Method for correcting secondary reflector in tower type solar secondary reflection system

A technology of tower solar energy and secondary reflector, applied in solar heating system, solar thermal energy, solar ray concentration, etc., can solve the problem of restricting the large-scale development of primary reflecting tower solar thermal power generation, affecting the economy of power stations, and high operation and maintenance costs. problem, to achieve the effect of strong practicability, high precision and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

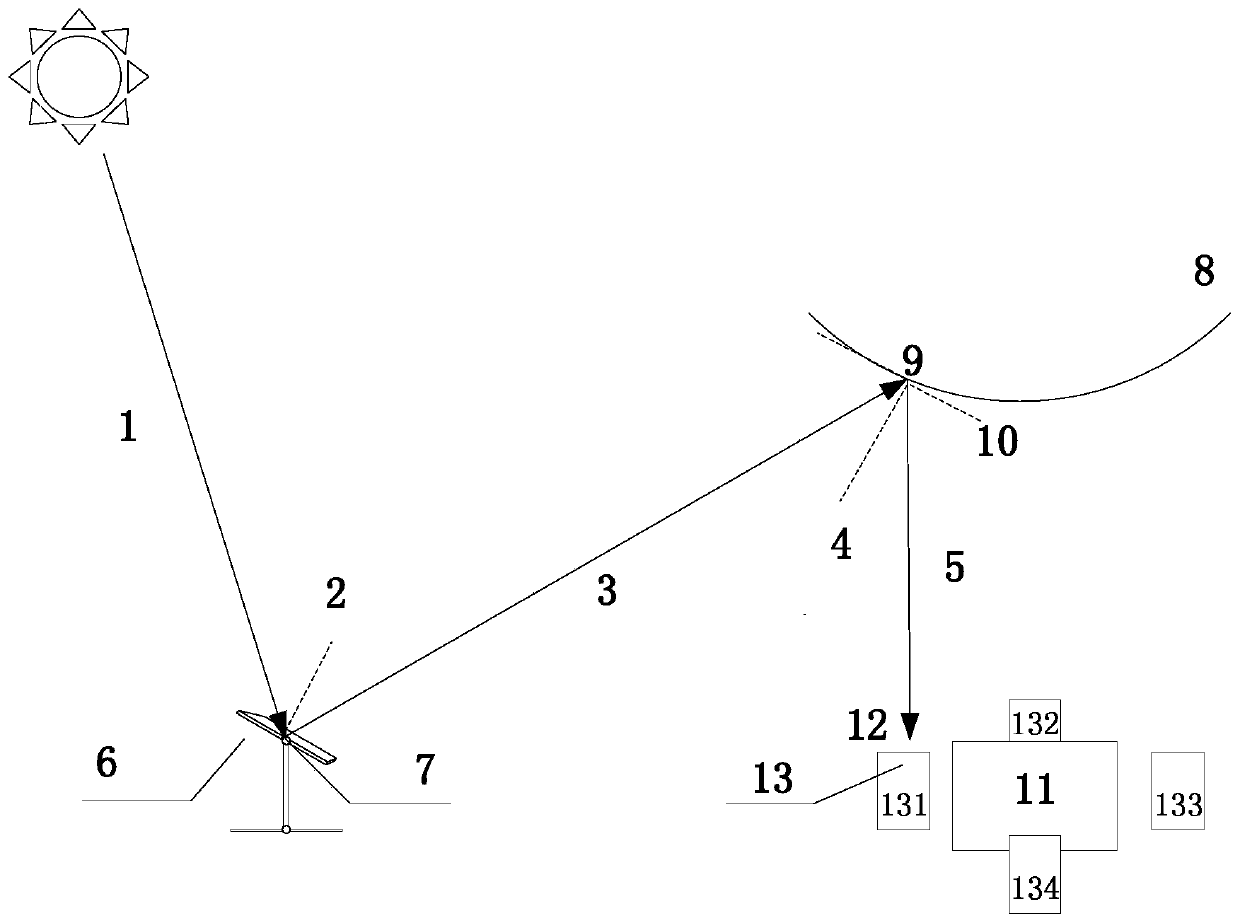

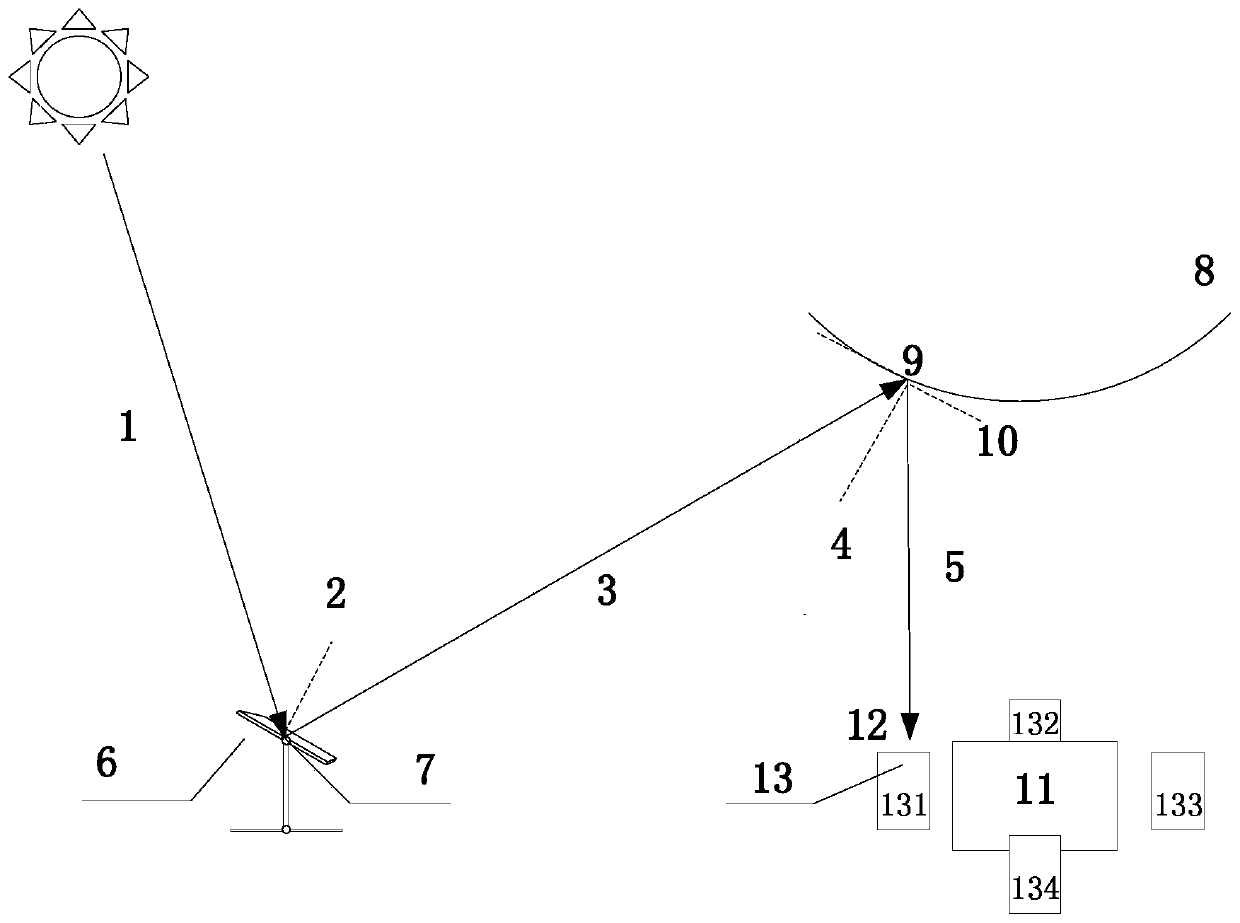

[0039] The invention relates to a method for correcting a secondary reflector in a tower type solar secondary reflector system. Such as figure 1 As shown, the tower type solar energy secondary reflection system is composed of a heliostat 6 , a secondary reflection mirror 8 , and a heat absorber 11 . Sunlight passes through the heliostat 6, and the light is reflected to the secondary reflector 8 located at a high place. After the secondary reflection, the light is reflected to the heat absorber 11 located on the ground, and finally realizes the conversion of light energy. This system avoids It eliminates the disadvantages of difficult and expensive operation and maintenance of traditional tower power stations that need to be equipped with high-lift circulating pumps and heat absorbers.

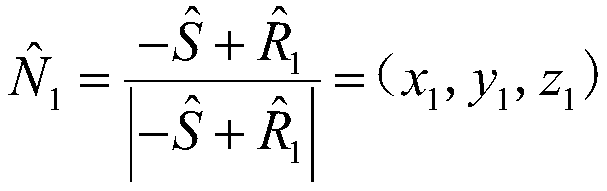

[0040] A method for correcting a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com