Polyurethane functional insole

A polyurethane and polyurethane layer technology, applied in the field of polyurethane functional insoles and insoles, can solve the problems of high product sales price, high cost of natural latex, unfavorable product promotion, etc., achieve good far-infrared characteristics, activate the function of the reticuloendothelial system, accelerate The effect of blood flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

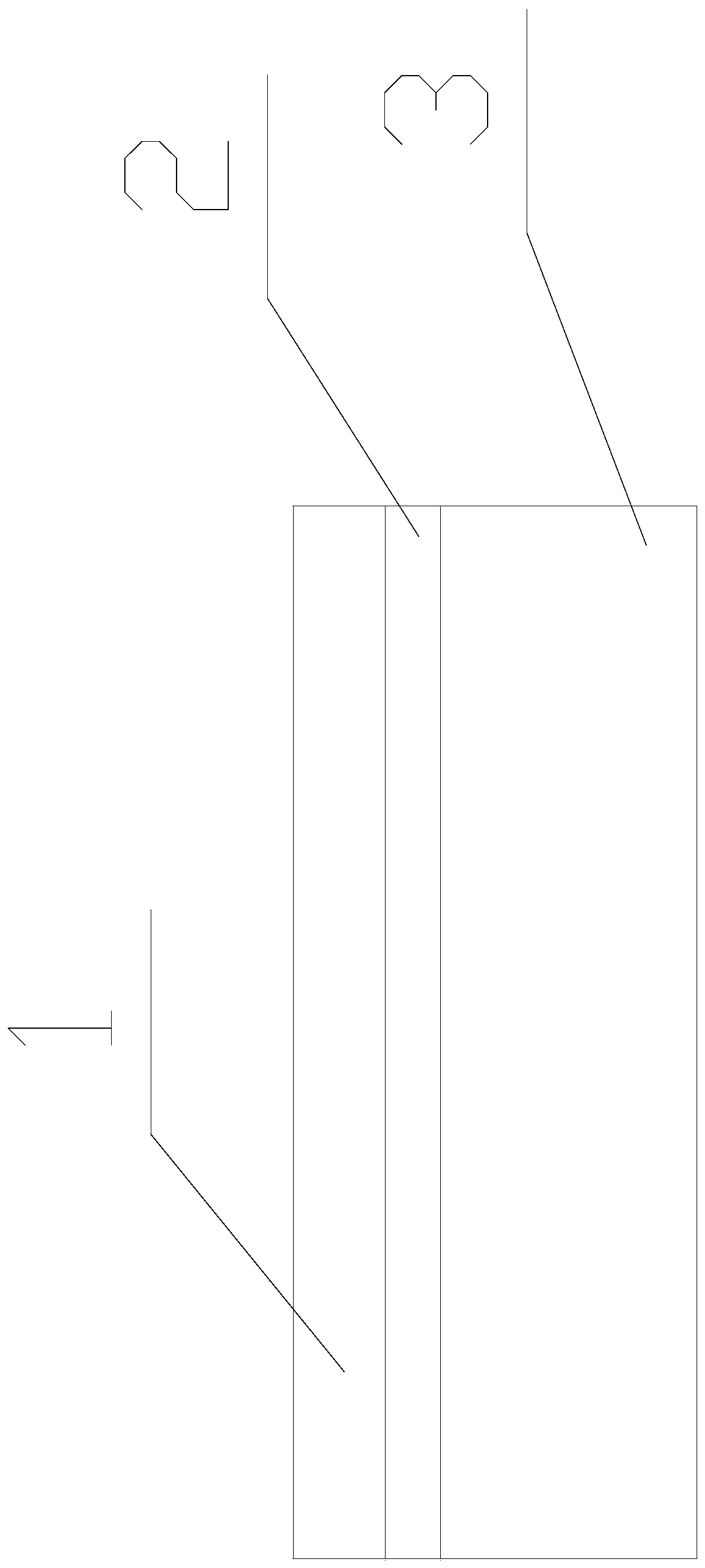

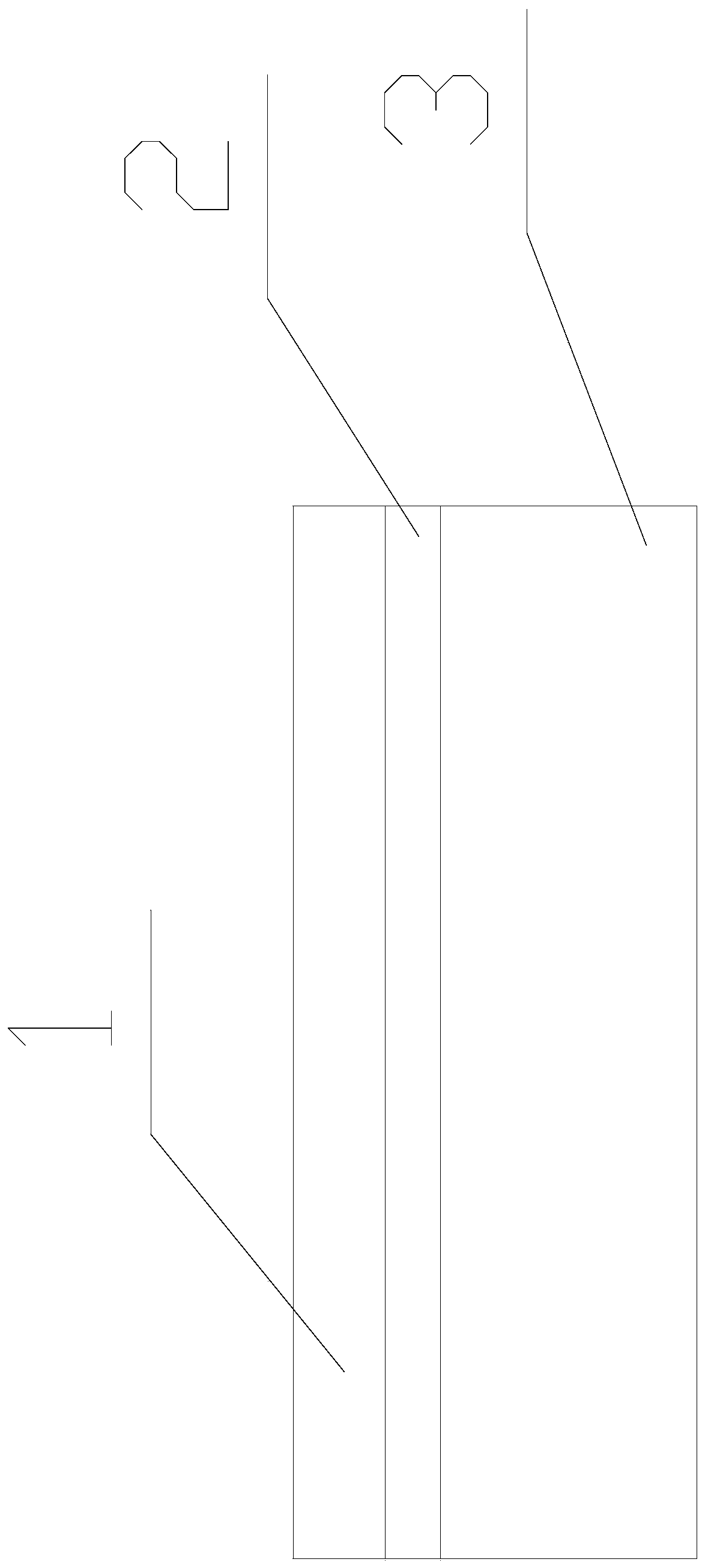

Image

Examples

Embodiment

[0028] Embodiment: A kind of polyurethane functional insole, comprises artificial leather layer, adhesive layer and polyurethane layer, polyurethane layer and artificial leather layer are combined together by adhesive layer; Adhesive layer is made up of polyurethane glue and functional powder, polyurethane The percentage of the glue component is 75%, the percentage of the functional powder component is 25%; the functional powder is composed of the following components with a particle size less than 7000 mesh and the percentage of each component is tourmaline: 12%, magnet: 10%, jade: 10%, far-infrared ceramic composite powder: 12%, bamboo charcoal: 6%, crystal: 6%, talc: 20%, antibacterial powder: 24%.

[0029] Further, the production process of polyurethane functional insole is as follows:

[0030] (4) the artificial leather layer is first cut into a rectangle of corresponding size, then spray adhesive on the back side of the artificial leather layer, the spraying ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com