A kind of Fritillaria harvester

A harvester and Fritillaria technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high labor intensity, low reference value, and low output of Fritillaria, reducing cost input, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

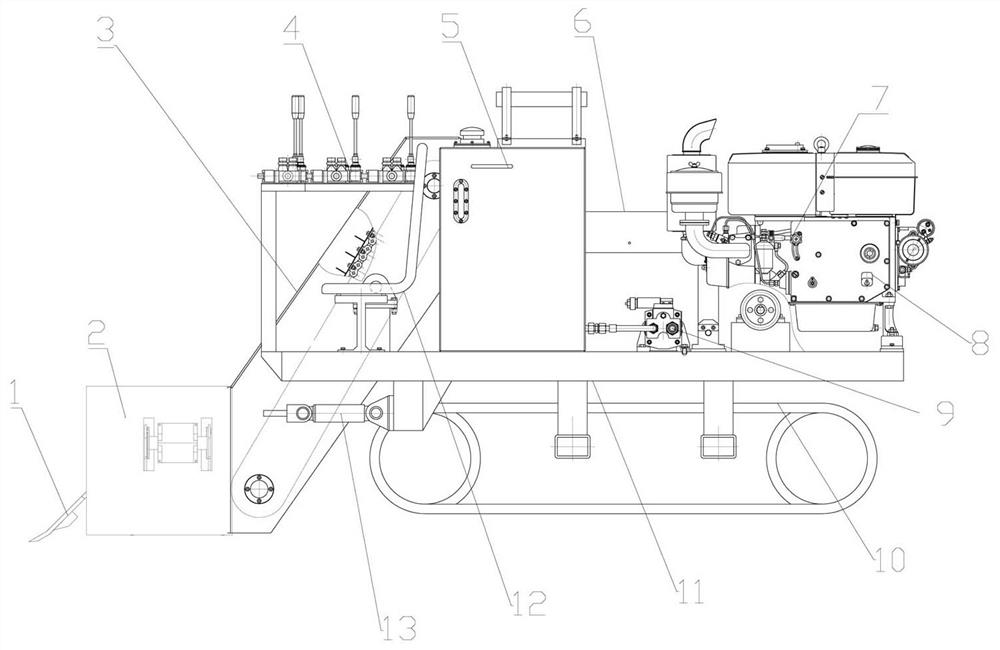

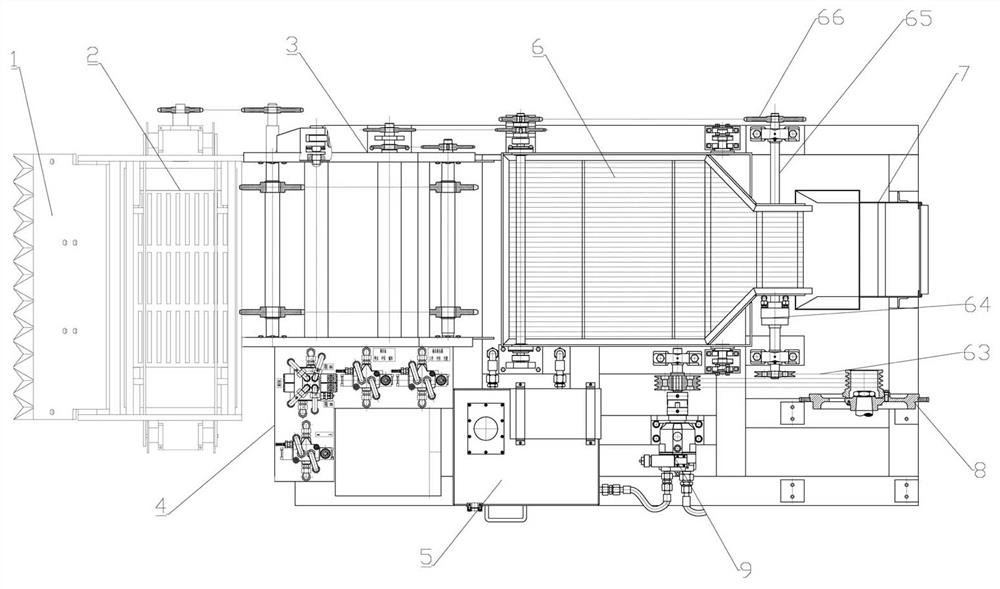

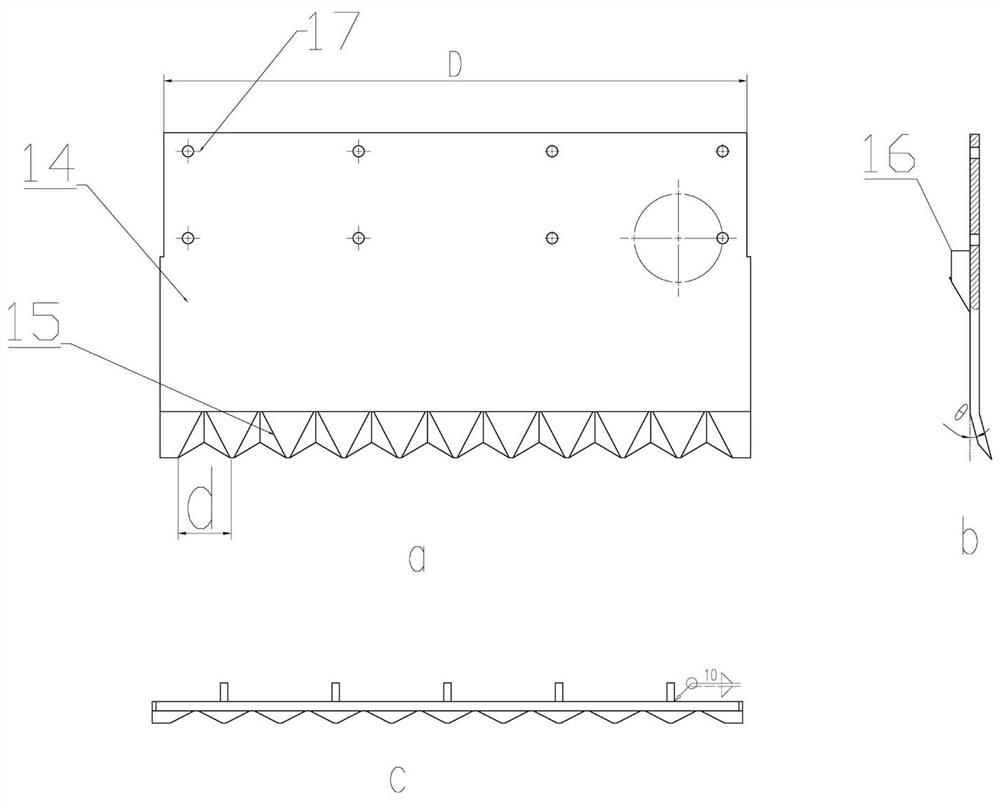

[0025] Such as figure 1 Shown, the Fritillaria harvester that the present invention proposes, its main vehicle frame 11, loading mechanism, vibrating screen 6, power mechanism and receiving hopper 7 form. Among them, the loading mechanism is composed of excavating shovel 1, soil crusher 2 and chain conveyor 3; the power mechanism is composed of diesel engine 8, hydraulic pump 9, hydraulic control valve 4, rubber track 10 and hydraulic cylinder 13. The excavating shovel 1 is located at the front end of the vehicle frame 11, the crusher 2 is located between the excavating shovel 1 and the chain conveyor 3, the inlet end is connected with the excavating shovel 1, the outlet end is connected with the chain conveyor 3, and the chain conveyor 3 At the rear end 2 of the soil crusher, it is installed on the vehicle frame 11 at 60° with the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com