Novel indexing working turntable of numerical control milling and boring machine

A CNC milling and boring machine technology, which is applied to parts, manufacturing tools, and large fixed members of boring machines/drilling machines. The effect of fast and convenient work, convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

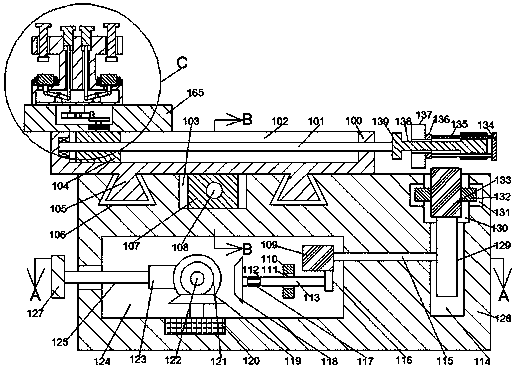

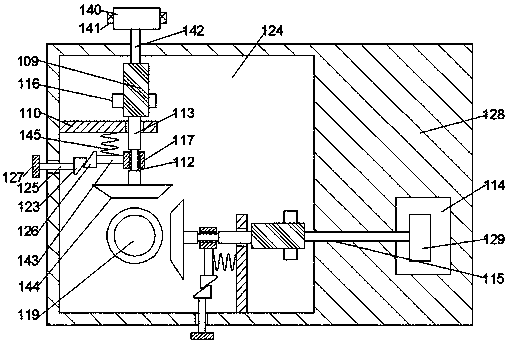

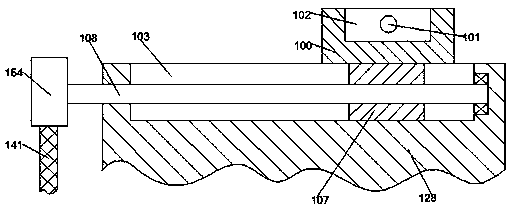

[0020] Such as Figure 1-4 As shown, for the convenience of description, the following directions are stipulated as follows: figure 1 The projection relationship itself is the same up and down, left and right, front and rear directions. The new indexing work turntable of a CNC milling and boring machine of the present invention includes a CNC milling and boring machine processing table 128 and a tool holder rail 100 extending left and right on the CNC milling and boring machine processing table 128. , The upper end of the tool holder rail 100 is slidingly connected with a tool holder mechanism, the right end of the tool holder slide rail is provided with a connecting mechanism, the CNC milling and boring machine processing table 128 is provided with a conversion cavity 124, and the bottom inner wall of the conversion cavity 124 A first motor 120 is embedded. The end of the output shaft of the first motor 120 is fixedly connected with a driving bevel gear 119. The front end and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com