Rapid grouting construction method for fabricated concrete construction

A technology of concrete building and construction method, which is applied in the direction of buildings, building components, building structures, etc. It can solve the problems of restricting the rapid construction concept of prefabricated buildings, long grouting construction period, and prolonging the construction period, so as to speed up the grouting construction operation The effect of increasing the speed, improving the efficiency of grouting construction, and reducing the amount of cement

Pending Publication Date: 2019-07-19

武汉合创炬盛科技有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The sealing material generally uses cement-based mortar, which takes a long time to set, and is prone to leaks due to unreliable sealing. The sleeve grouting material also takes a long time to set, and it takes 24 hours to reach the predetermined strength requirement.

This form of technology leads to the extension of the construction period, which restricts the development of the rapid construction concept of prefabricated buildings

[0004] Therefore, it is of great significance to develop a method for rapid grouting construction of prefabricated concrete buildings and improve the current situation of long grouting construction period, which is of great significance for promoting and accelerating the development of prefabricated buildings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034] An early-strength type sleeve grouting material for steel bar connection, comprising the following components in weight percentage: 10% cement, 15% zeolite powder, 18% calcium hydroxide, 2.8% gypsum, 3% activated aluminum oxide, magnesium oxide 1.5%, interface enhancer 0.25%, inducer 4%, water reducer 0.45%, fine aggregate 45%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

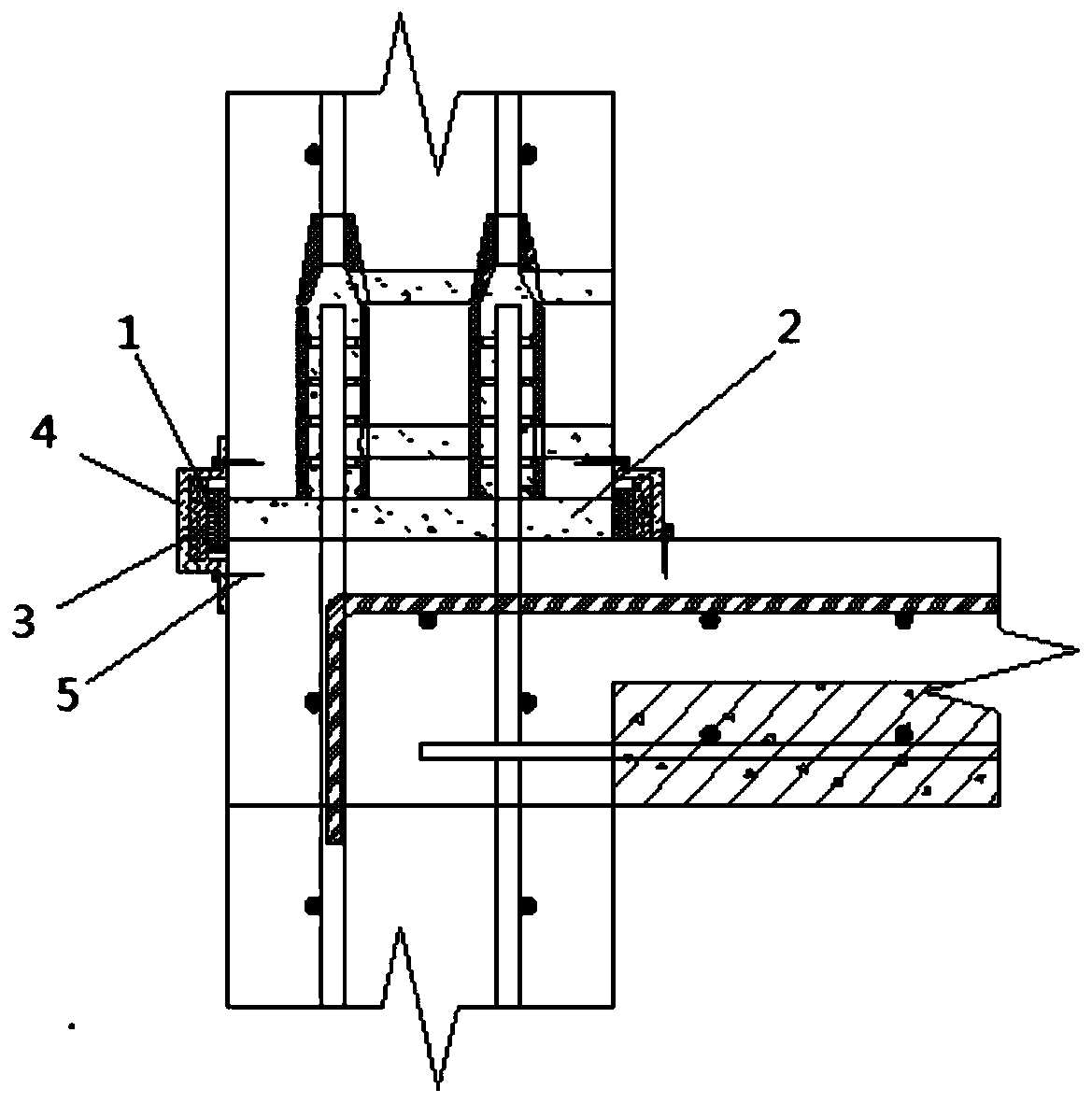

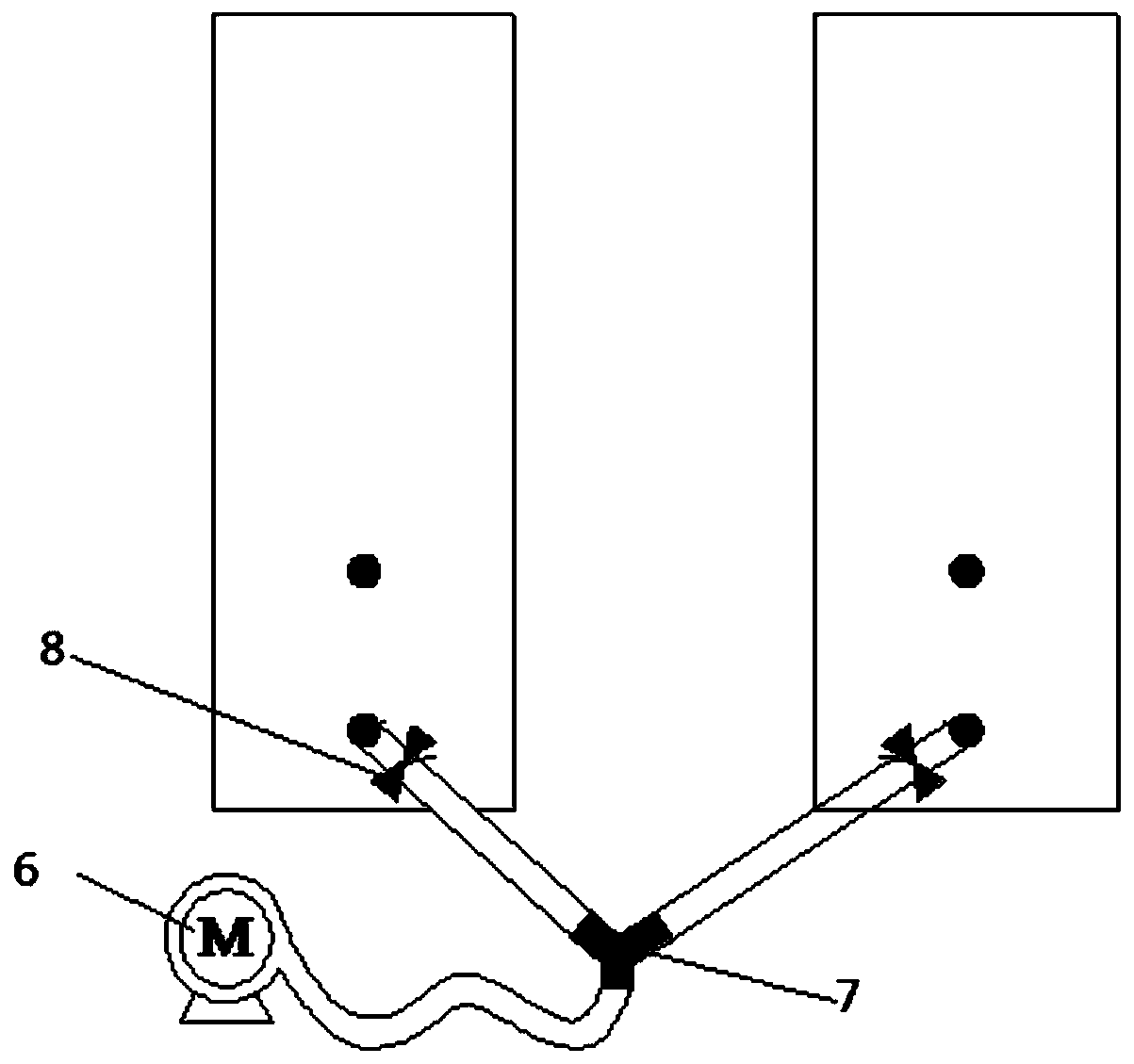

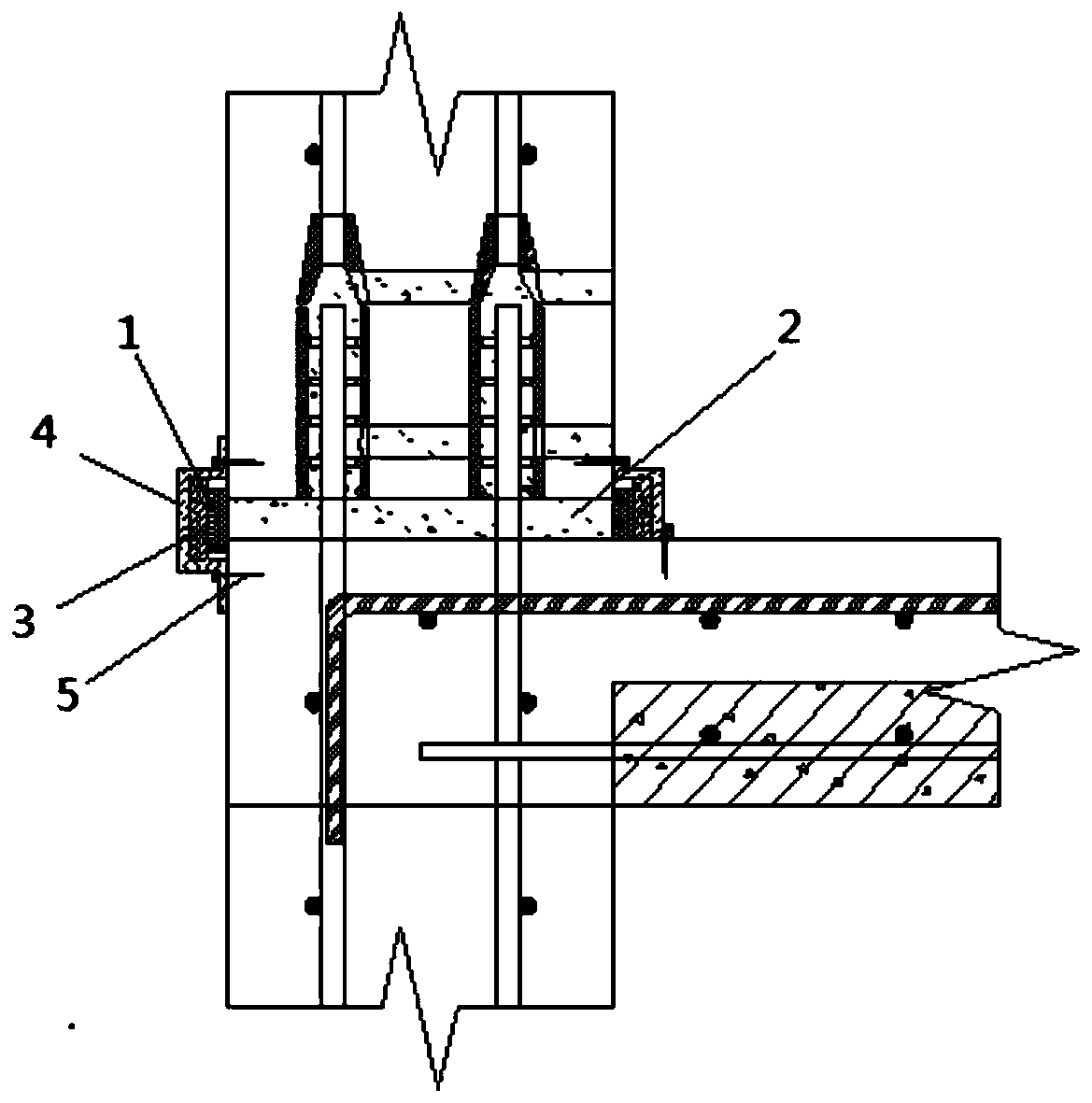

The invention discloses a rapid grouting construction method for fabricated concrete construction. The rapid grouting construction method comprises the following steps: step one, carrying out edge sealing on grouting cavities by an assembled edge sealing device; step two, uniformly stirring sleeve grouting material slurry used for connecting early strength reinforcing steel bars; step three, injecting the sleeve grouting material slurry used for connecting early strength reinforcing steel bars in the step two into the grouting cavities in the step one through a grouting machine. A multi-channel converter is used for injecting the uniformly stirred sleeve grouting material slurry used for connecting early strength reinforcing steel bars into a plurality of grouting cavities simultaneously,and the technical requirement that the compressive strength of the grouting material is 35 MPa within 2h can be achieved. The rapid grouting construction method can be widely applied to rapid groutingconstruction of fabricated concrete construction, and has the advantages of wide material acquisition range, simple and efficient construction, edge sealing material cyclic utilization, energy conservation, environmental protection and the like.

Description

technical field [0001] The invention relates to the technical field of prefabricated building construction, in particular to a rapid grouting construction method for prefabricated concrete buildings. Background technique [0002] In recent years, prefabricated integral concrete structures have been widely promoted and implemented in the field of construction because of their significant advantages in engineering quality, energy conservation, environmental protection, and social benefits. The advanced prefabricated component connection technology realizes the effective connection of the stressed steel bars of the assembled integral concrete structure. [0003] Usually, the construction process of steel bar sleeve grouting connection is mainly to seal the grouting chamber after the prefabricated components are installed and fixed on the construction site, and then use the sleeve grouting material mixture for sleeve grouting. Cement-based mortar is generally used as the sealin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04E04C5/16E04G21/02

CPCC04B28/04E04C5/165E04G21/02C04B2111/70C04B2201/50C04B14/047C04B14/303C04B14/304C04B14/02C04B22/064C04B22/143C04B2103/302C04B2103/0068

Inventor 杨国刚朱海军张克强韩贺阳

Owner 武汉合创炬盛科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com