Pollution flashover test method for simulating erosion and ageing of RTV coating on insulator surface

A test method and insulator technology, applied in the direction of testing dielectric strength, measuring devices, instruments, etc., can solve the problems of complex equipment, long time-consuming, long test cycle, etc., and achieve the effect of preventing flashover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A pollution flashover test method for simulating the corrosion and aging of the RTV coating on the surface of an insulator, comprising the following steps in sequence:

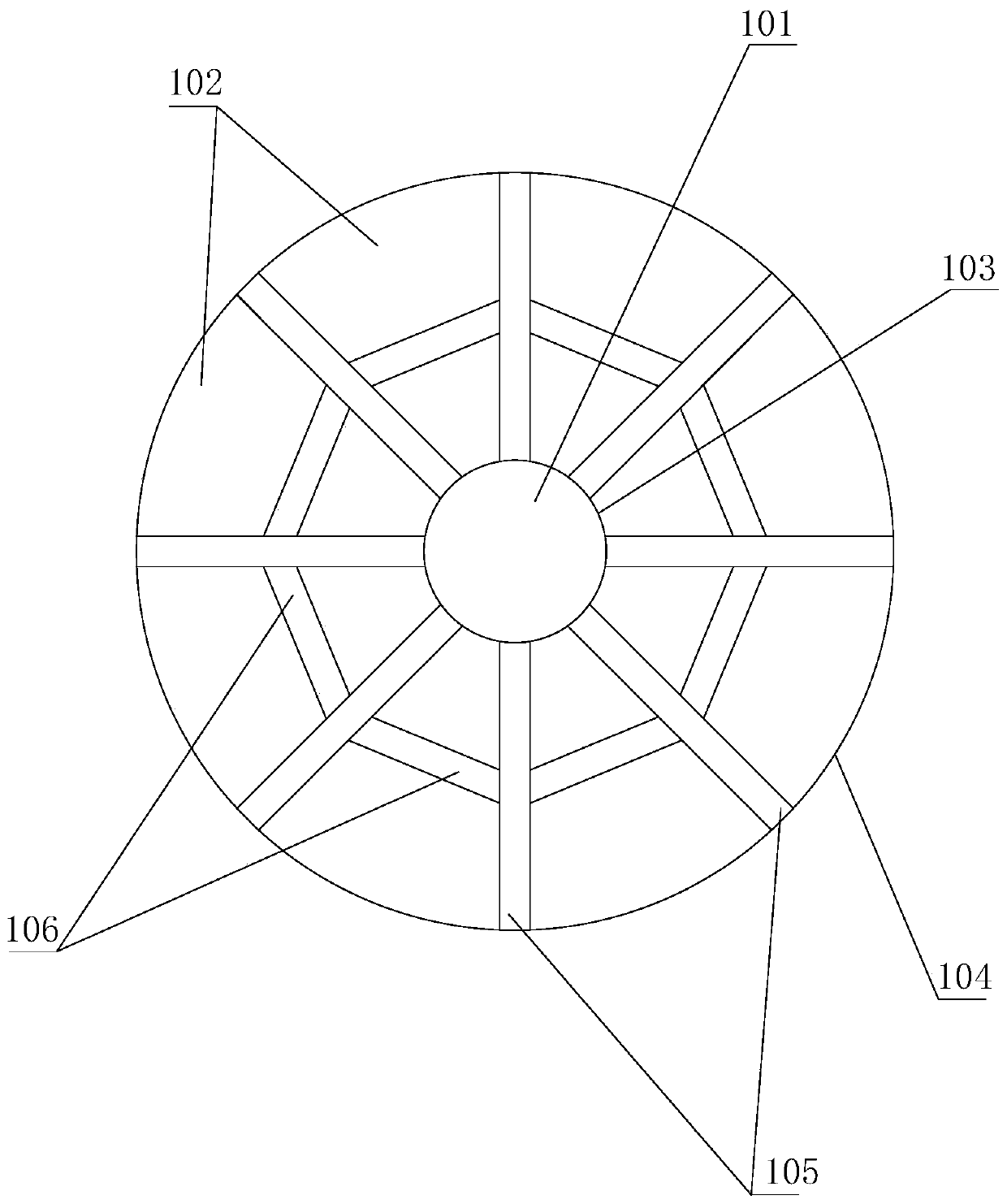

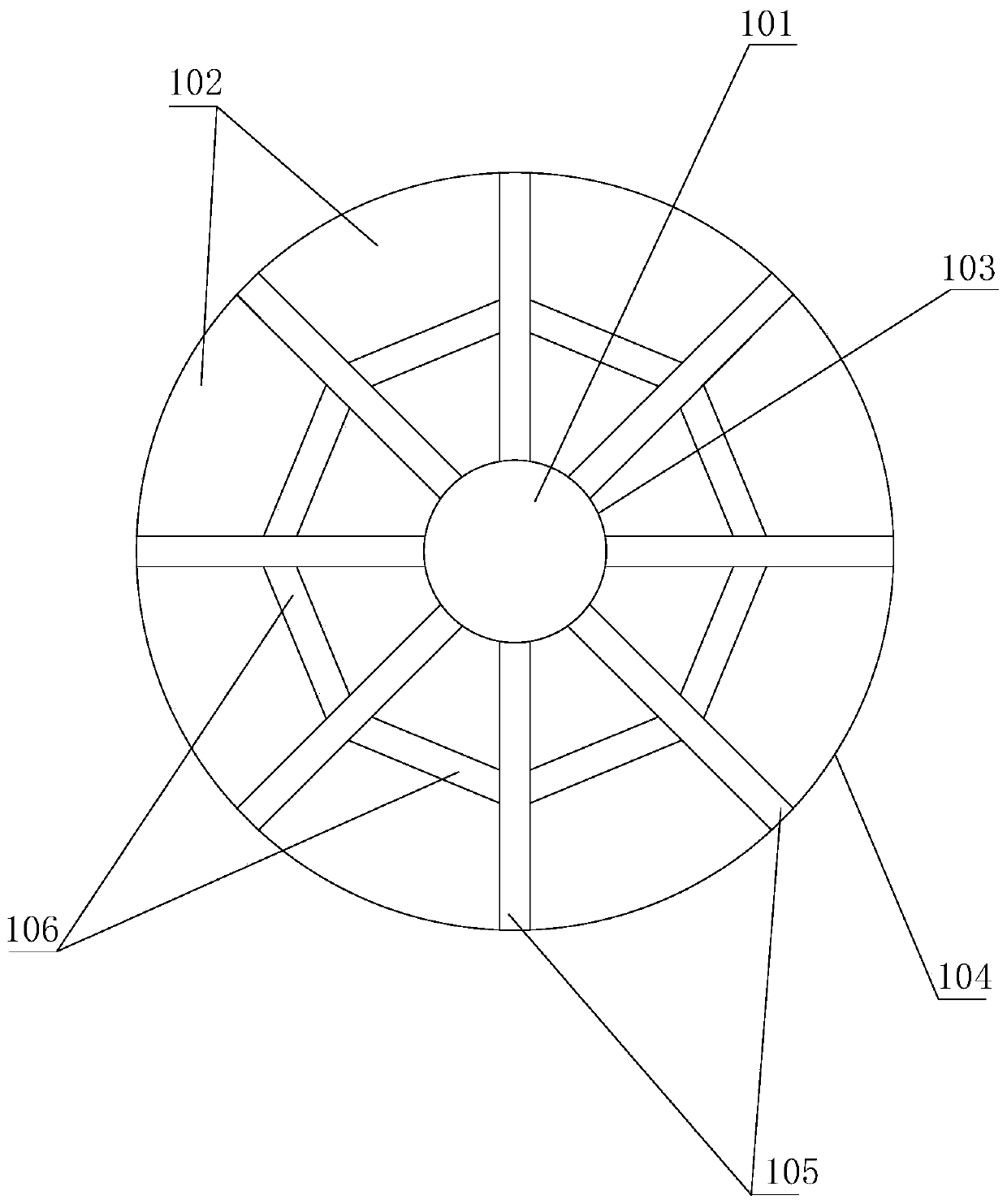

[0038] 1) completely wrapping the insulator coated with RTV coating with flexible thermal insulation material 102;

[0039] 2) Select a strip-shaped area on the outer surface of the flexible heat insulating material 102;

[0040] 3) Cut and remove the flexible heat insulating material 102 at the elongated area with a cutter, and the area on the outer surface of the RTV coating exposed in the elongated hole formed after cutting is the simulated erosion and aging zone;

[0041] 4) Burn the outer surface of the RTV coating at the simulated corrosion aging zone with a spray gun with a flame epitaxy temperature of 1000°C, and control the outer surface of the RTV coating to be damaged according to the actual corrosion and aging degree of the RTV coating in actual online operation. The final degree of burning...

Embodiment 2

