An ultra-high temperature long-term mechanical property testing system equipped with heat-insulated air-cooled fixtures

A test system, ultra-high temperature technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of long-term mechanical performance testing of ultra-high temperature structural materials that are almost empty and cannot meet urgent needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

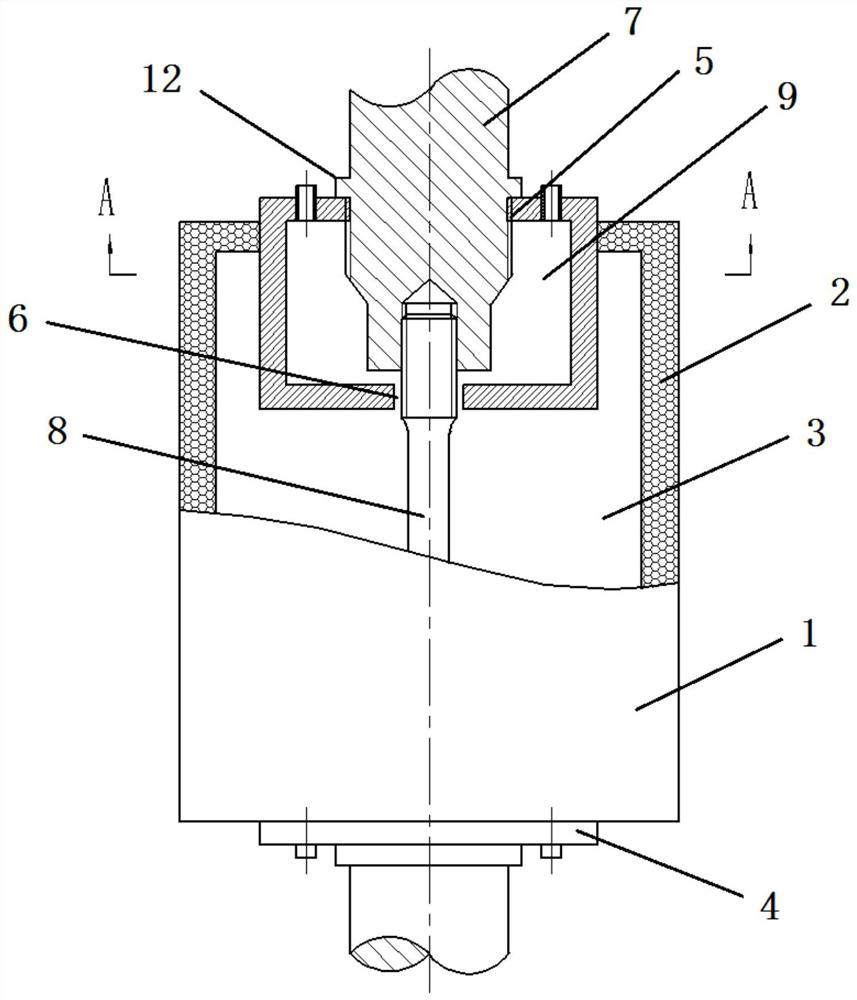

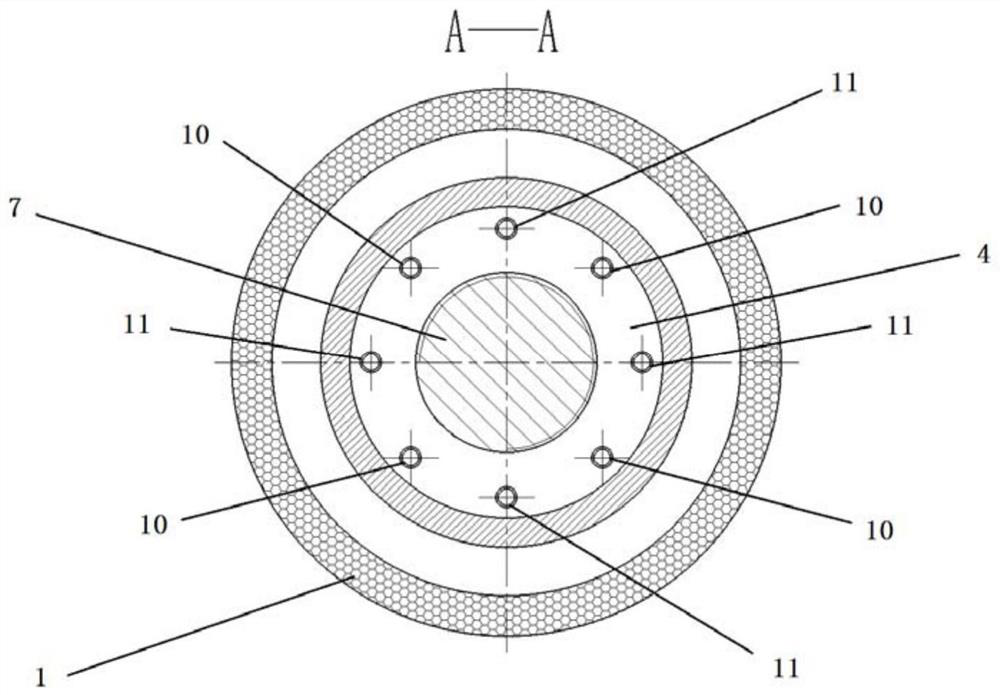

[0018] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0019] Refer to attached Figure 1-Figure 2 As shown, the ultra-high temperature long-term mechanical testing system equipped with heat-insulated air-cooled fixture mainly includes ultra-high-temperature heating furnace 1, heat-insulated air-cooled fixture 4, and transition fixture 7. The ultra-high temperature heating furnace 1 includes two parts: a furnace body 2 and a furnace cavity 3 . The overall structure of the furnace body 2 is cylindrical, and a pair of heat-insulating air-cooled fixtures 4 are installed at the upper and lower ends. The principle of determining the diameter and length of the furnace cavity 3 is to ensure a predetermined temperature and a sufficiently long uniform temperature zone. . The heat-insulating air-cooling fixture 4 has a cylindrical structure, and a high-temperature seal is used between the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com