Premixed permeable concrete matching ratio design and preparation method thereof

A technology of permeable concrete and mix ratio design, which is applied in the field of ready-mixed permeable concrete for construction. It can solve the problems of dust pollution, noise pollution and low production efficiency in the surrounding environment, so as to improve the accumulation form, increase the compressive strength and increase the connected pores. The effect of rate and permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

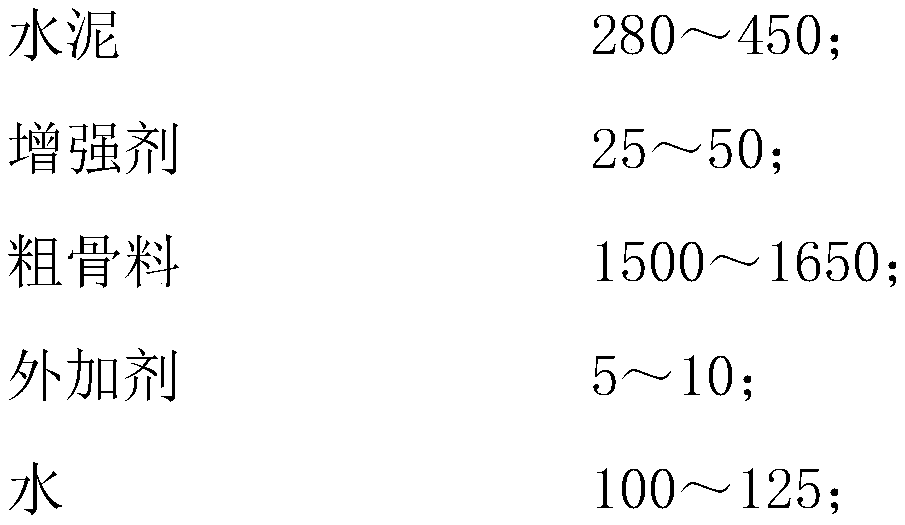

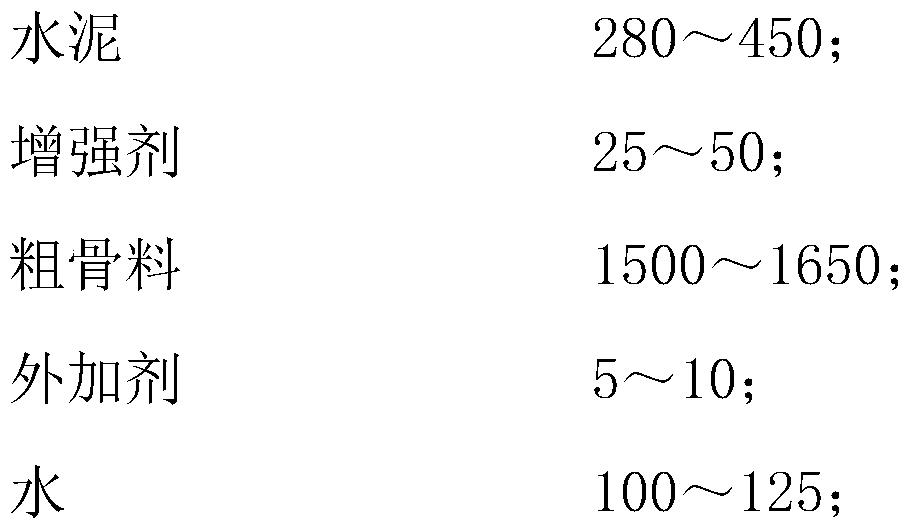

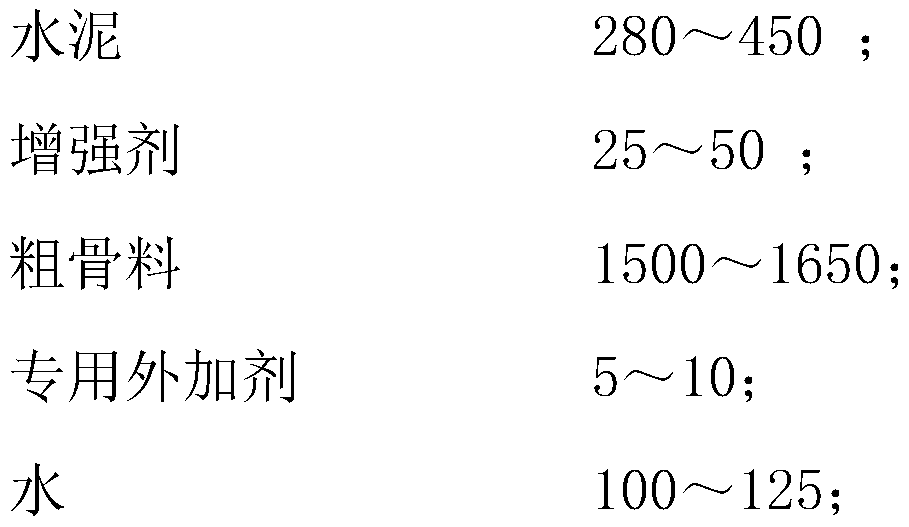

[0034] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] 1. Raw materials:

[0036] (1) Cement: Conch cement with strength grade P 042.5 is used;

[0037] (2) Coarse aggregate: 2.4-4.75mm and 9.5-13.2mm single-grained crushed stones are used to test the upper layer of pervious concrete and the lower layer of pervious concrete respectively. The aggregate crushing value index is 8.1%. Density is l600kg / m 3 、1540kg / m 3 , Strictly control the needle flake content of stones <15%;

[0038] (3) Reinforcing agent: The special permeable concrete reinforcing agent developed by our company is used. The reinforcing agent is a mixture of redispersible latex powder and silica fume. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap