A kind of high thermal conductivity transparent flexible composite film and preparation method thereof

A composite film and high thermal conductivity technology, applied in the field of high thermal conductivity transparent flexible composite film and its preparation, can solve the problems of low thermal conductivity, shorten the service life of electronic components, and the heat of electronic components is not easy to dissipate, etc. Thermal conductivity, effect of apparent light transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

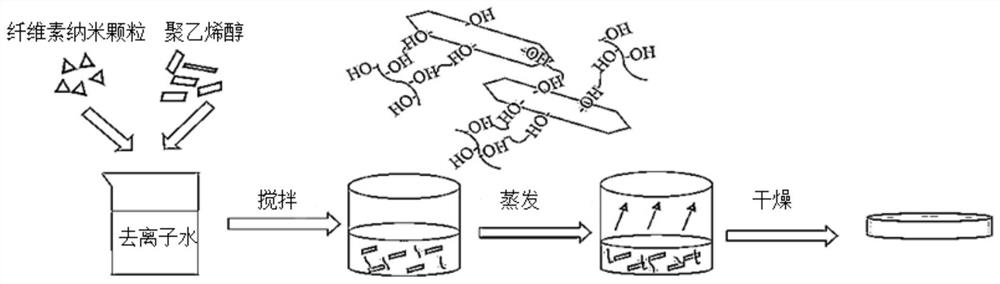

[0019] Such as figure 1 As shown, the present invention provides a kind of high thermal conductivity transparent flexible composite film and preparation method thereof, specifically comprising the following steps:

[0020] (1) Adding absorbent cotton to 80% concentrated sulfuric acid to prepare cellulose nanoparticles.

[0021] (2) Weigh polyvinyl alcohol with a mass ratio of 1 / 3-3 / 1 to the cellulose nanocrystalline particles, and measure 200 ml of deionized water with a beaker.

[0022] (3) Add the weighed polyvinyl alcohol and cellulose nanoparticles into 200ml of deionized water respectively, and after fully stirring for 15 minutes, a transparent and uniform aqueous solution is formed and then poured into the matrix container.

[0023] (4) Heat and evaporate the prepared solution at a temperature of 80-90° C. for 3-4 hours, and then completely dehydrate the water.

[0024] (5) Take out the dried mixture from the base container and put it into a hot press for hot pressing ...

Embodiment 1

[0027] (1) Adding absorbent cotton to 80% concentrated sulfuric acid to prepare cellulose nanoparticles.

[0028] (2) Weigh 1 g of cellulose nanoparticles and 3 g of polyvinyl alcohol, and measure 200 ml of deionized water with a beaker.

[0029] (3) Add 3 g of polyvinyl alcohol and 1 g of cellulose nanoparticles weighed into 200 ml of deionized water respectively, and after fully stirring for 15 min, a transparent and uniform aqueous solution is formed and then poured into a matrix container.

[0030] (4) Heat and evaporate the prepared solution at a temperature of 90° C. for 3.5 hours to completely dehydrate the water.

[0031] (5) Take out the dried mixture in the matrix container and put it into a hot press for hot pressing to form a flexible composite film with a thickness of 40 μm.

Embodiment 2

[0033] (1) Adding absorbent cotton to 80% concentrated sulfuric acid to prepare cellulose nanoparticles.

[0034] (2) Weigh 2 g of cellulose nanoparticles and 2 g of polyvinyl alcohol, and measure 200 ml of deionized water with a beaker.

[0035] (3) Add weighed 2g of polyvinyl alcohol and 2g of cellulose nanoparticles into 200ml of deionized water respectively, and after fully stirring for 15 minutes, a transparent and uniform aqueous solution is formed and then poured into the matrix container.

[0036] (4) Heat and evaporate the prepared solution at a temperature of 90° C. for 3.5 hours to completely dehydrate the water.

[0037] (5) Take out the dried mixture in the matrix container and put it into a hot press for hot pressing to form a flexible composite film with a thickness of 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com