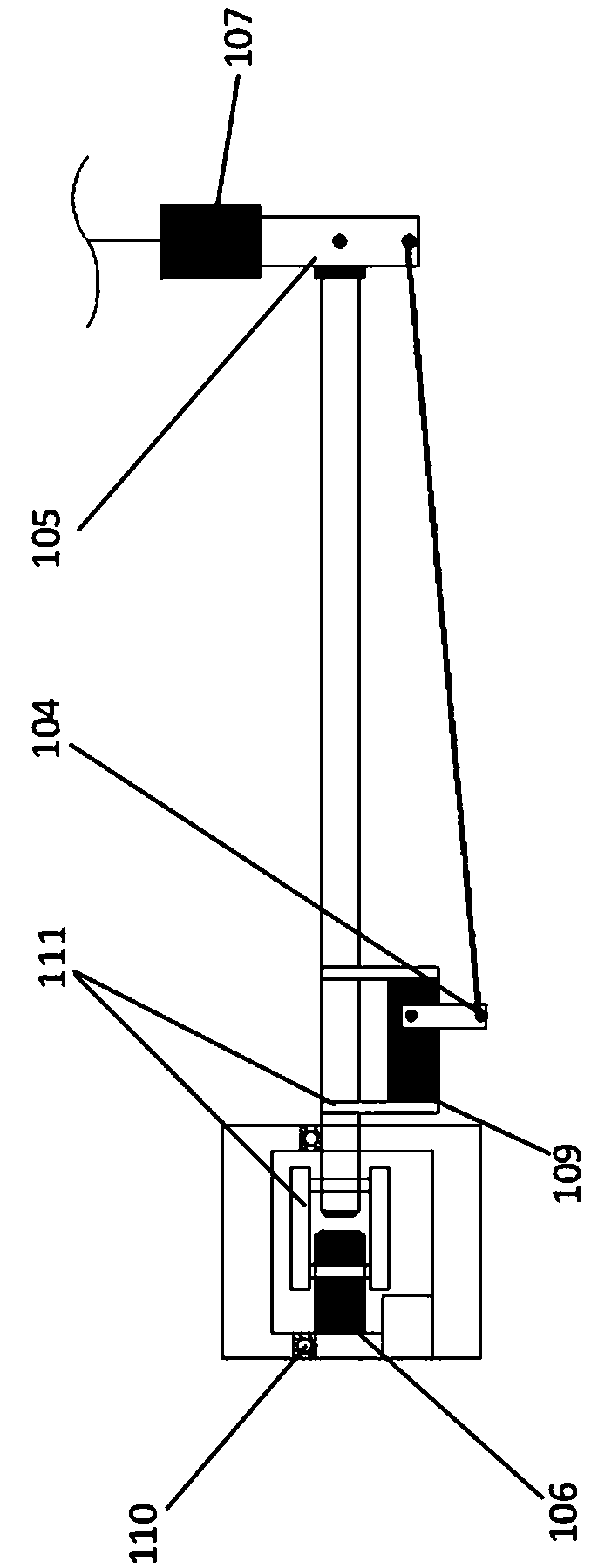

[0083] When the aircraft is changing its flight attitude, the controller unit controls the tilting mechanism, the servo motor drives the support arm to rotate so that the rotor tilts vertically in the direction perpendicular to the support arm, and the steering gear drives the motor holder to swing through the linkage mechanism to make the rotor rotate in the direction perpendicular to the support arm. The plane where the fuselage is located is tilted inward or outward, changing the lift output direction of the aircraft, and changing the flight attitude of the aircraft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com