[0044] On the basis of the above-mentioned embodiment 1, further preferably, in step 2), the selection method of the elongated area on the outer surface of the flexible heat insulating material 102 on the shed of the insulator is: in the flexible heat insulating material 102 Determine a starting point every interval a on the inner diameter line of the annular outer surface, and determine n starting points in total;

[0045] Taking the direction perpendicular to the outer diameter edge 104 of the shed from the starting point as the vertical erosion aging direction, draw a line along the vertical erosion aging direction on the outer surface of the flexible heat insulating material 102 to make a vertical direction with a width b In the strip-shaped area, the flexible heat insulating material 102 at the vertical strip-shaped area is cut and removed to form a vertically strip-shaped hole, and the area on the outer surface of the RTV coating exposed in the vertically strip-shaped hol...

Embodiment 3

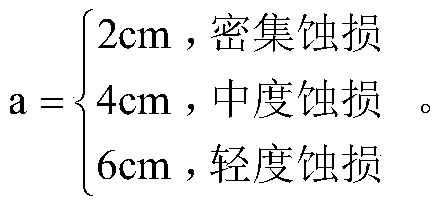

[0048] On the basis of the above-mentioned embodiment 2, further preferably, in step 2), the interval a is determined according to the density of the actual erosion and aging of the RTV coating on the simulated on-line running insulator:

[0049]

[0050] The meaning of the formula in this embodiment 3 is: when the actual corrosion and aging intensity of the RTV coating on the simulated on-line insulator is intensive corrosion, a=2cm; when the simulated on-line operation When the actual corrosion and aging intensity of the RTV coating on the insulator is moderate corrosion, a=4cm; when the actual corrosion and aging intensity of the RTV coating on the simulated on-line operating When damaged, a=6cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com