Autoclaved aerated concrete integral insulation wallboard and its production process

A technology of autoclaved gas filling and thermal insulation wall panels, which is applied to walls, building components, buildings, etc., can solve the problems of inability to realize factory assembly production, cracking and leakage of walls, and slow construction speed, so as to solve the problems of wall The effects of cracking and leakage, fast construction speed and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

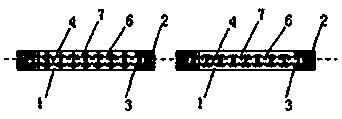

[0019] like figure 1 , 2 , 3, 4, 7, 8, and 9, the autoclaved aerated concrete integral thermal insulation wallboard provided by the present invention includes an autoclaved aerated concrete panel 1, a reinforced concrete frame 2, steel pins or / and bolts 3, Insulation layer 4, one side of the autoclaved aerated concrete slab 1 is provided with a groove 1a, and the other side is provided with a protrusion 1b, and the groove 1a is adapted to the protrusion 1b; or the two sides of the autoclaved aerated concrete slab 1 There are mutually symmetrical hole-forming grooves 1c on the side; or both sides of the autoclaved aerated concrete slab 1 are flat; the autoclaved aerated concrete slab 1 is assembled into a wall panel by horizontal installation, vertical installation or horizontal and vertical mixed installation 5. The wall panel 5 and the insulation layer 4 are assembled into the insulation wall panel 6; the two sides of the insulation wall panel 6 are wall panels 5, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com