Anti-skid shoe sole and production technology of anti-skid pad

A technology of anti-slip pads and soles, which is applied in the direction of soles, footwear, footwear, etc., can solve the problems of time-consuming and labor-intensive replacement of shoes, and achieve the effects of convenient disassembly, excellent anti-slip performance, and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

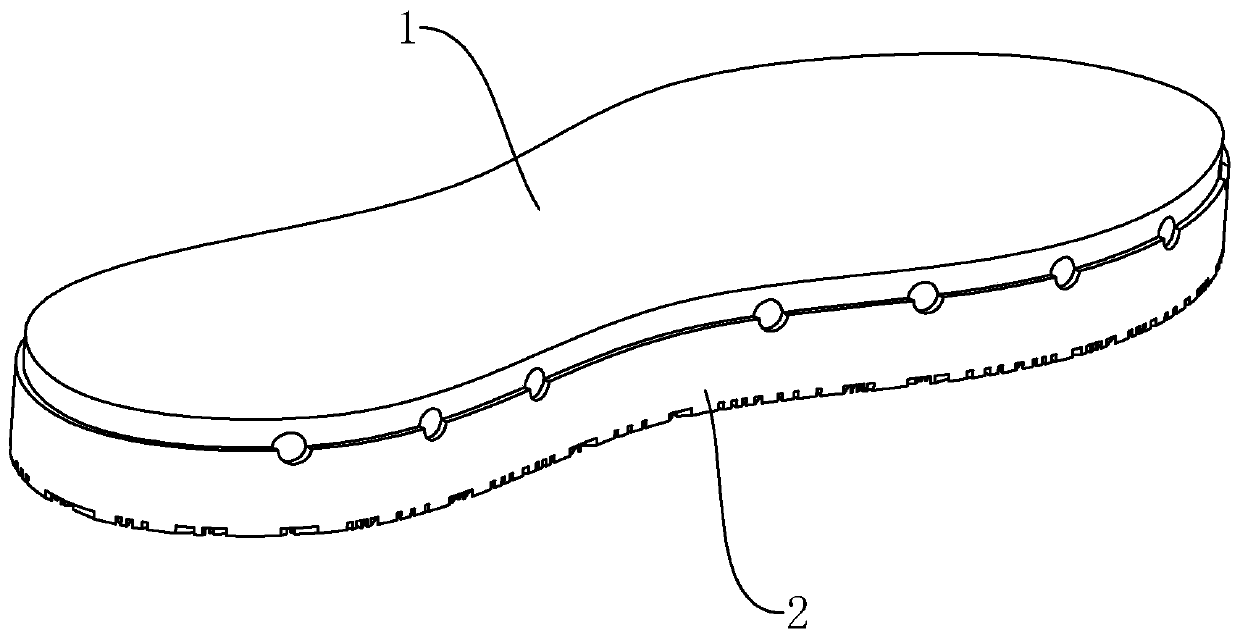

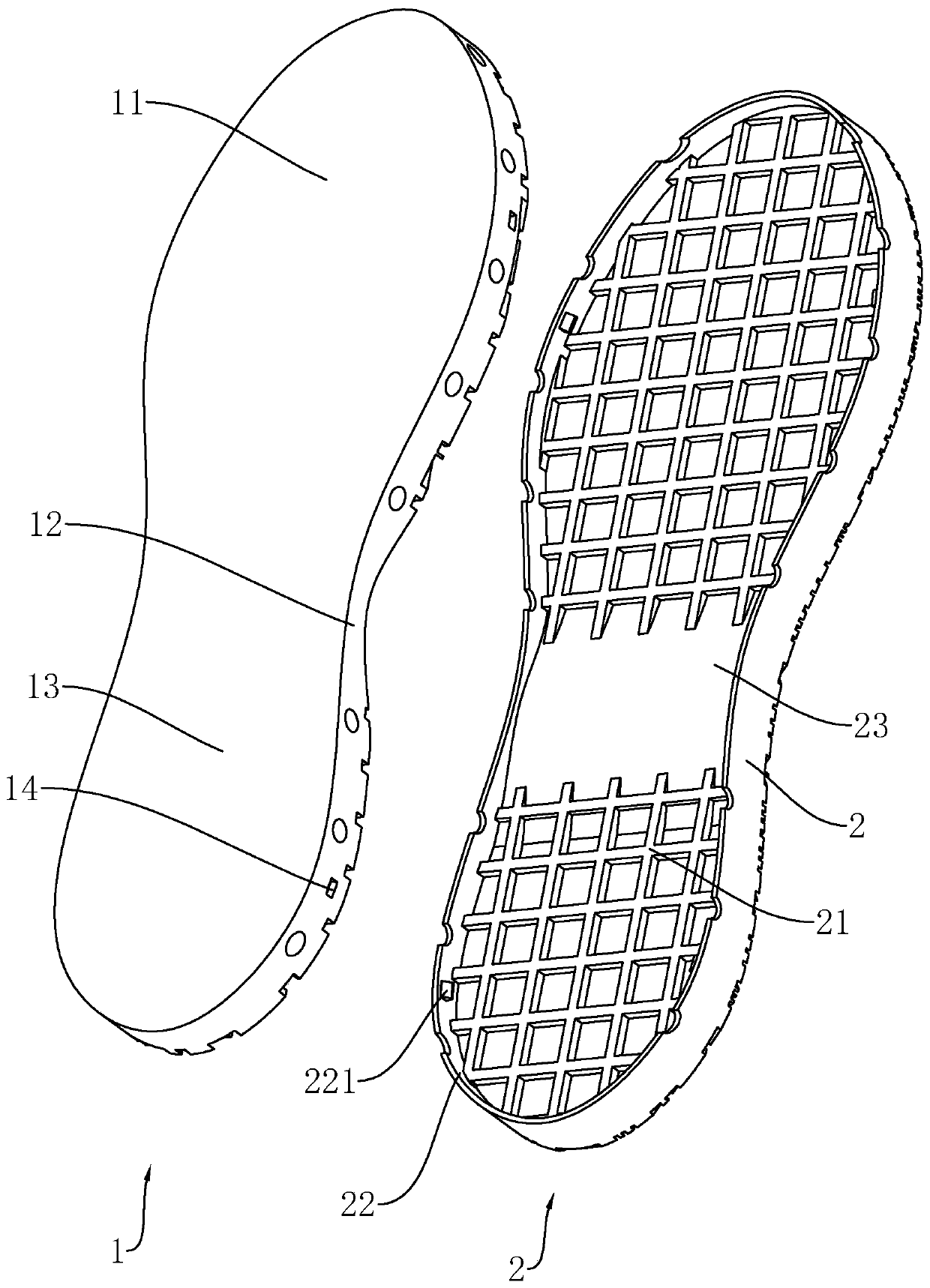

[0053] A non-slip sole such as figure 1 As shown, it includes a sole base 1 and an anti-skid pad 2 detachably mounted on the bottom of the sole base 1 . The sole matrix 1 is made of a material with better performance such as air permeability, cushioning or wear resistance, and the anti-skid pad 2 is made of a material with better anti-skid performance. When the anti-slip pad 2 is installed on the bottom of the sole base 1, it can have a better anti-slip effect, avoiding the danger of the user falling in an environment prone to slipping; after the anti-slip pad 2 is removed, the wearing comfort of the user is improved, and the anti-slip pad can be avoided. 2 Trouble with too fast wear.

