Ultrasound-assisted resistance spot-welding device and method used for sheet metal materials

A resistance spot welding and ultrasonic-assisted technology, applied in the field of welding manufacturing, can solve problems such as large changes, electrode wear, and complicated devices, and achieve the effects of small ultrasonic vibration resistance, promotion of mass transfer and heat transfer, and high method adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

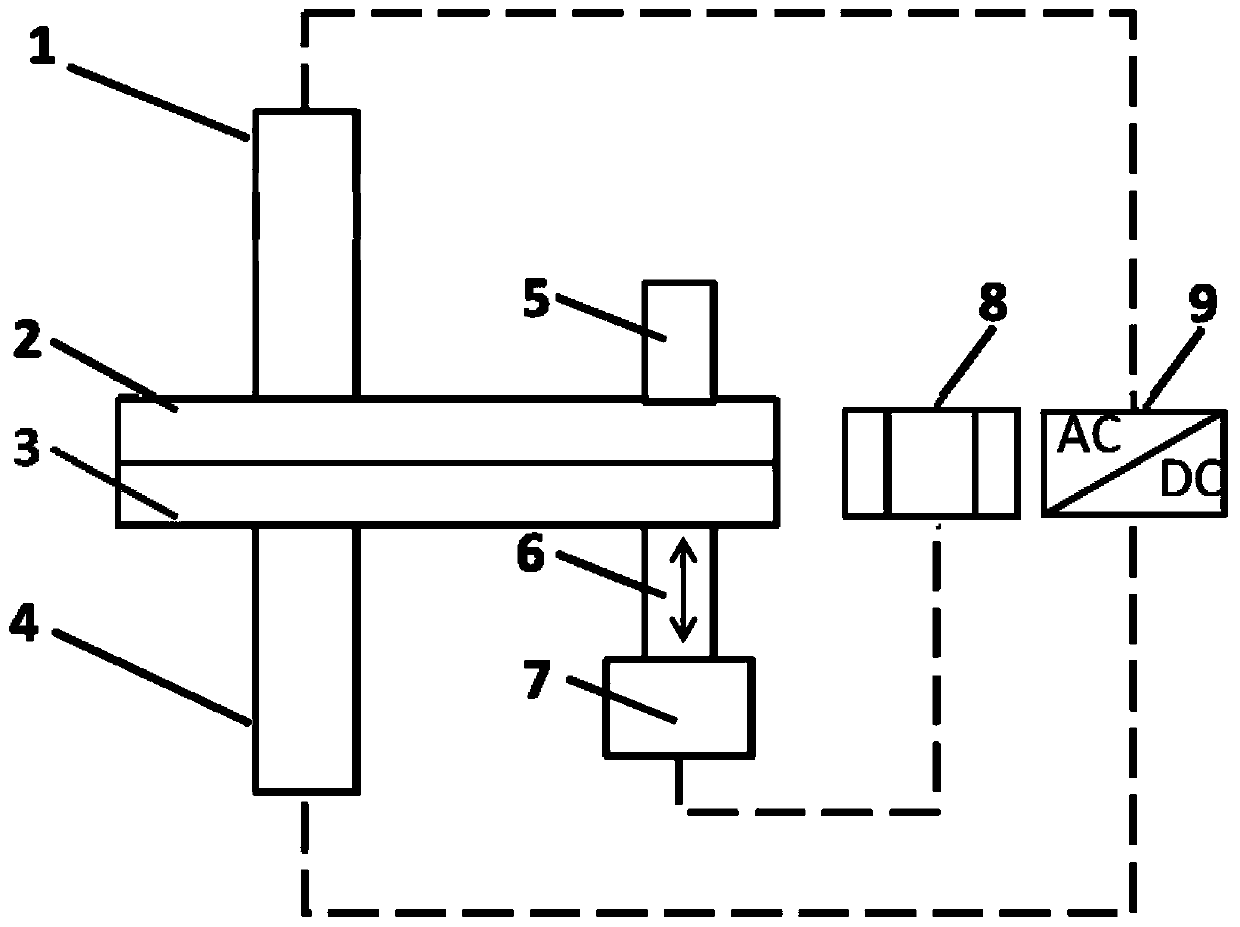

[0035] In the ultrasonic-assisted resistance spot welding device of this embodiment, the diameters of the upper electrode 1 and the lower electrode 4 are both 8 mm. The ultrasonic tool head 6 has a diameter of 5 mm, and is in contact with the workpiece at a position 10 cm away from the axis of the lower electrode 4 . The distance between the ultrasonic tool head 6 and the lower electrode 4 can effectively ensure that the ultrasonic energy acts on the nugget without interference between the ultrasonic tool head 6 and the lower electrode 4 . According to different welding materials, the end face of the ultrasonic tool head 6 can be flat or provided with patterns or micro-teeth, so as to ensure effective transmission of ultrasonic vibrations. The angle between the ultrasonic tool head 6 and the workpiece to be welded can be between 0° and 90°.

