Method for preparing planting brick by coal gangues and planting brick structure

A technology for planting bricks and gangue, which is applied to botany equipment and methods, pavements paved with prefabricated blocks, planting substrates, etc., can solve the problems of not realizing the effective combination of gangue and planting bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

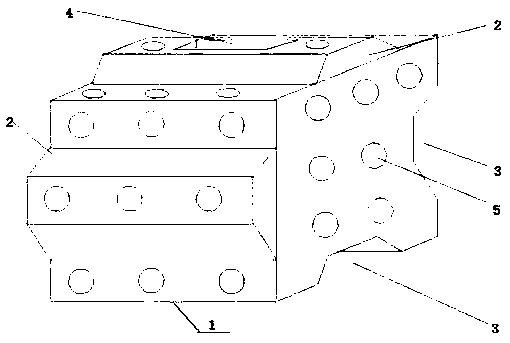

[0019] Example 1. As figure 1 Shown, a kind of method that utilizes coal gangue to prepare planting brick and the structure of planting brick,

Embodiment 1

[0021] The preparation method of described planting brick comprises:

[0022] S1, putting coal gangue into stone crushing equipment for processing to obtain stone powder;

[0023] S2. Add 50 parts by weight of kitchen waste, 15 parts by weight of potassium nitrate, 15 parts by weight of calcium chloride, 20 parts by weight of magnesium sulfate and 18 parts by weight of iron salt to 150 parts by weight of the stone powder. After uniformity, the mixture is obtained;

[0024] S3. Spread the mixed material indoors into a stone pile with a height of 15 cm, and irradiate it with an ultraviolet lamp with a frequency of 200 nm for 20 min;

[0025] S4. Spray 25 parts by weight of mixed bacteria liquid and 55 parts by weight of water into the stone pile after ultraviolet lamp irradiation to obtain a mixture. After placing the mixture at 50°C for 4 days, add 30 parts by weight of a mass fraction of 10 % lemonade, then placed at 65°C for 2 days, and finally at 35°C for 5 days to obtain ...

Embodiment 2

[0028] The preparation method of planting brick comprises:

[0029] S1, putting coal gangue into stone crushing equipment for processing to obtain stone powder;

[0030] S2. Add 85 parts by weight of kitchen waste, 30 parts by weight of potassium nitrate, 25 parts by weight of calcium chloride, 30 parts by weight of magnesium sulfate and 25 parts by weight of iron salt to 200 parts by weight of the stone powder. After uniformity, the mixture is obtained;

[0031] S3. Spread the mixed material indoors into a stone pile with a height of 25 cm, and irradiate it with an ultraviolet lamp with a frequency of 400 nm for 30 min;

[0032] S4. Spray 35 parts by weight of mixed bacteria liquid and 85 parts by weight of water into the stone pile after ultraviolet lamp irradiation to obtain a mixture, place the mixture at 60°C for 6 days, add 45 parts by weight of 20% by mass Lemonade, then placed at 75°C for 3 days, and finally at 45°C for 7 days to obtain a fermented product;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com