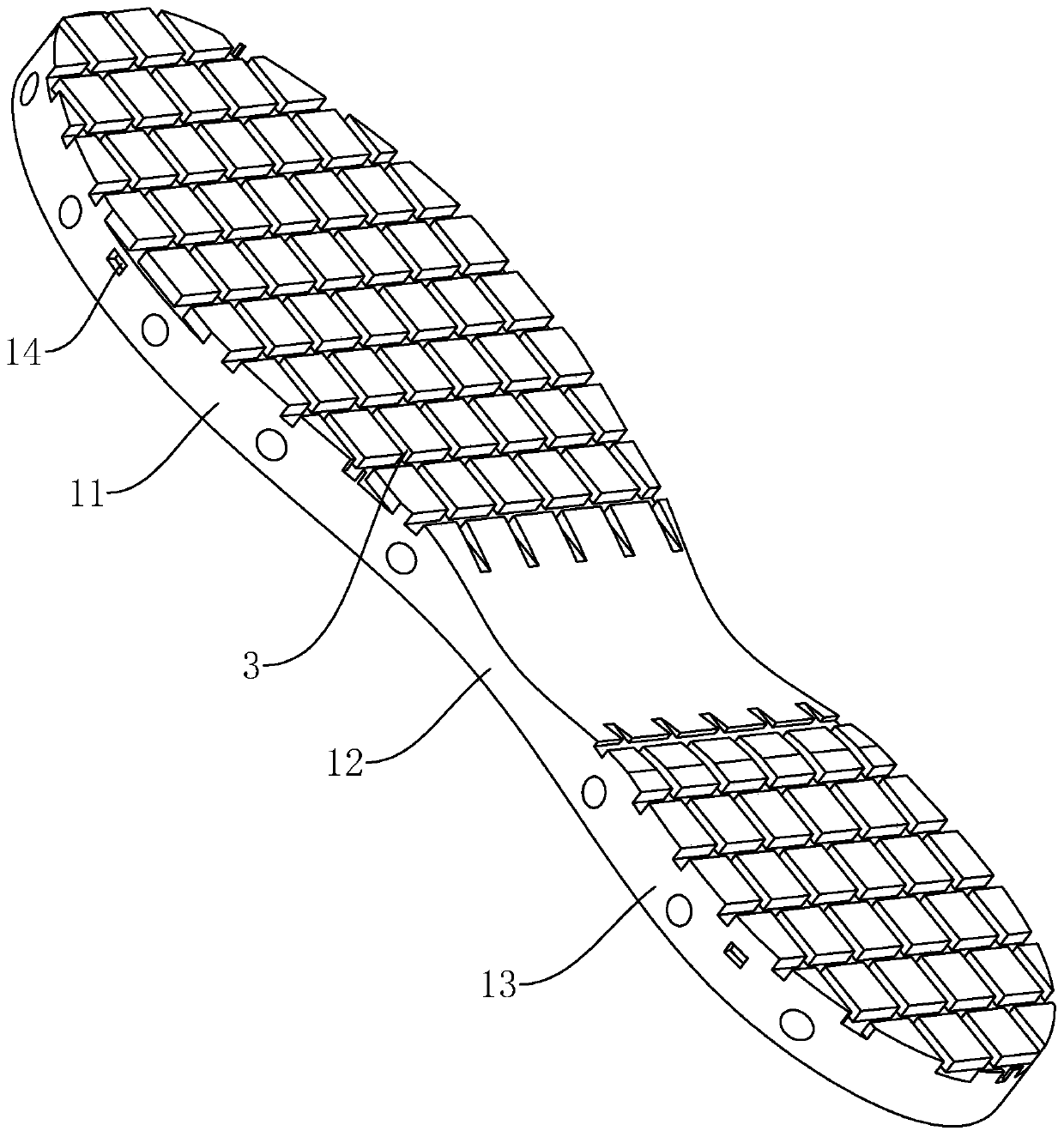

[0054] Such as figure 2 , image 3As shown, the sole matrix 1 is divided into a forefoot portion 11, an arch portion 12, and a heel portion 13 successively along its length direction, and the forefoot portion 11 and the heel portion 13 are provided with grid-shaped anti-slip grooves 3, so t...

Embodiment 2

[0060] The anti-skid mat in embodiment one comprises the following components by weight:

[0061] 30 parts of methyl vinyl silicone rubber;

[0062] 35 parts of nitrile rubber;

[0063] Bromobutyl rubber 20 parts;

[0064] 4 parts of compatibilizer;

[0065] 30 parts of transparent white carbon black;

[0066] Polyethylene glycol-4000 2 parts;

[0067] Active zinc oxide 2 parts;

[0068] 0.4 parts of stearic acid;

[0069] Rosin 0.8 parts;

[0070] 1.6 parts of vulcanizing agent, the vulcanizing agent is compounded by equal mass ratio of sulfur and DCP;

[0071] Accelerator 1 part, the accelerator is compounded by accelerator DM, accelerator H and accelerator PX in equal mass ratio;

[0072] 0.3 parts of anti-aging agent, the anti-aging agent is compounded by anti-aging agent 264 and anti-aging agent RD in equal mass ratio;

[0073] 4 parts of hydroxyl silicone oil;

[0074] 0.4 parts of diphenylsilanediol.

[0075] The preparation process of the compatibilizer is a...

Embodiment 3

[0083] The anti-skid mat in embodiment one comprises the following components by weight:

[0084] 35 parts of methyl vinyl silicone rubber;

[0085] 40 parts of nitrile rubber;

[0086] Bromobutyl rubber 25 parts;

[0087] 6 parts of compatibilizer;

[0088] 40 parts of transparent white carbon black;

[0089] Polyethylene glycol-4000 3 parts;

[0090] Active zinc oxide 3 parts;

[0091] 0.6 parts of stearic acid;

[0092] Rosin 1.2 parts;

[0093] 2 parts of vulcanizing agent, the vulcanizing agent is compounded by equal mass ratio of sulfur and DCP;

[0094] Accelerator 2 parts, the accelerator is compounded by accelerator DM, accelerator H and accelerator PX in equal mass ratio;

[0095] 0.6 parts of anti-aging agent, the anti-aging agent is compounded by anti-aging agent 264 and anti-aging agent RD in equal mass ratio;

[0096] 6 parts of hydroxyl silicone oil;

[0097] 0.8 parts of diphenylsilanediol.

[0098] The preparation process of the compatibilizer is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abrasion | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap