Acid-free paper board manufacturing method

A production method and technology of acid-free paper, which are applied in chemical instruments and methods, paper/cardboard layered products, mechanical processing/deformation, etc. Folding and other problems, to achieve the effect of good protection of cultural relics, prevention of water vapor penetration, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

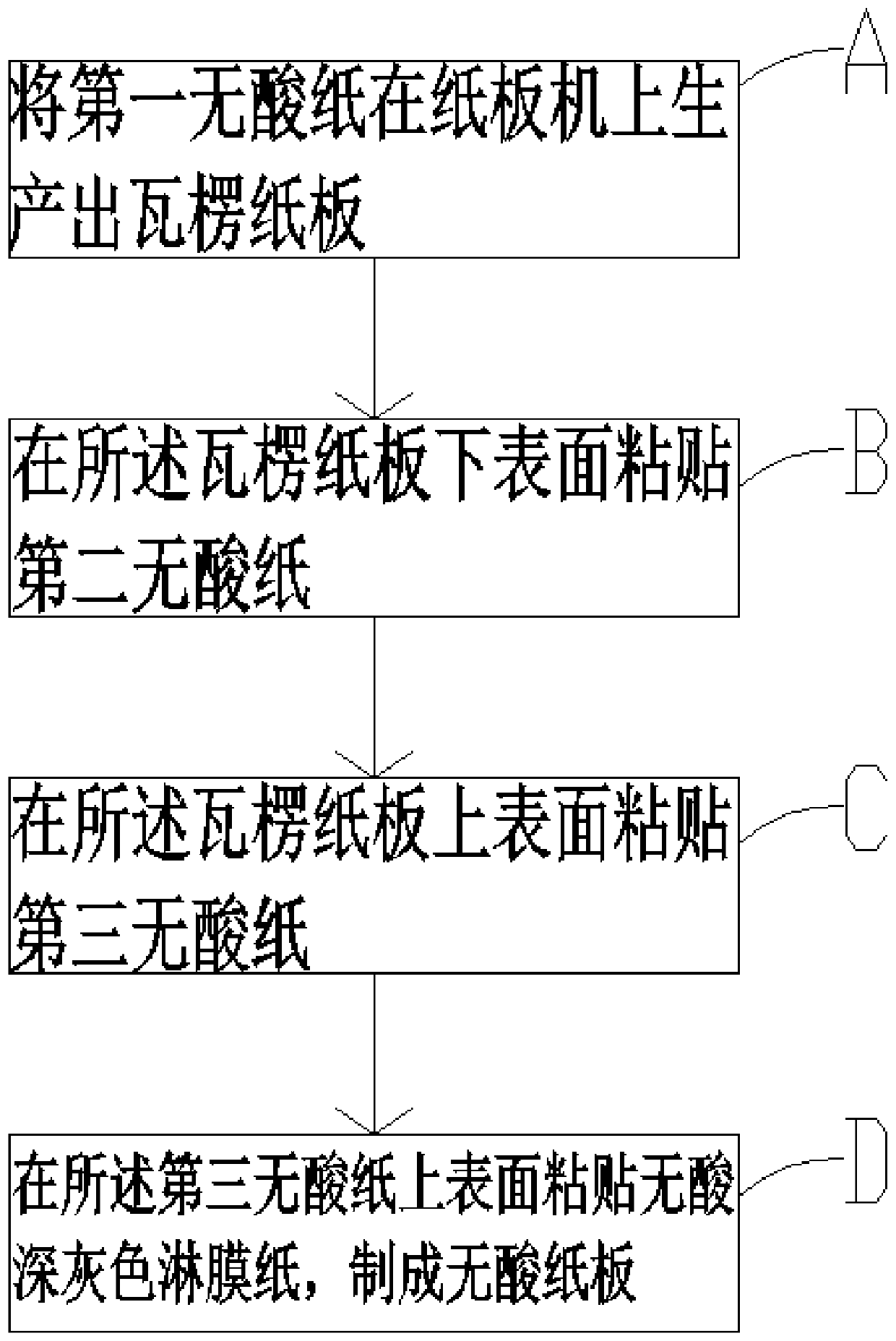

[0017] figure 1 It is a flowchart of a method for making acid-free cardboard provided by the invention. The method for making acid-free cardboard of the present invention mainly includes the following four steps, wherein step A is to firstly put the first acid-free paper into the cardboard machine to produce corrugated cardboard, the first acid-free paper has a square structure and is thinner in thickness, When the first acid-free paper is put into the cardboard machine, the first acid-free paper can be made into corrugated cardboard in a corrugated shape, and the first acid-free paper can be made into corrugated cardboard to make the acid-free cardboard have better Bursting resistance and folding resistance, the second step is step B, step B is to paste the second acid-free paper under the corrugated cardboard, the longitudinal section diameter of the second acid-free paper is the same as the longitudinal section diameter of the corrugated cardboard, the first The longitudin...

Embodiment 2

[0021] figure 1 It is a flowchart of a method for making acid-free cardboard provided by the invention. The method for making acid-free cardboard of the present invention mainly includes the following four steps, wherein step A is to firstly put the first acid-free paper into the cardboard machine to produce corrugated cardboard, the first acid-free paper has a square structure and is thinner in thickness, When the first acid-free paper is put into the cardboard machine, the first acid-free paper can be made into corrugated cardboard in a corrugated shape, and the first acid-free paper can be made into corrugated cardboard to make the acid-free cardboard have better Bursting resistance and folding resistance, the second step is step B, step B is to paste the second acid-free paper under the corrugated cardboard, the longitudinal section diameter of the second acid-free paper is the same as the longitudinal section diameter of the corrugated cardboard, the first The longitudin...

Embodiment 3

[0026] figure 1It is a flowchart of a method for making acid-free cardboard provided by the invention. The method for making acid-free cardboard of the present invention mainly includes the following four steps, wherein step A is to firstly put the first acid-free paper into the cardboard machine to produce corrugated cardboard, the first acid-free paper has a square structure and is thinner in thickness, When the first acid-free paper is put into the cardboard machine, the first acid-free paper can be made into corrugated cardboard in a corrugated shape, and the first acid-free paper can be made into corrugated cardboard to make the acid-free cardboard have better Bursting resistance and folding resistance, the second step is step B, step B is to paste the second acid-free paper under the corrugated cardboard, the longitudinal section diameter of the second acid-free paper is the same as the longitudinal section diameter of the corrugated cardboard, the first The longitudina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com