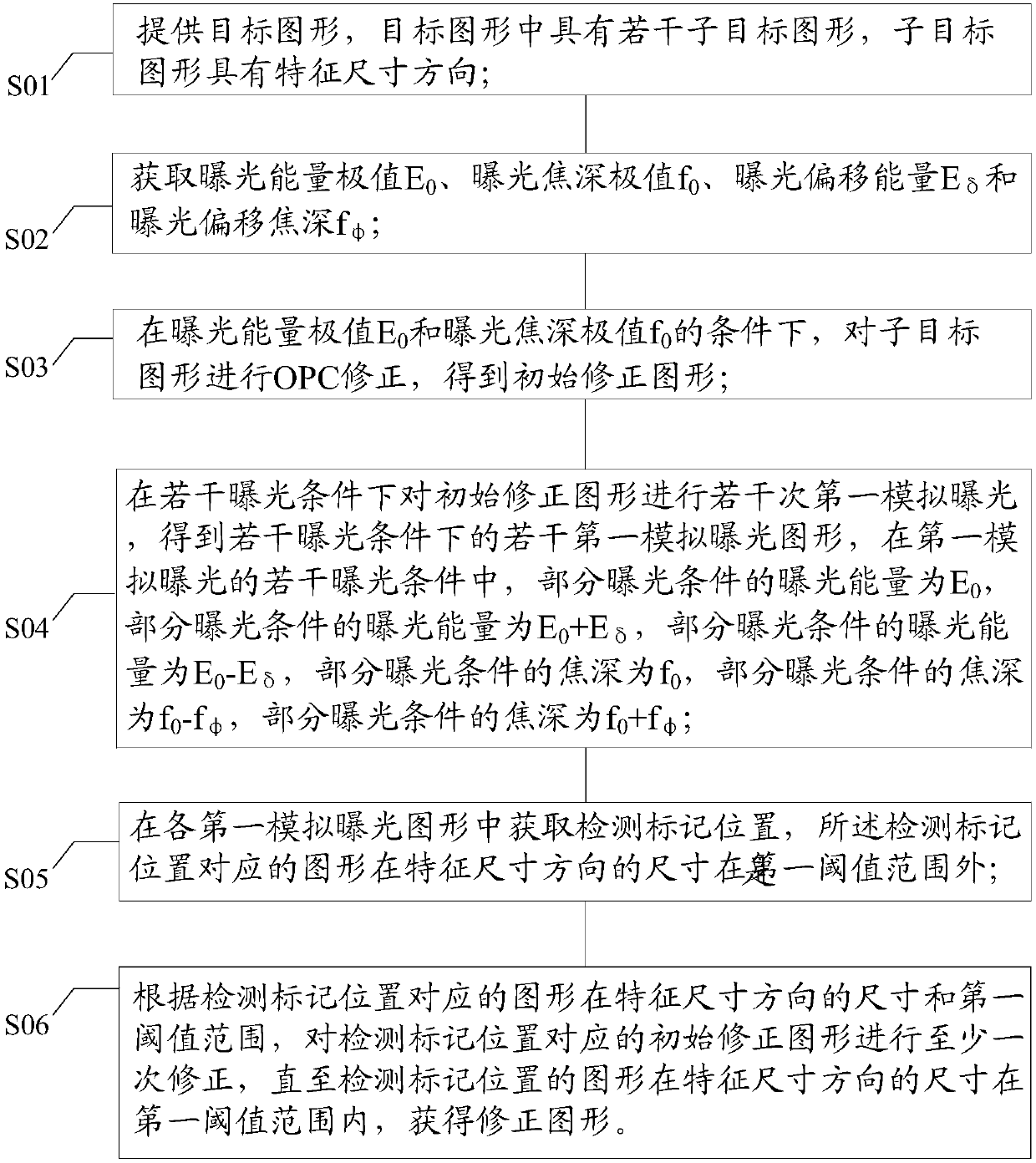

Optical proximity correction method and manufacturing method of mask plate

A technology of optical proximity correction and exposure conditions, which is applied in the direction of optics, originals for photomechanical processing, and photoplate-making process of patterned surface, etc., which can solve the problem of small process window and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As mentioned in the background, the process window of the graphics obtained by the existing optical proximity correction method is relatively small.

