Abrasive water jet cutting nozzle and application thereof

A technology of abrasive water jet and spray head, which is applied in the direction of abrasives, abrasive feeding devices, spray guns, etc., can solve the problems of continuous operation, segmental milling, and increased cost of use, so as to improve cutting efficiency and facilitate The effect of production, ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

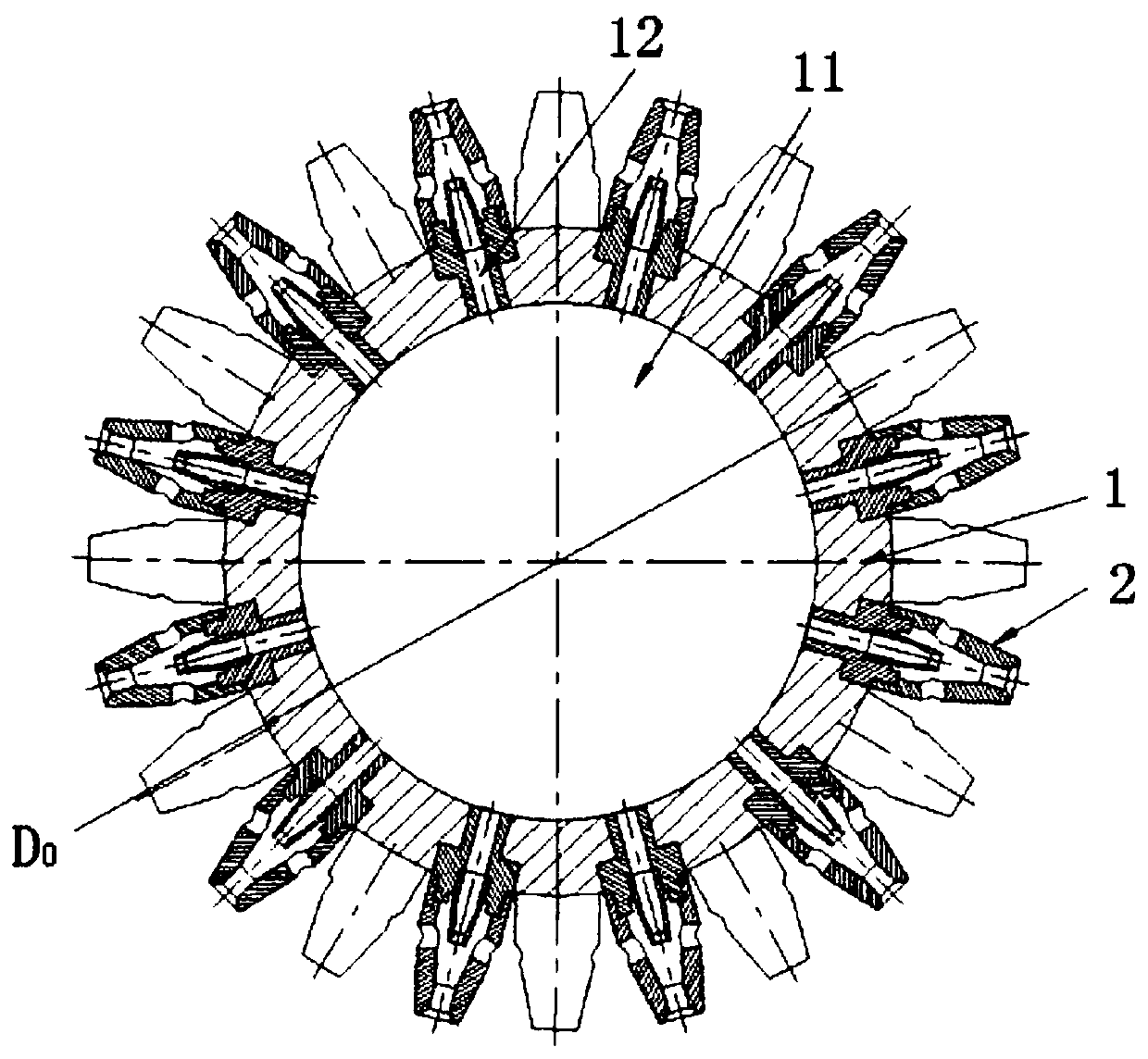

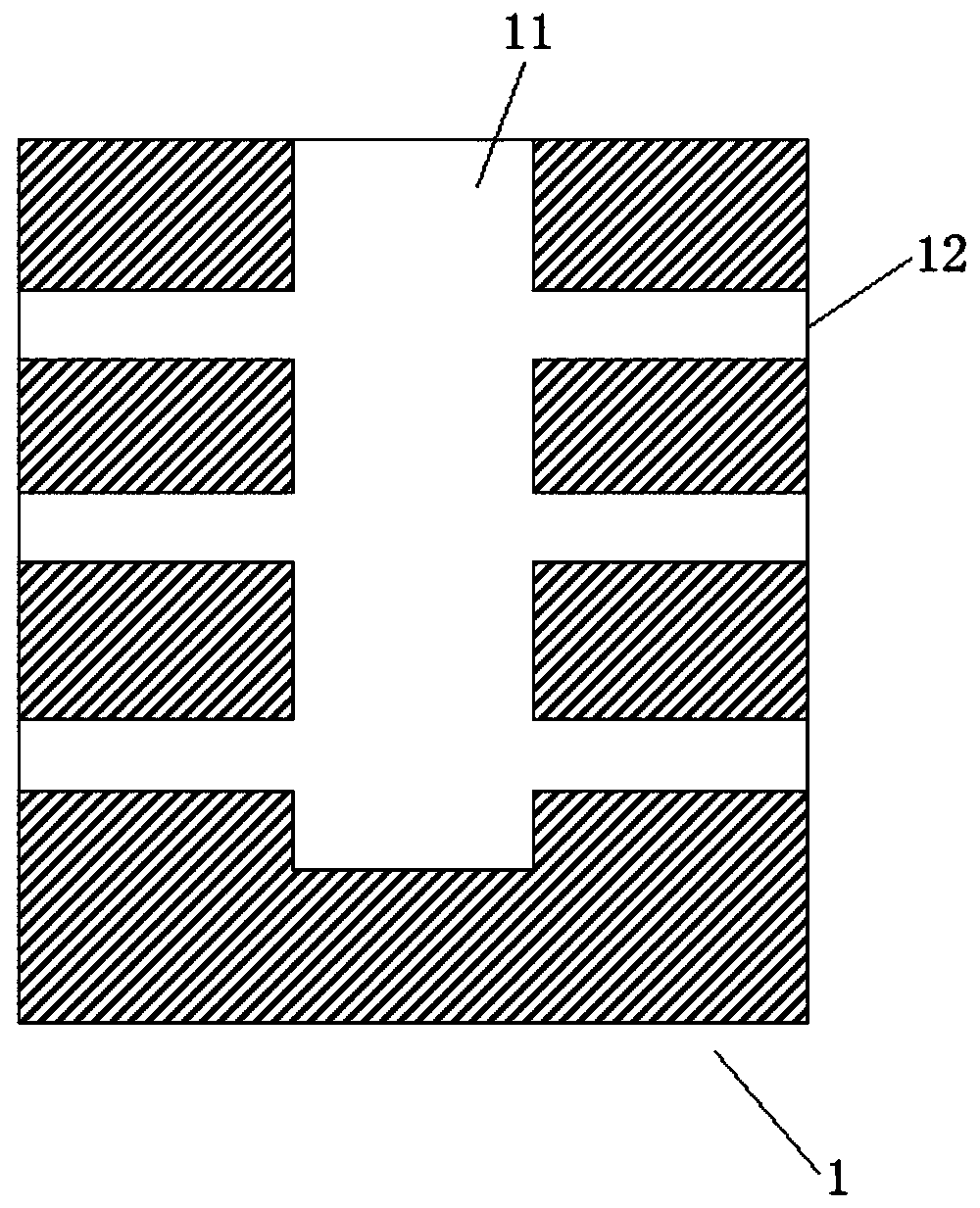

