Construction method of steel-concrete combined section of long-span cable-stayed bridge

A cable-stayed bridge steel and construction method technology, applied to cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as adverse effects of bridge service periods, difficulties in construction of steel-concrete joints, and difficulties in using construction machines and tools, and achieve improvement Stress of the structure, excellent pouring quality, and the effect of reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0033] Specific embodiments of the invention will be described in detail below.

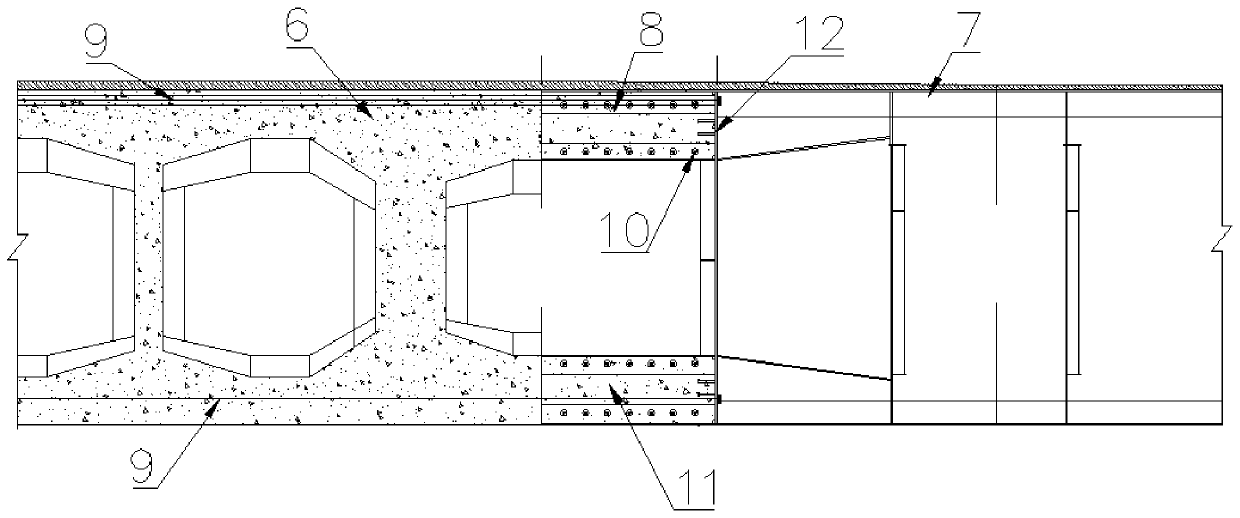

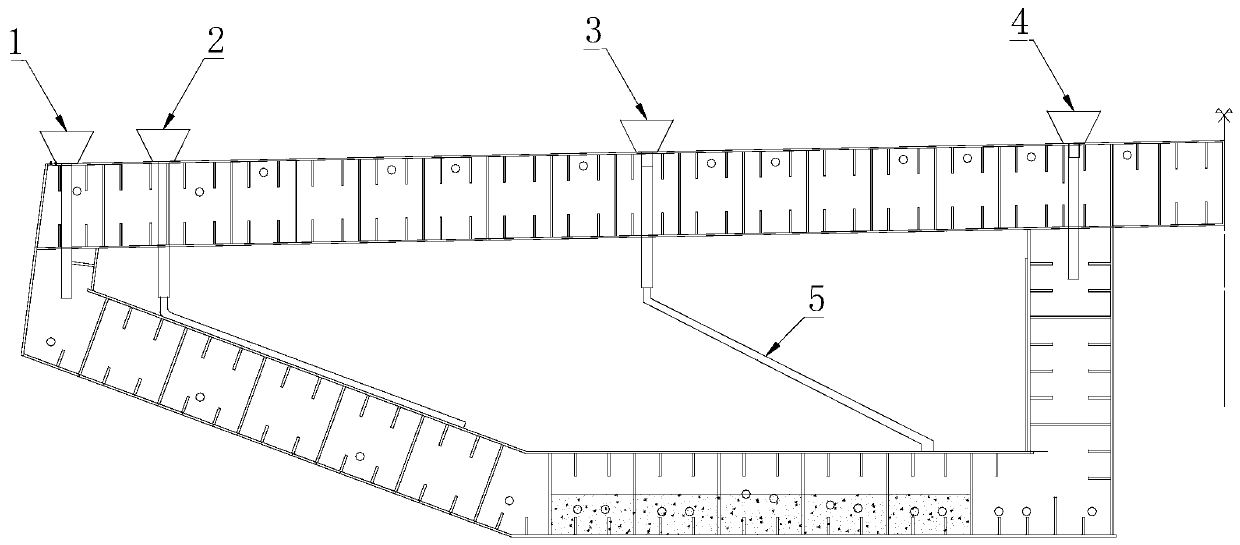

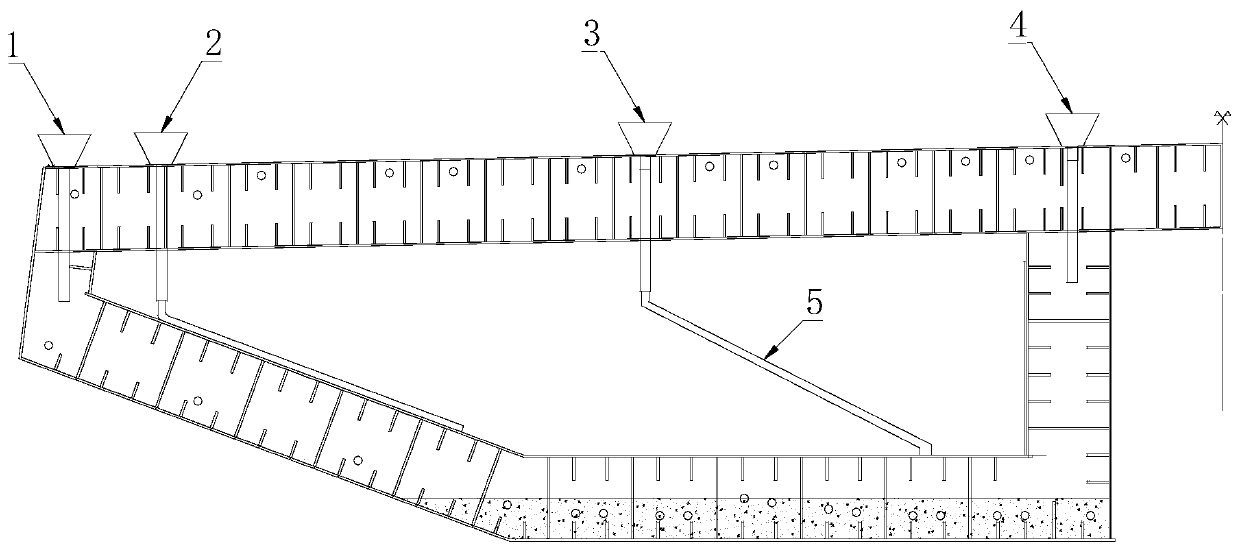

[0034] A construction method for a steel-concrete joint section of a long-span cable-stayed bridge, such as Figure 1 to Figure 7 As shown, including the following construction steps:

[0035] First, according to the construction arrangement, install the longitudinal prestressed tendons 9 of the concrete beam and finely adjust the concrete beam section 6; The concrete beams are docked and temporarily locked, and the joint between the two forms a steel-concrete joint section 8; the RPC concrete is mixed at the mixing station and transported to the site by a concrete tanker. Since the holes are reserved on the steel box girder, the concrete inside the steel girder is poured directly through the lower hopper, which avoids the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com