Calibration method for spatial position of laser beam

A calibration method and laser beam technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inability to determine the spatial position, not suitable for wide application, etc., and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

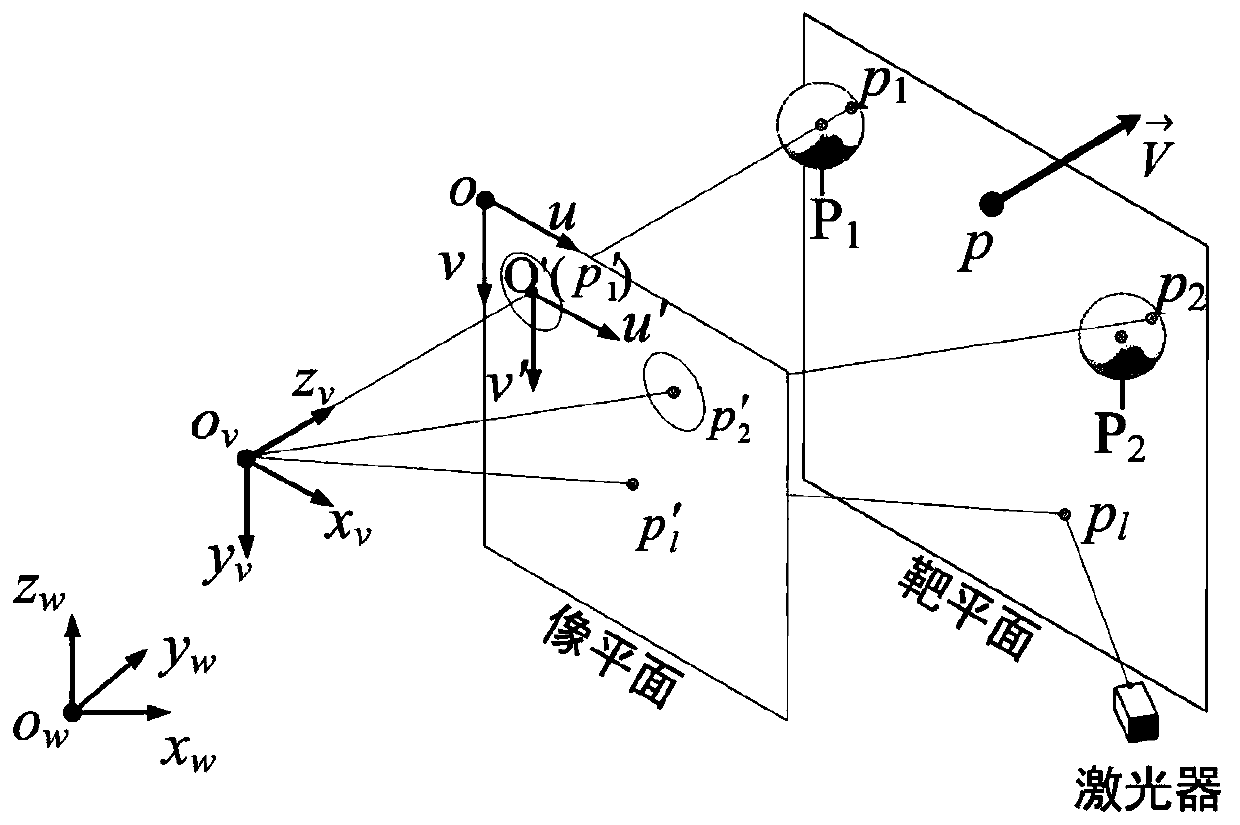

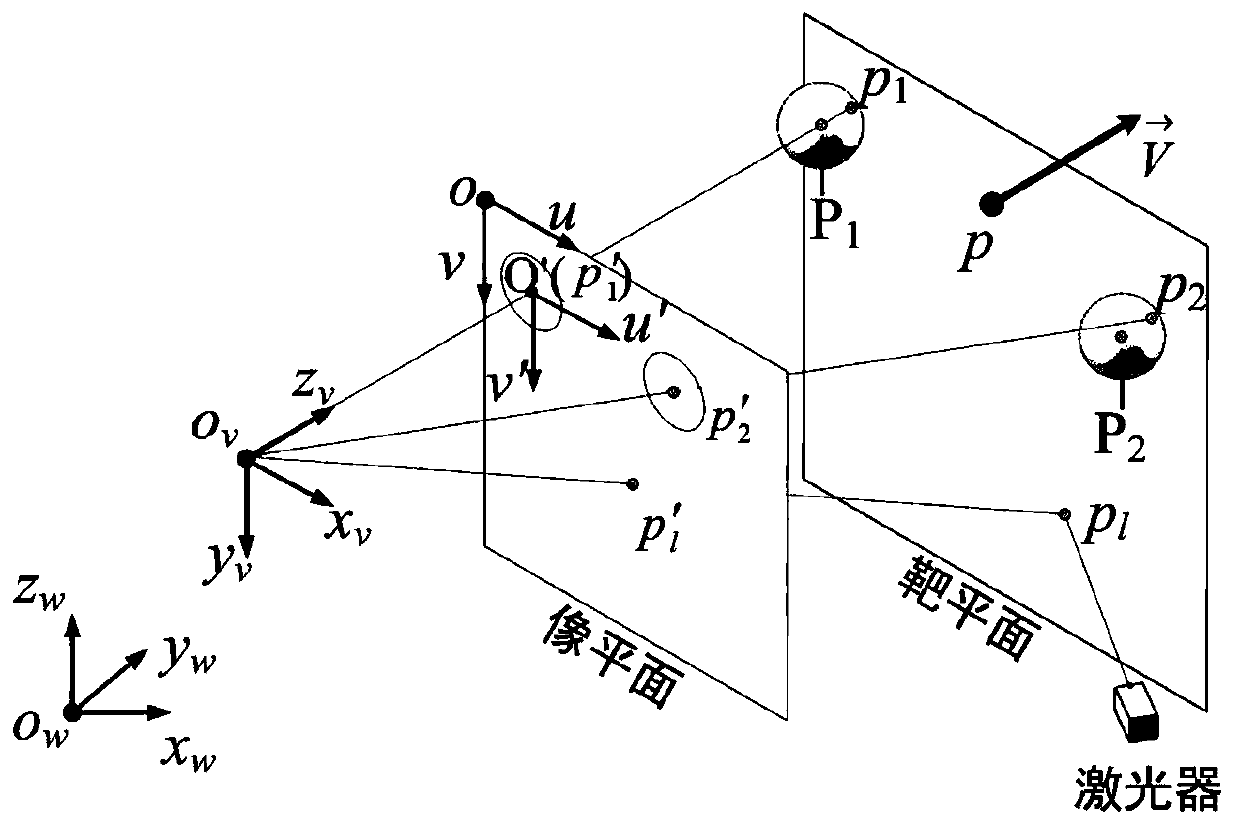

[0020] Such as figure 1 As shown, the point p on the target plane 1 ,p 2 ,p l are projected onto the image plane as points p 1 ', p' 2 ,p l '.

[0021] In order to express more clearly, the coordinate representation of each point in each coordinate system is shown in Table 1:

[0022] Table 1