[0036] The ultrasonic generator 8 and the transducer 7 are commonly used devices in the field of ultrasonic waves, which generate reson...

Embodiment 2

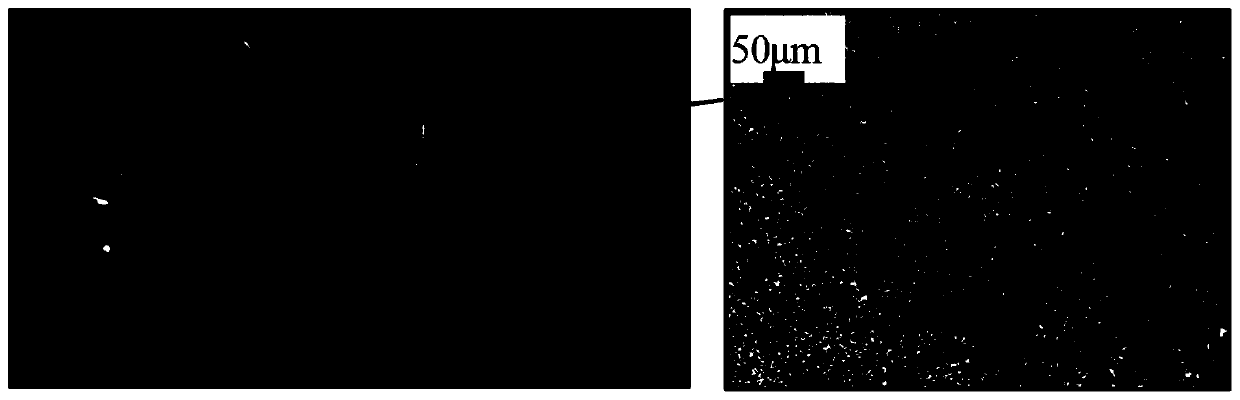

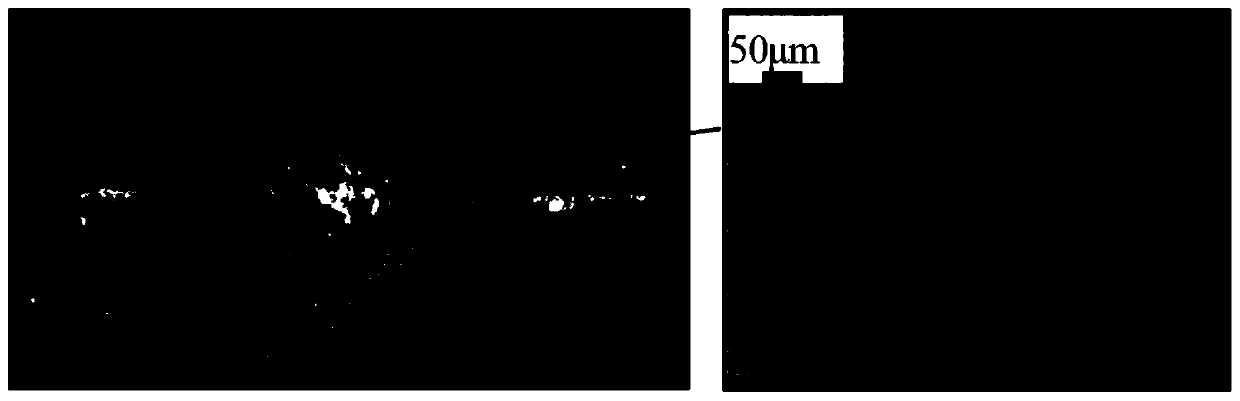

[0048] In this embodiment, the same ultrasonic-assisted resistance spot welding device as in Embodiment 1 is used to spot weld two 6061 aluminum alloy plates with a thickness of 1 mm. The specific operation steps are as follows:

[0049] 1) Preloading stage:

[0050] The upper electrode 1 exerts a pressure of 1.2kN on the upper plate 2 of the workpiece to be welded under the control of the pressure device Ⅰ, adjust the limit device 5 to make it contact the upper plate 2, and the ultrasonic tool head 6 exerts pressure on the welded workpiece under the control of the pressure device II. The lower plate 3 of the part applies a pressure of 50N, so that the resistance spot welding electrode and the ultrasonic tool head are in close contact with the workpiece to be welded. Keeping the pressure of the upper resistance spot welding electrode 1 and the ultrasonic tool head 6, turn on the ultrasonic generator 8 to make the ultrasonic tool head 6 vibrate, the ultrasonic vibration frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com