Construction method of fully-prefabricated assembled permeable road

A prefabricated assembly and construction method technology, applied in the direction of roads, roads, soil protection, etc., can solve the problems of large environmental impact of cast-in-place roads, difficult drainage of cast-in-place structures, low bearing capacity of roadbed, etc., to meet load-bearing requirements and durability High performance requirements, easy operation of the construction process, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

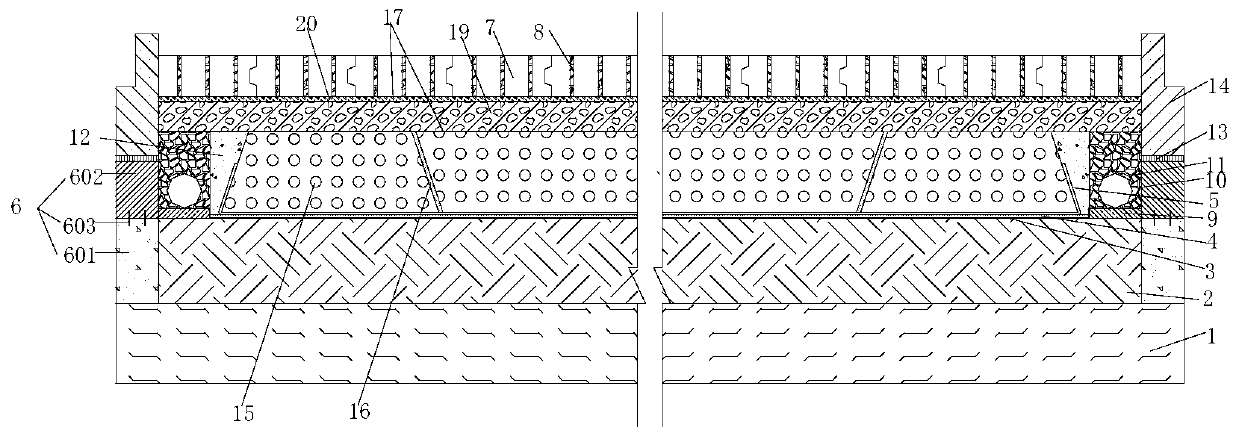

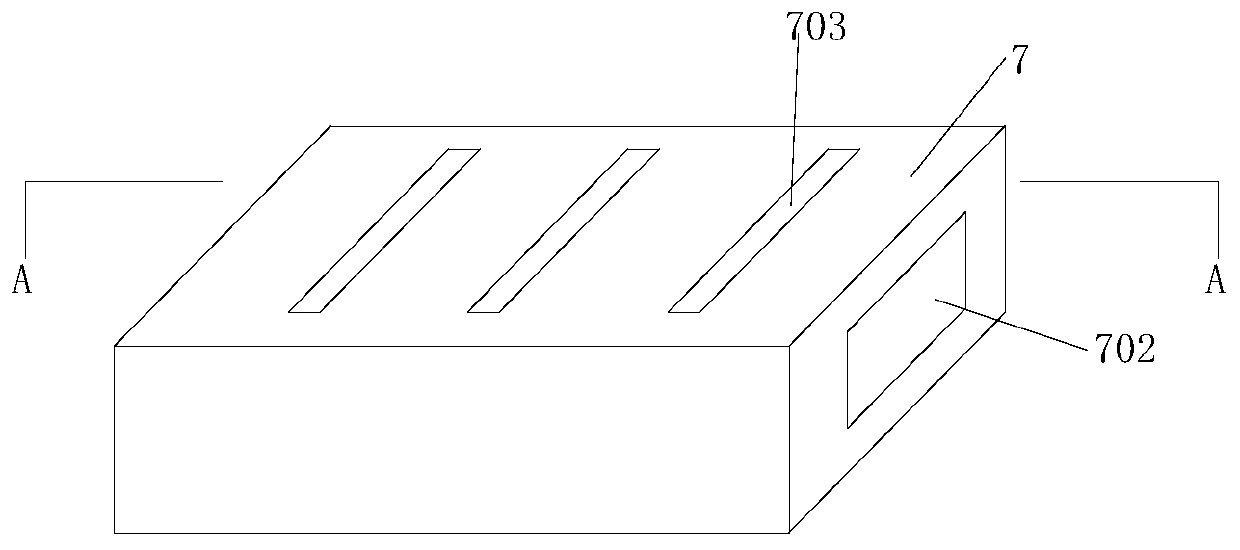

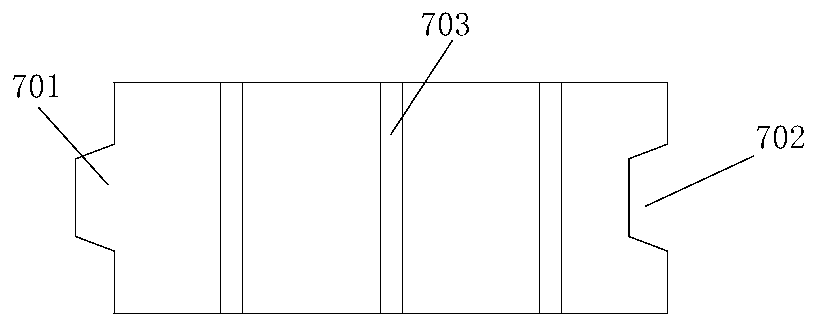

[0052] combined with figure 1 As shown, the present invention relates to a fully prefabricated assembled permeable road, including a subgrade 1, a subbase 2, a porous brick layer, a gravel drainage base 19 and a pavement structure layer.

[0053] The two sides of the roadbed 1 are provided with a stop body 6 and a curb 14 from bottom to top. The stop body 6 includes a lower stop body 601 and an upper stop body 602, and a connecting rib 603 is passed between the lower stop body 601 and the upper stop body 602. To connect with each other, the connecting bars 603 are steel bars with a diameter of 12 mm and a length of 40 cm; the retaining body 6 and the curb 14 are bonded by a mortar cushion 13 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com