Preparation method of foamed aluminum matrix loaded with Silicalite-1 molecular sieve anticorrosive film

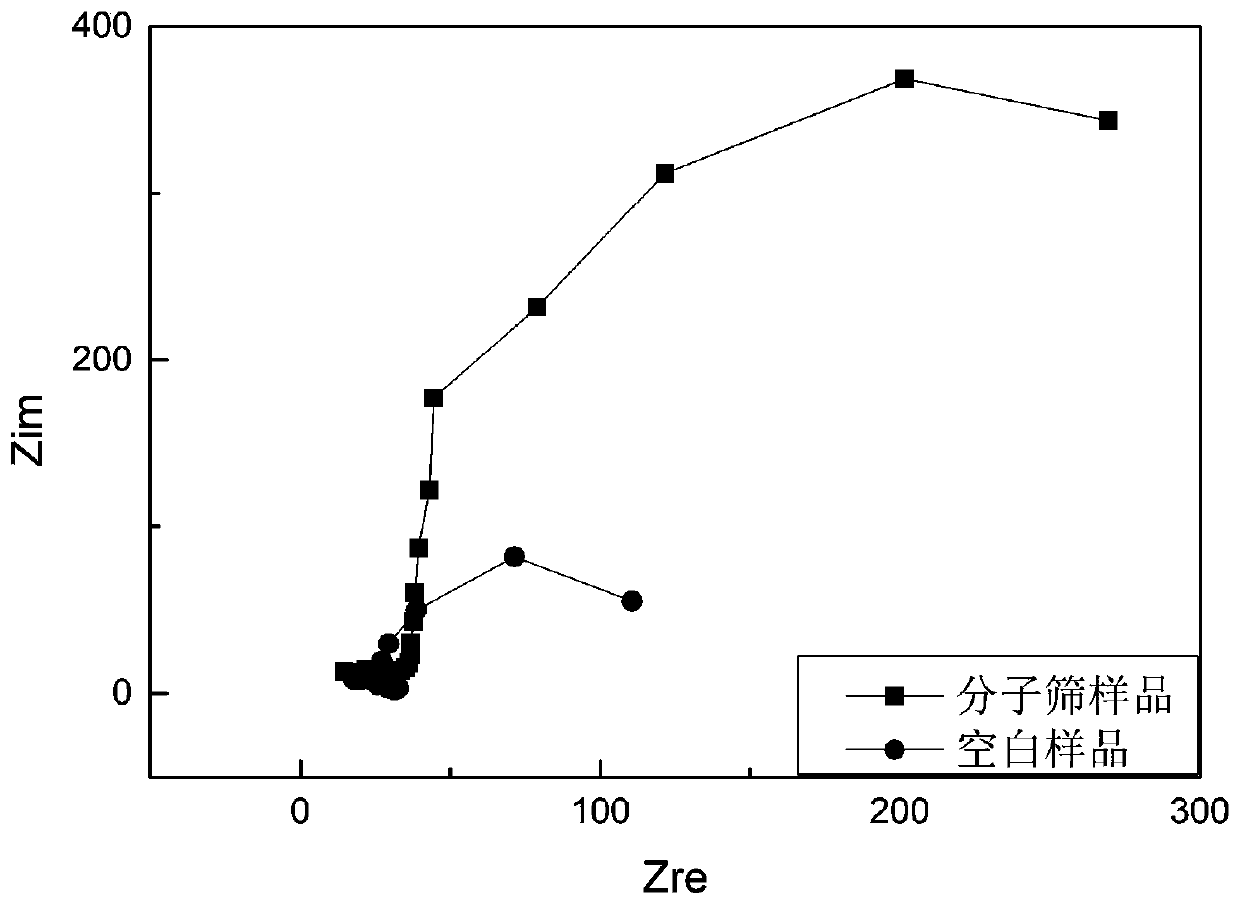

A technology of molecular sieve and aluminum foam, which is applied in the field of preparation of porous metal carrier coating, can solve the problems of anti-corrosion and other problems, and achieve the effect of improving binding force and anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

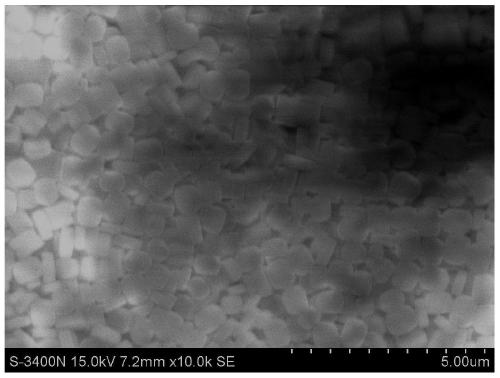

[0029] The preparation method of supporting Silicalite-1 molecular sieve anticorrosion film on the aluminum foam substrate provided by this embodiment includes the following steps carried out in order:

[0030] 1) Preparation of Silicalite-1 molecular sieve synthesis liquid:

[0031] Weigh 7.4g tetrapropylammonium hydroxide, 2.5g tetrapropylammonium hydroxide and 123.4g deionized water, then tetrapropylammonium hydroxide is dissolved in deionized water to make tetrapropylammonium hydroxide aqueous solution, after that Add tetrapropylammonium hydroxide dropwise to tetrapropylammonium hydroxide aqueous solution at a speed of 5 seconds per drop, and stir with a magnetic stirrer while adding dropwise until the solution is clear, thus making Silicalite-1 molecular sieve synthetic liquid;

[0032] 2) Preparation of Silicalite-1 molecular sieve powder:

[0033] Put the Silicalite-1 molecular sieve synthesis solution in a high-temperature and high-pressure reactor for hydrothermal cr...

Embodiment 2

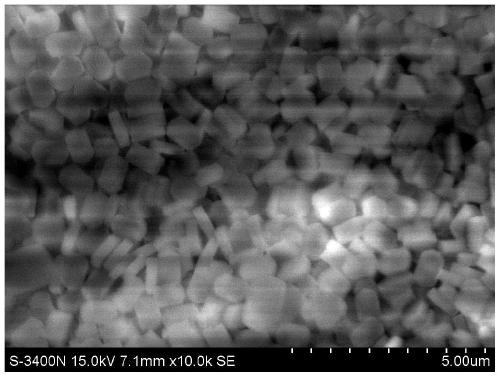

[0044] The preparation method of supporting Silicalite-1 molecular sieve anticorrosion film on the aluminum foam substrate provided by this embodiment includes the following steps carried out in order:

[0045] 1) Preparation of Silicalite-1 molecular sieve synthesis liquid:

[0046] Weigh 7.4g tetrapropylammonium hydroxide, 2.5g tetrapropylammonium hydroxide and 123.4g deionized water, then tetrapropylammonium hydroxide is dissolved in deionized water to make tetrapropylammonium hydroxide aqueous solution, after that Add tetrapropylammonium hydroxide dropwise to tetrapropylammonium hydroxide aqueous solution at a speed of 10s per drop, and stir with a magnetic stirrer while adding dropwise until the solution is clear, thus making Silicalite-1 molecular sieve synthetic liquid;

[0047] 2) Preparation of Silicalite-1 molecular sieve powder:

[0048] Put the Silicalite-1 molecular sieve synthesis liquid in a high-temperature and high-pressure reactor for hydrothermal crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com