Creeping mode pump displacement control method based on optimal overall efficiency

A technology of comprehensive efficiency and control method, applied in the field of peristaltic mode pump displacement control based on optimal comprehensive efficiency, to achieve real control effect, reduce response difference characteristics, and solid and reliable theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in detail below in conjunction with accompanying drawing:

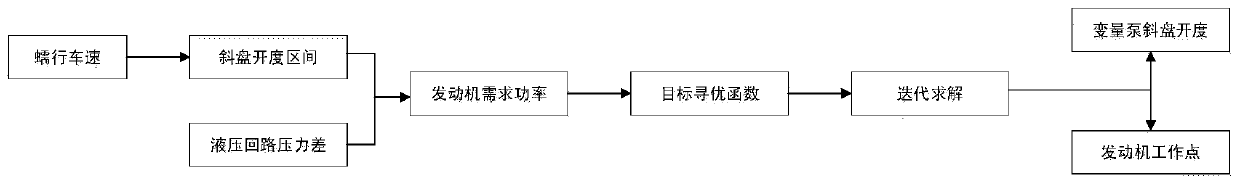

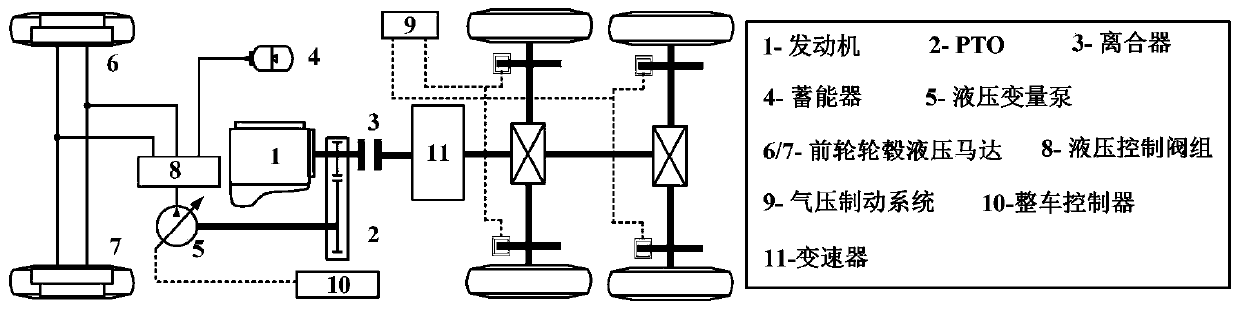

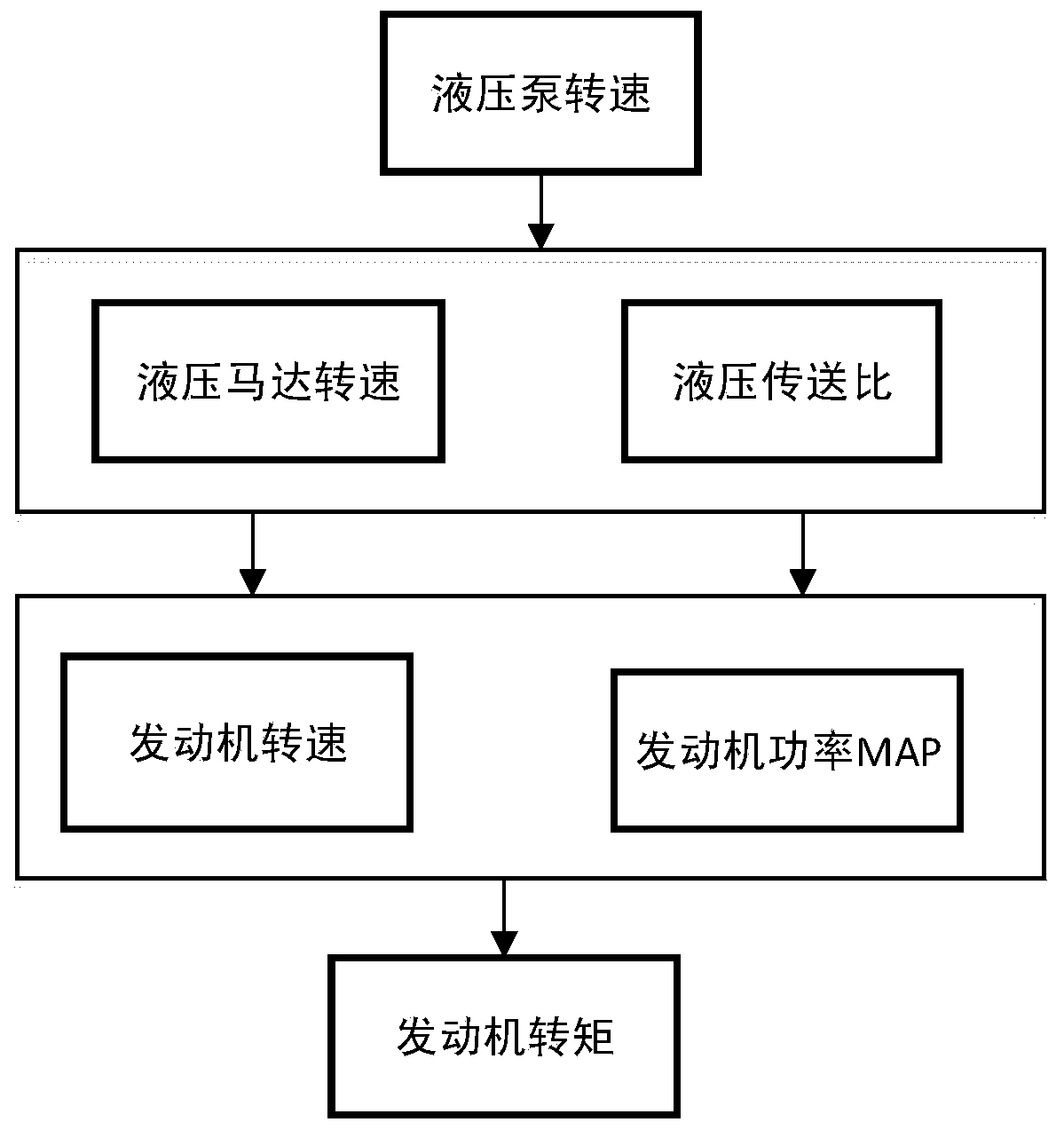

[0058] refer to figure 1 , the hub hydraulic creeping mode pump displacement control method described in the present invention is divided into five steps: Step 1 is to determine the pump swash plate opening search interval, based on any permissible creeping speed, after determining the current wheel position After the required power, wheel hub hydraulic motor speed and closed-loop hydraulic pressure difference, the search range of variable pump swashplate opening can be further determined; Step 2 is to determine the engine demand power corresponding to the pump swashplate opening, combined with the current closed-loop hydraulic pressure difference and related volumetric efficiency of the engine and variable pump to obtain the required power of the engine under the corresponding pump swashplate opening; step 3 is to determine the engine operating point, based on the current hub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com