[0023]

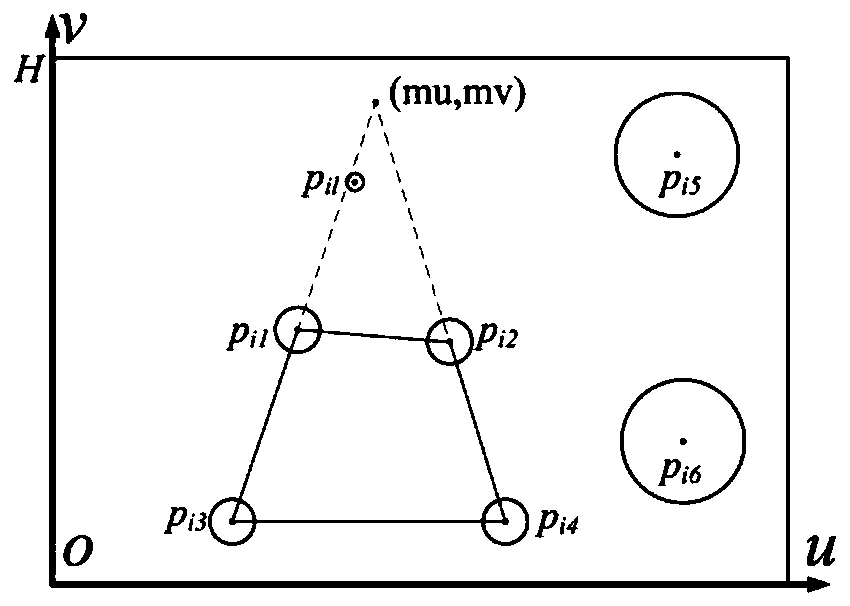

[0024] (1) A camera with a telecentric lens and a target plane are used to build a laser beam calibration device. The camera is facing the target plane. Two target spheres and four equal-diameter shadow circles are set on the target plane. There is no special requirement for their position distribution. It only needs to meet the line connecting the center of the shadow circle to form a square, and both the target ball and the shadow circle are within the field of view of the camera;

[0025] (2) Take the coordinate system of the three-coordinate measuring ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com