Deep treatment technology and device for non-biodegradable wastewater

A technology of advanced treatment and biochemical treatment, applied in biological water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of large chemical sludge, mediocre effect, high cost, etc., and achieve Improve the biodegradability, rapid response, and reduce the effect of oxygenation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The COD of the effluent after biochemical treatment in a centralized sewage treatment plant in a chemical industry park is as high as 200-300mg / L (BOD is less than 5 mg / L, which is not biodegradable), and the following treatment is carried out:

[0018] Step 1: Ozone ultrasonic synergistic oxidation treatment: non-biodegradable wastewater flows into the water inlet of the gas dissolver, and the ozone gas generated by the ozone generator enters the wastewater to be treated through the ozone inlet hole of the gas dissolver, and is fully mixed with the wastewater. Control the proportional relationship between the dosage of ozone and the amount of COD required to degrade, referred to as the O / C ratio, to control the dosage of ozone, and the O / C ratio is controlled at 2mgO 3 / mgCOD; then the wastewater dissolved with ozone gas is discharged from the diffusion section of the gas dissolver and enters the ultrasonic reactor (liquid whistle or reed ultrasonic generator), under th...

Embodiment 2

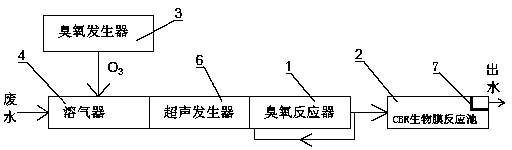

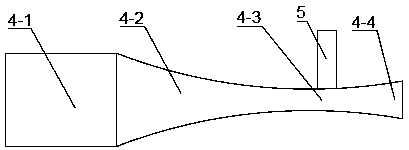

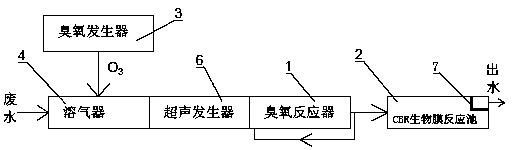

[0022] Such as figure 1 As shown, the advanced treatment device of a kind of biodegradable wastewater described in this embodiment includes an ozone reactor 1, an air dissolver 4, an ultrasonic generator 6 and a CBR biofilm reaction tank 2, and the air dissolver 4 and Ozone generator 3, water inlet pump, ultrasonic generator 6 are connected, and ultrasonic generator 6 is connected with ozone reactor 1, as figure 2 As shown, the gas dissolver 4 includes an inlet section 4-1, a contraction section 4-2, a throat 4-3 and a diffusion section 4-4, and an ozone inlet hole is provided at the throat 4-3 of the gas dissolver 4 5. The ozone inlet hole 5 is connected to the ozone generator 3; the inlet of the inlet section 4-1 of the gas dissolver 4 is connected to the water inlet pump, and the outlet of the diffuser section 4-4 of the gas dissolver 4 is connected to the liquid whistle ultrasonic generator 6 connection; the water outlet end of the ozone reactor 1 is connected with the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com