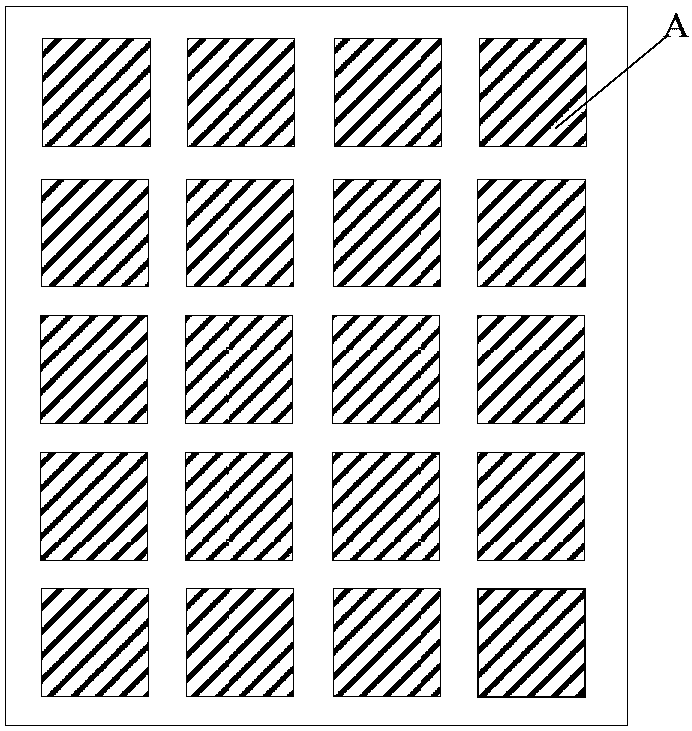

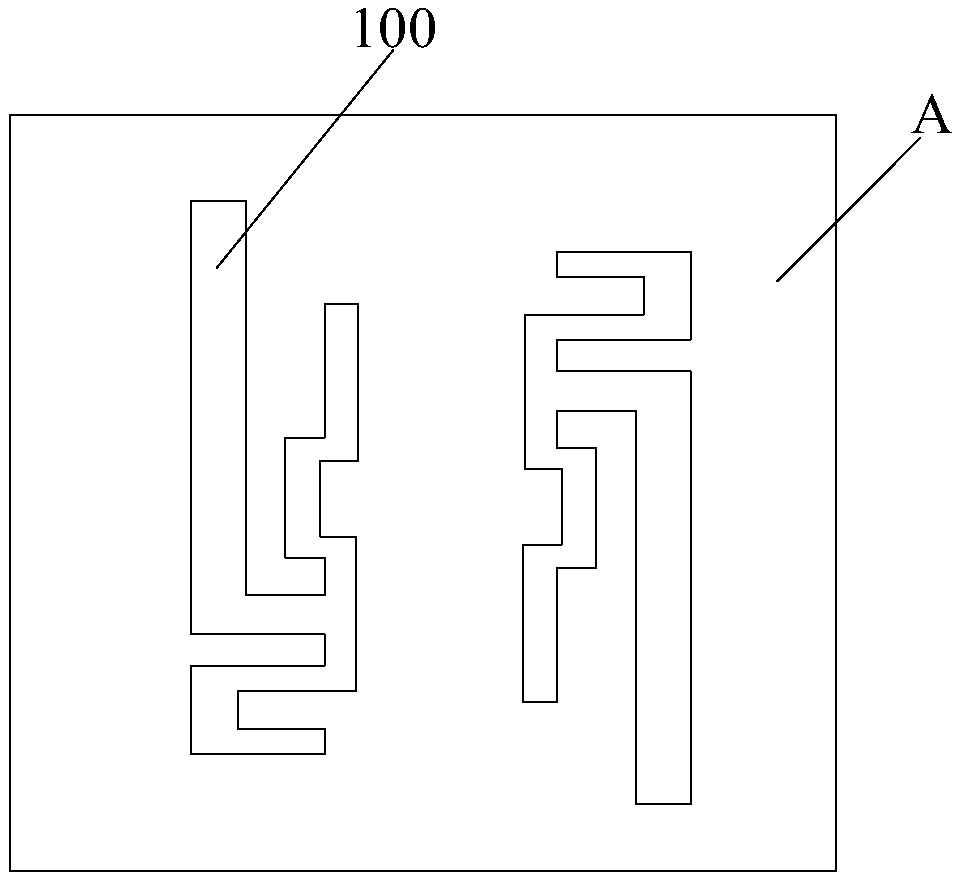

[0023] An optical proximity correction method, comprising: providing a target figure, in which there are several sub-target figures; setting the exposure energy extremum E 0 and exposure depth of focus extremum f 0 ;Provide OPC correction model; at the extreme value of exposure energy E0 and exposure depth of focus extremum f 0 Under the condition of , OPC correction is performed on the sub-object figure according to the OPC correction model to obtain a corrected figure, and the edge placement error of the corrected figure is less than or equal to the first threshold.

[0024] After the corrected figure is obtained, it is usually necessary to perform OPC detection on the corrected figure to obtain the position of the detection mark, which is usually called a weak point. Specifically, the simulated exposure is performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com