[0027] see Figure 1 to Figure 5 , the abrasive water jet cutting nozzle shown includes a nozzle body 1, the nozzle body 1 is provided with axial blind holes 11, and on multiple radial planes of the nozzle body 1, a plurality of axial The nozzle holes 12 connected to the blind holes 11 are arranged alternately on adjacent radial planes, and each nozzle hole 12 is provided with a nozzle 2 . The setting of the axial blind hole 11 ensures that the fluid can enter the nozzle 2 from the radial direction, so that the movement direction of the fluid is perpendicular to the axis of the nozzle body 1, thereby realizing the radial cutting of the downhole casing.

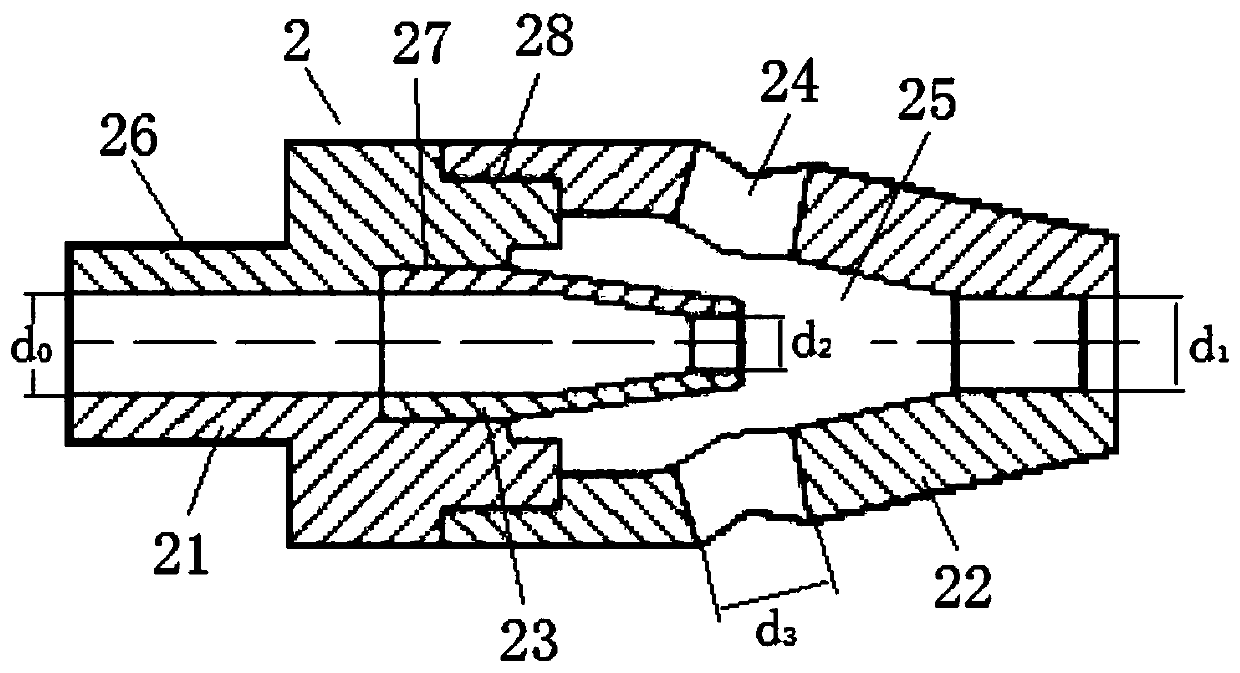

[0028] The nozzle 2 includes a coaxially arranged base 21, an outer nozzle 22 and an inner nozzle 23, the base 21 is provided with an axial through hole, one end is provided with a first external thread 26 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com