Process for UASB (Upflow Anaerobic Sludge Blanket) treatment on landfill leachate

A technology for landfill leachate and leachate, which is applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high treatment difficulty, poor ammonia nitrogen removal effect, and reduced biodegradability, etc. The effect of operating cost, reduction of subsequent treatment load, and high ammonia nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

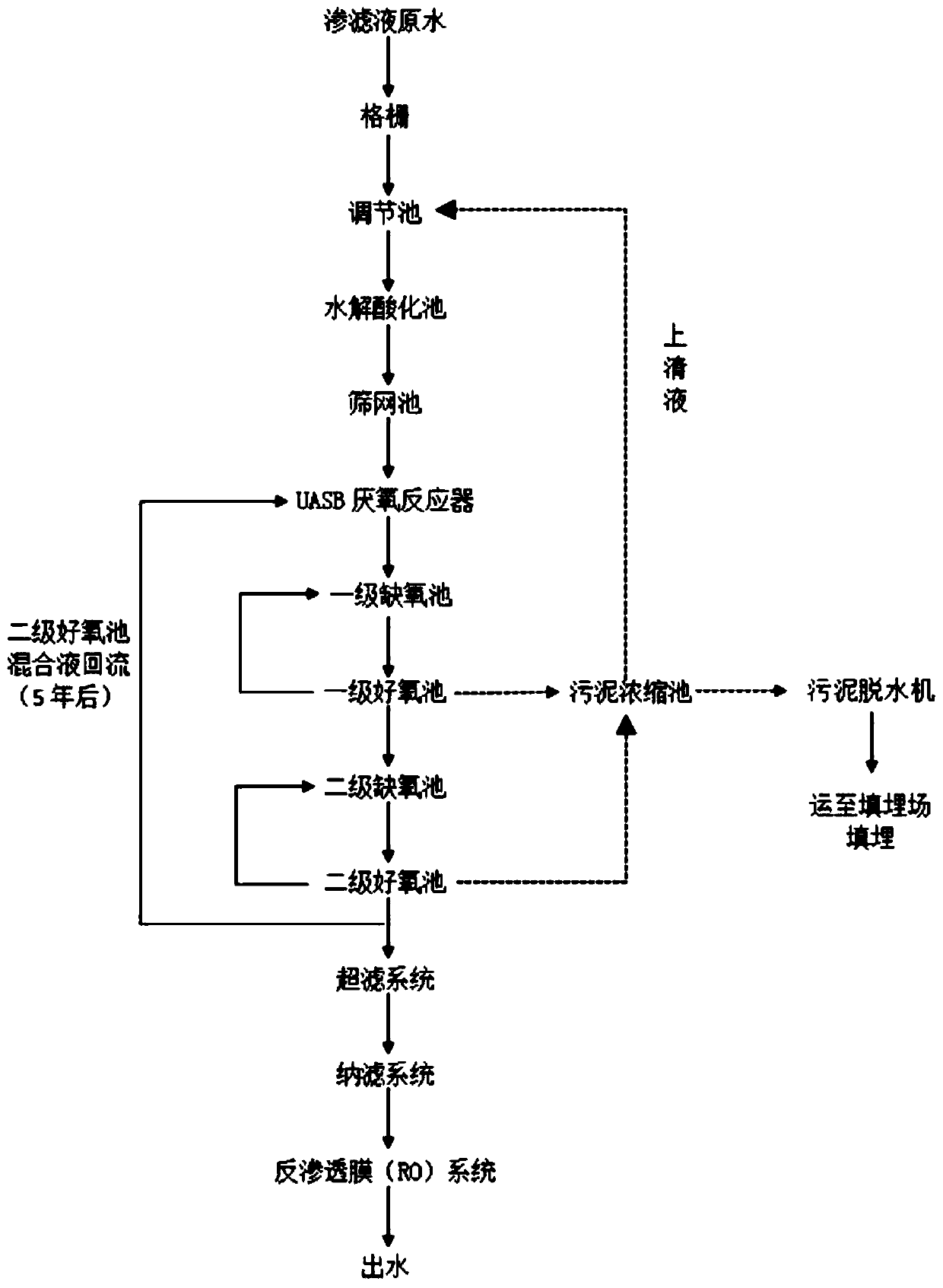

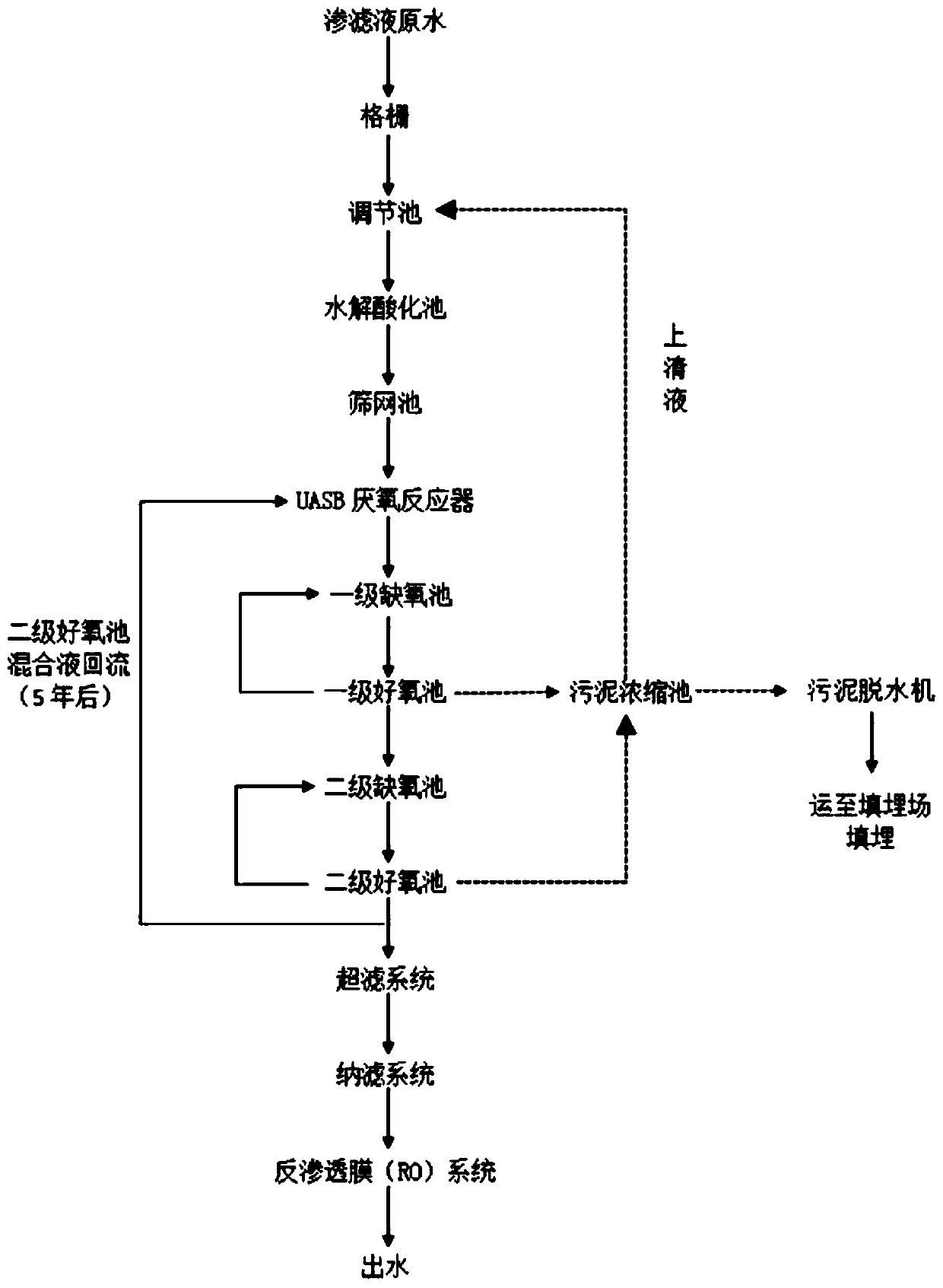

[0022] A process suitable for UASB treatment of landfill leachate, such as figure 1 As shown, the specific process is as follows:

[0023] In the first step, the landfill leachate is collected through the collection pipe, and then the collected landfill leachate passes through the stainless steel fine grid installed at the entrance of the adjustment tank to separate solid impurities and then enters the leachate adjustment tank. Homogenous quality and quantity are obtained in the adjustment pool to ensure system stability;

[0024] In the second step, the effluent from the regulating tank flows into the hydrolysis and acidification tank. The hydrolysis and acidification bacteria in the hydrolysis and acidification tank can hydrolyze and acidify long-chain polymers into organic small molecule alcohols or acids with stronger biodegradability, and can also convert some non-biodegradable Or heterocyclic organic compounds with weaker biochemical properties can be broken down and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com