Photoinduced-deformation intelligent electrode and electrochemical machining method thereof

A technology of electrochemical machining and photodeformation, which is applied in the field of electrodes, can solve the problems of low machining accuracy, surface quality electrode damage, rapid decline, etc., and achieve the effect of good surface quality and reduced molding processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

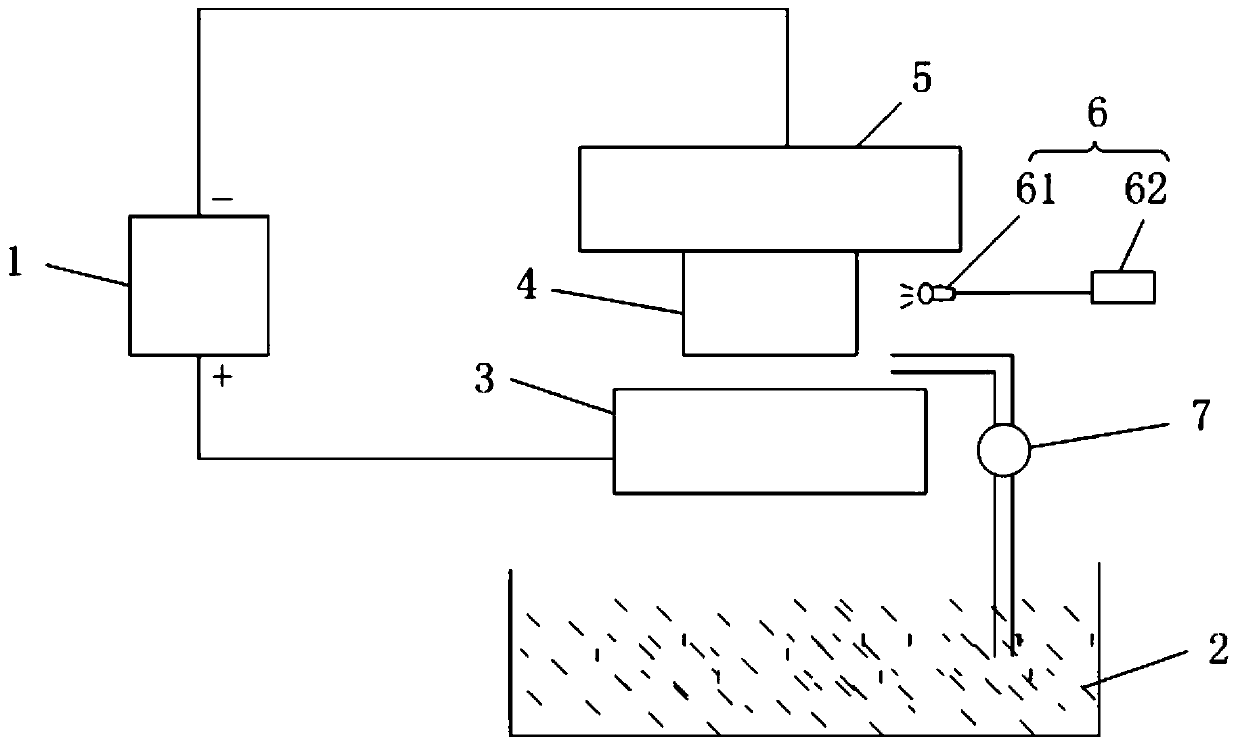

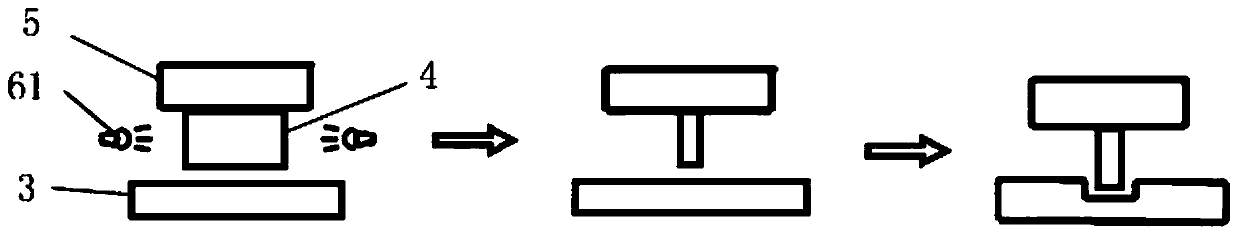

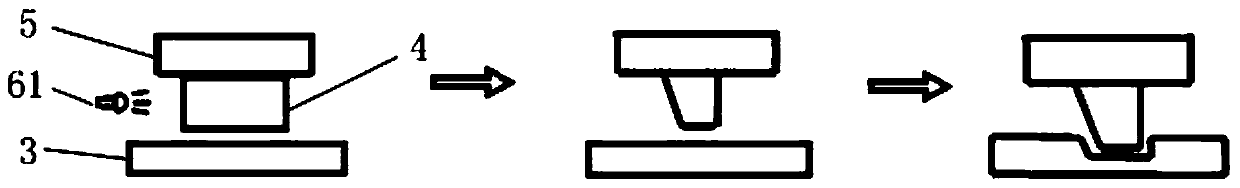

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The invention provides a photodeformable smart electrode, which is made of conductive photodeformable material.

[0036] The photodeformable smart electrode of the present invention has two characteristics, electrical conductivity and photodeformation characteristics. Since the photodeformable material contains a color-changing group, after the material absorbs light, molecular isomerization will occur, causing changes in the overall size and shape of the material. The present invention uses conductive photodeformable materials to make electrodes, and by adjusting parameters such as the wavelength of light, light mode, light intensity, and light time, the electrodes can be made to produce photoshrinkage, photobending, or photoinduced volumetric deformation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com