Automatic installation structure and method of offshore wind power foundation anti-scour layer

An offshore wind power, automatic installation technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of difficulty in ensuring the quality of the anti-scour layer cast, and the risk of scouring around the pile is increased, and achieves good application prospects. The effect of riprap maintenance and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

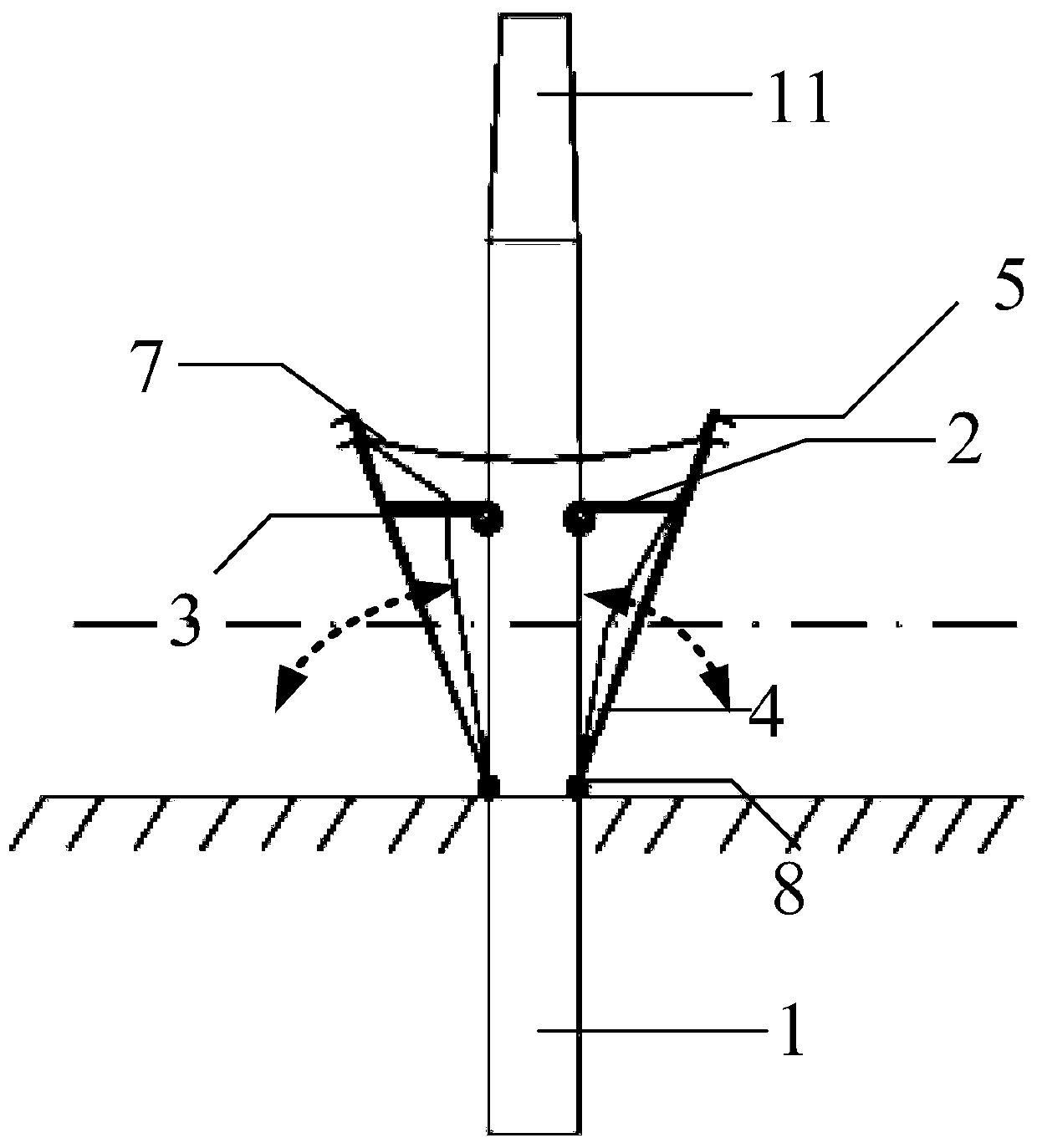

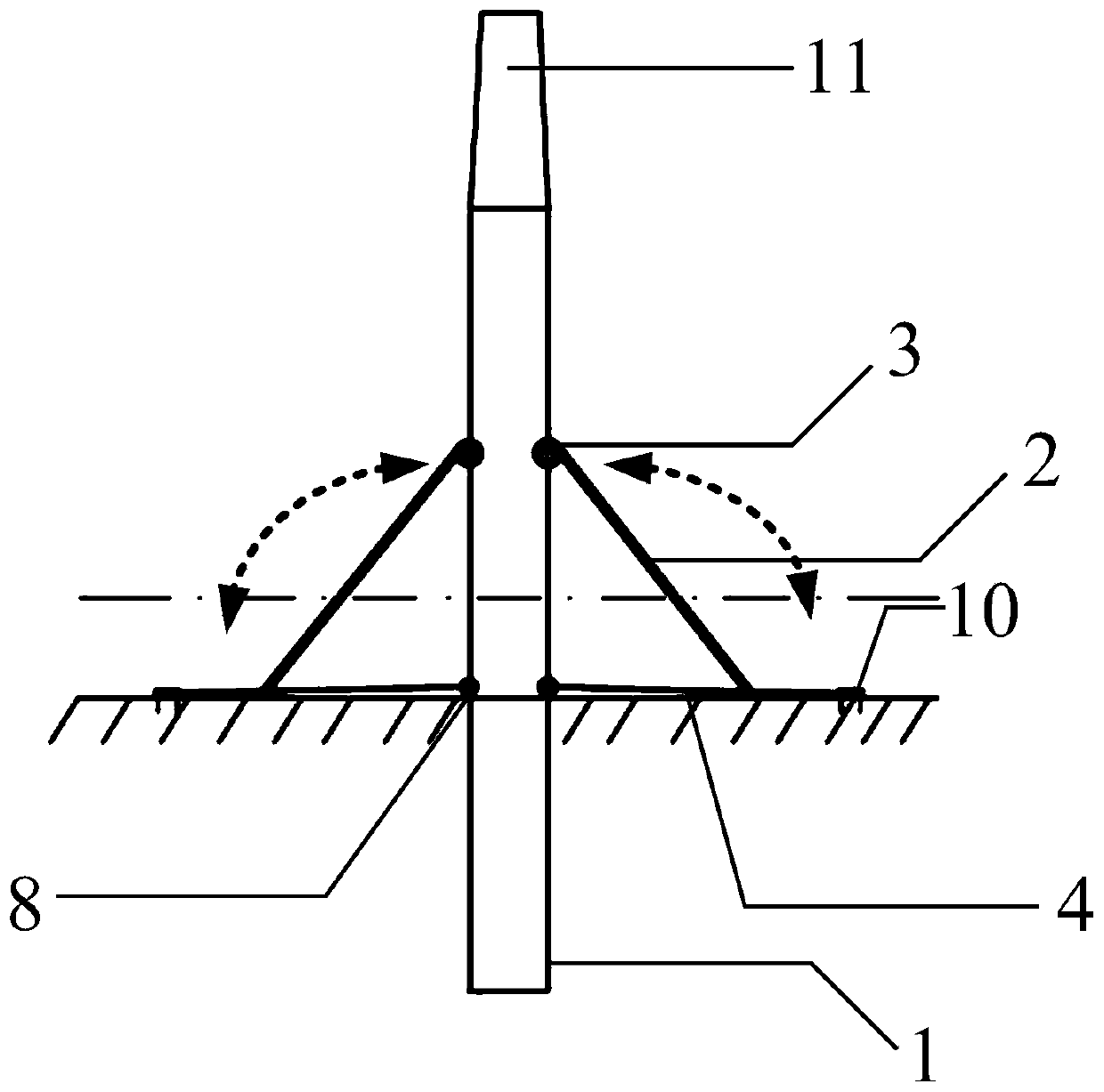

[0023] 1. The anti-scour layer automatic installation structure of offshore wind power monopile foundation, such as figure 1 The structure shown includes a single pile foundation 1, cables 2, pulleys 3, support rods 4, cylindrical foundation 5, honeycomb drainage holes 6, anti-scouring layer 7, and shaft wheels 8. Wherein one end of the cable 2 is fixedly connected with the upper part of the support rod 4, the end of the support rod 4 is fixedly connected with the cylindrical foundation 5, and the lower end of the support rod 4 is directly connected with the monopile foundation 1 through the shaft wheel 8, which can be rotated so that the support rod is unfolded or Packed up, wherein the support rod 4 and the cylindrical foundation 5 are welded by steel, the diameter of the cylindrical foundation is 1m, the downward end of the cylindrical foundation is open, and the upward end is closed to form a top cover 10, on the top cover of the cylindrical foundation Honeycomb drainage h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap