Method and device for measuring parameters of shape of laser differential confocal interference nuclear fusion pellet

A differential confocal and fusion target technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inconsistency of value reference, damage of target pills, and low efficiency, so as to improve the freedom of optical path design and reduce the The effect of adjustment accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

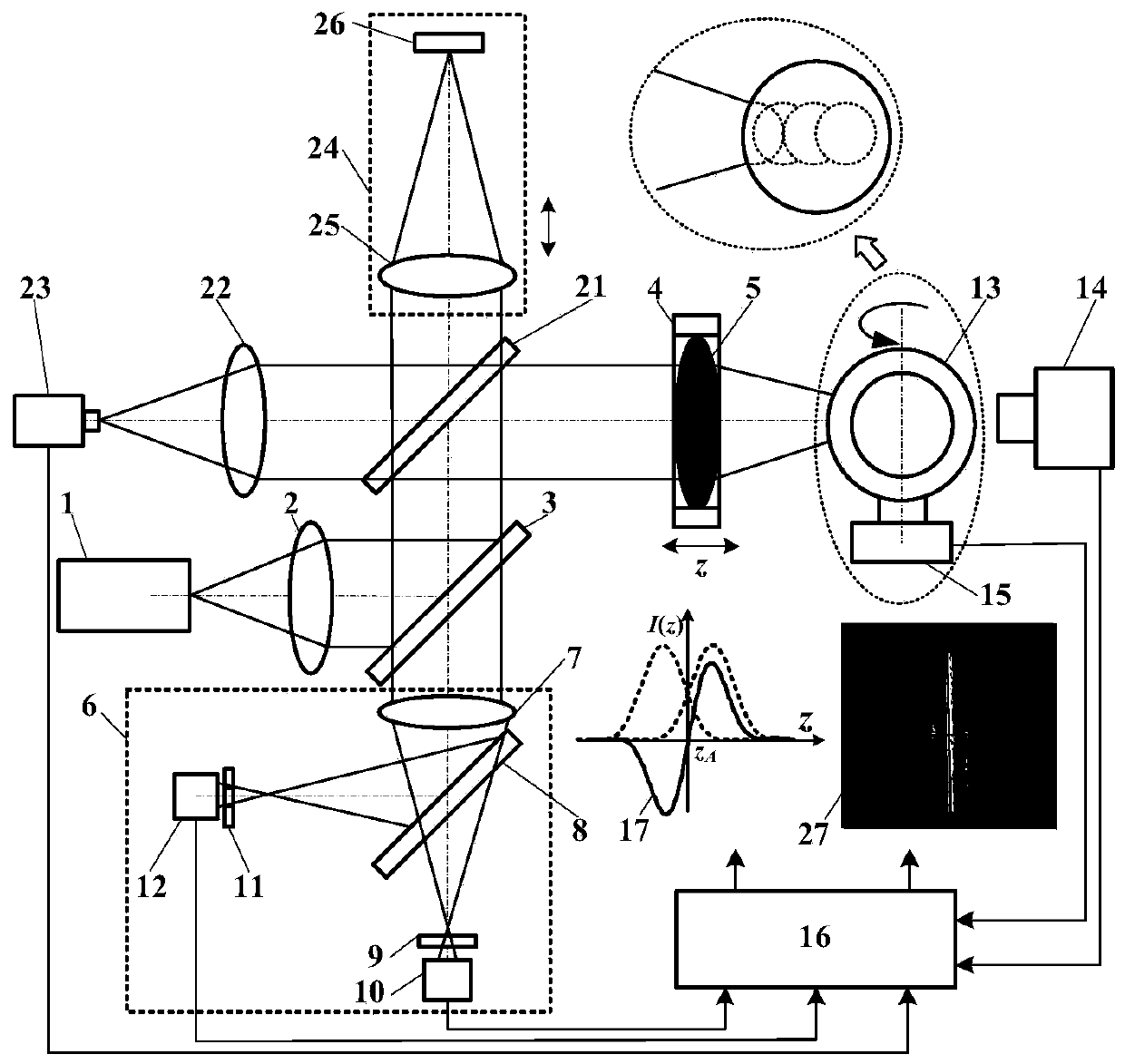

[0053] like image 3 As shown, in the comprehensive measurement method of laser differential confocal interference nuclear fusion nuclear fusion target shape and profile parameters, the light source system 1 uses a point light source, and the divergent light emitted by the point light source is collimated into a parallel beam by the collimator lens 2, and the parallel beam is split After being reflected by the mirror A3, it is divided into a transmitted illumination beam and a reflected illumination beam by the spectroscopic mirror C21, and the reflected illumination beam is converged into a point by the measurement objective lens 5 to illuminate the fusion target pellet 13 and be reflected. The reflected beam carrying the information of the fusion target pellet 13 passes through the measuring objective lens 5 to form a measuring beam, which is divided into a transmitted measuring beam and a reflected measuring beam by the beam splitter C21, and the reflected measuring beam ent...

Embodiment 2

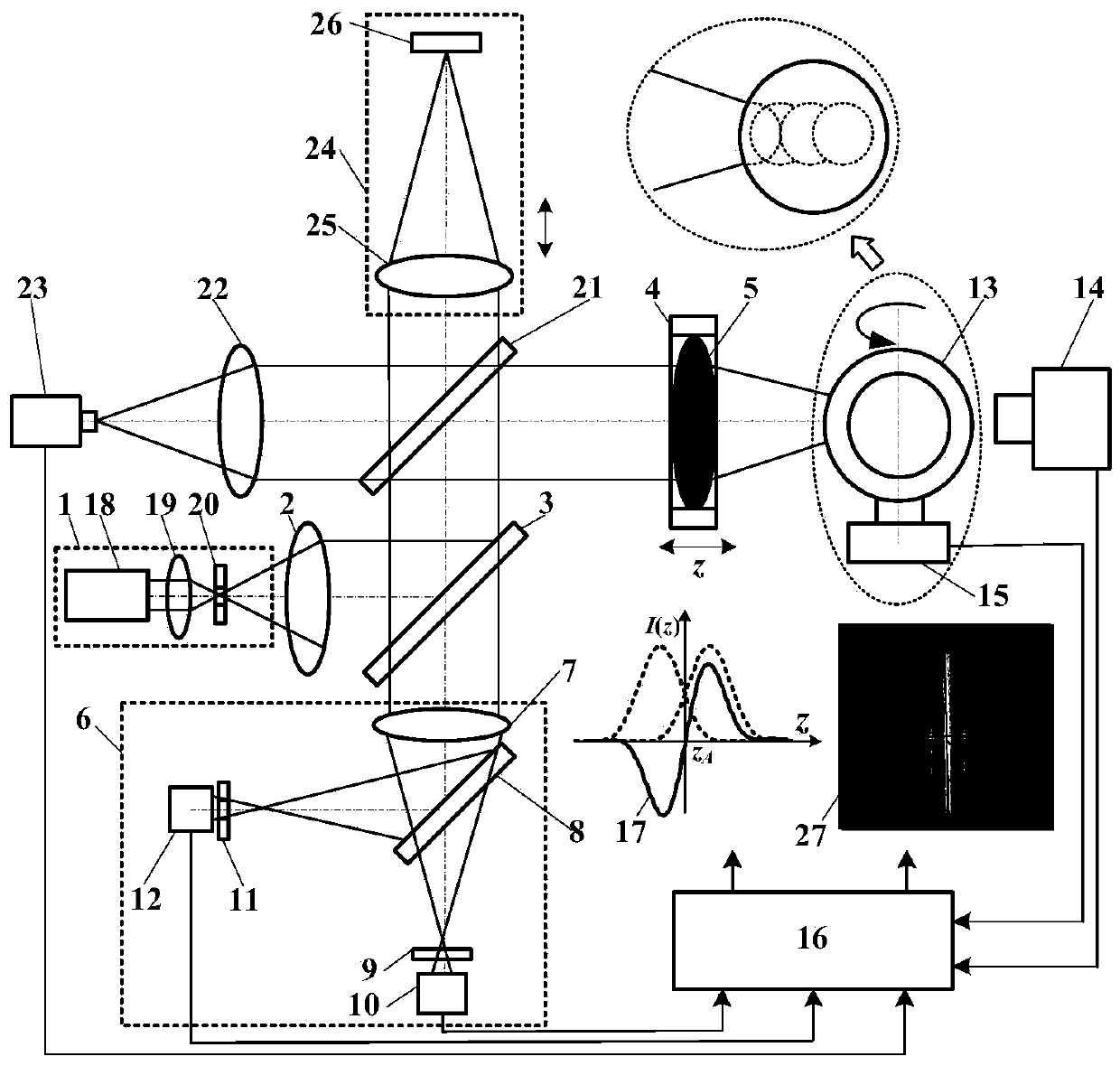

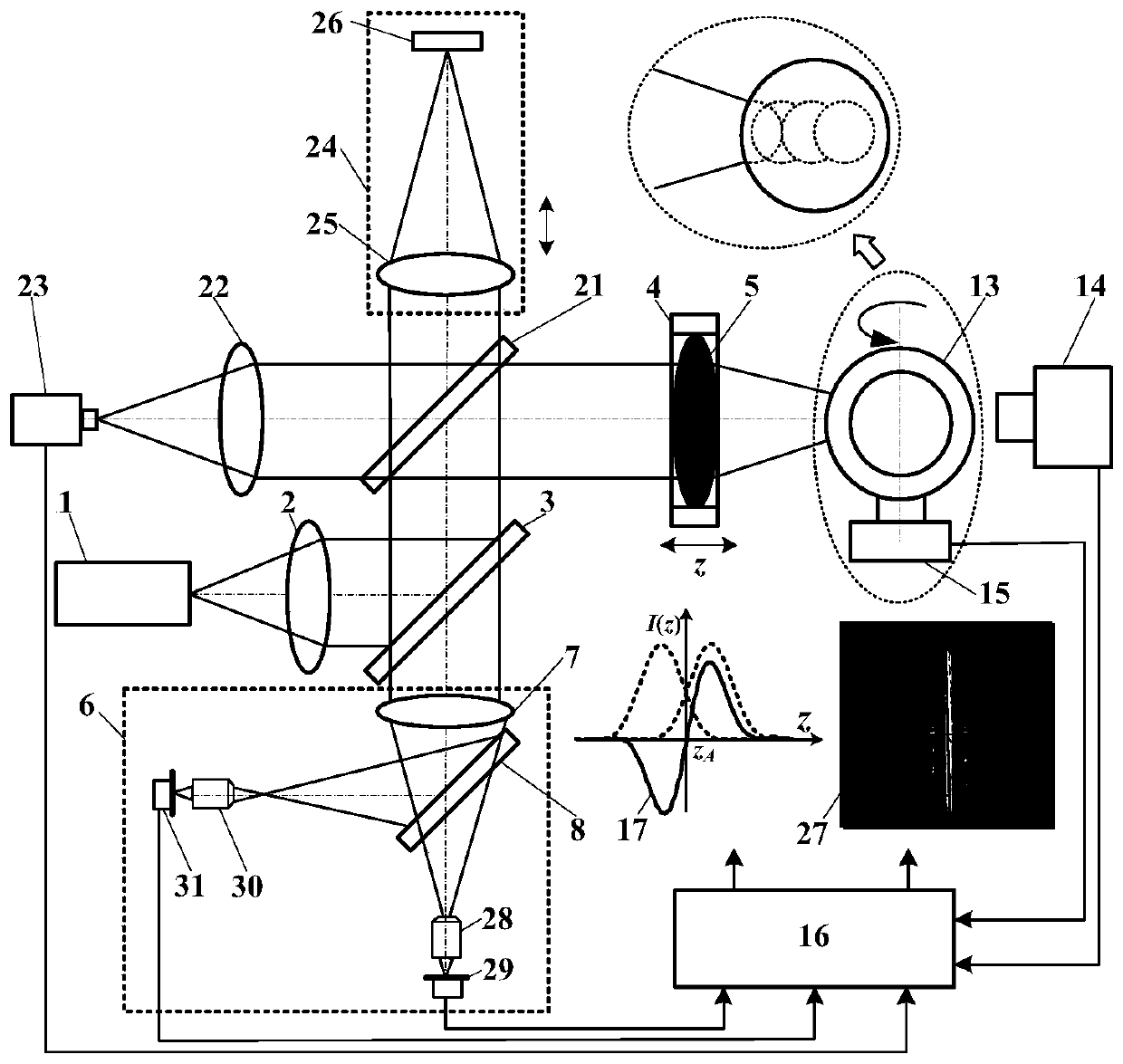

[0068] like Figure 4As shown, the comprehensive measurement device for the shape and profile parameters of the laser differential confocal interference nuclear fusion target capsule includes a light source system 1, a beam splitter A3 placed along the light source exit direction, and a beam splitter placed sequentially along the reflection direction of the beam splitter A3 C21 and interference arm 24, the measurement objective lens 5 placed sequentially along the reflection direction of the beam splitter C21, the differential confocal detection system 6 located in the opposite direction of the reflection direction of the beam splitter A3, and the imaging convergence located in the opposite direction of the reflection direction of the beam splitter C21 The mirror 22 and the interference CCD 23 are located in the outgoing direction of the measurement objective lens 5 and the orthogonal drive system 14 whose rotation axis is coaxial with the measurement optical axis, and the rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap