Method for producing steel by using limestone in semisteel steelmaking of top-bottom combined blowing converter

A top-bottom re-blowing, limestone technology, applied in the field of metallurgy, can solve the problems of low heat, low carbon content, difficult slagging in converters, etc., and achieve the effects of reducing production costs, promoting the interface between steel and slag, and shortening the slag slag time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

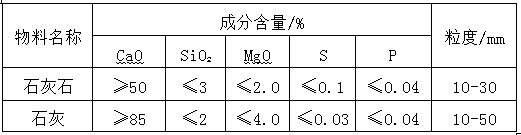

[0020] In this embodiment, a method of using limestone slag-making steelmaking in the semi-steelmaking of the top-bottom combined blowing converter is as follows:

[0021] After the converter receives the slag splash protection furnace, add semi-steel into the steelmaking converter, the temperature of the semi-steel is 1350 ℃, P: 0.08%, and then add limestone, lime, light-burned dolomite materials for slagging and oxygen blowing, The basicity of the slag is 2.5, and the oxygen supply blowing time is 12 minutes. The oxygen lance is blown at a lower position before and during the middle stage of the oxygen supply blowing, and at a higher position in the later period. During the oxygen supply blowing process of the converter, according to For smelting, 500kg of limestone is added in 3 batches with a particle size of 15mm, and a total of 1500kg of lime is added, that is, limestone:lime=1:3, and the end point of smelting is controlled: C: 0.06%, P: 0.008%, and the end point temperat...

Embodiment 2

[0024] In this embodiment, a method of using limestone slag-making steelmaking in the semi-steelmaking of the top-bottom combined blowing converter is as follows:

[0025] After receiving the slag-splashing protective furnace of the converter, add semi-steel into the steelmaking converter, the temperature of the semi-steel is 1420°C, P: 0.208%, and then add limestone, lime, and light-burned dolomite materials for slagging and oxygen blowing. The basicity of the slag is 3.5, and the oxygen supply blowing time is 10 minutes. The oxygen lance is blown at a lower position before and during the middle stage of the oxygen supply blowing, and at a higher position in the later period. During the oxygen supply blowing process of the converter, according to For smelting, 1000kg of limestone is added in 4 batches, the particle size is 20mm, and 1000kg of lime is added in total, that is, limestone:lime=1:1, and the smelting end point is controlled: C: 0.10%, P: 0.015%, and the end point te...

Embodiment 3

[0028] In this embodiment, a method of using limestone slag-making steelmaking in the semi-steelmaking of the top-bottom combined blowing converter is as follows:

[0029] After the converter receives the slag splash protection furnace, add semi-steel into the steelmaking converter, the temperature of the semi-steel is 1380 ℃, P: 0.103%, and then add limestone, lime, light-burned dolomite materials for slagging and oxygen blowing, The basicity of the slag is 4.0, and the oxygen supply blowing time is 15 minutes. The oxygen lance is blown at a lower position before and during the middle stage of the oxygen supply blowing, and at a higher position in the later period. For smelting, 800kg of limestone is added in 5 batches with a particle size of 30mm, and a total of 1600kg of lime is added, that is, limestone:lime=1:2, and the end point of smelting is controlled: C: 0.08%, P: 0.006%, and the end point temperature is 1665°C. Furnace out of steel.

[0030] By adopting the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com