High-strength elastic cloth and production technique thereof

A production process and high-strength technology, which is applied in the processing of textile materials, continuous processing of textile materials, textiles, etc., can solve the problems of poor comfort in use, achieve the prevention of bacterial growth, good tensile strength and elastic properties, and enhance softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

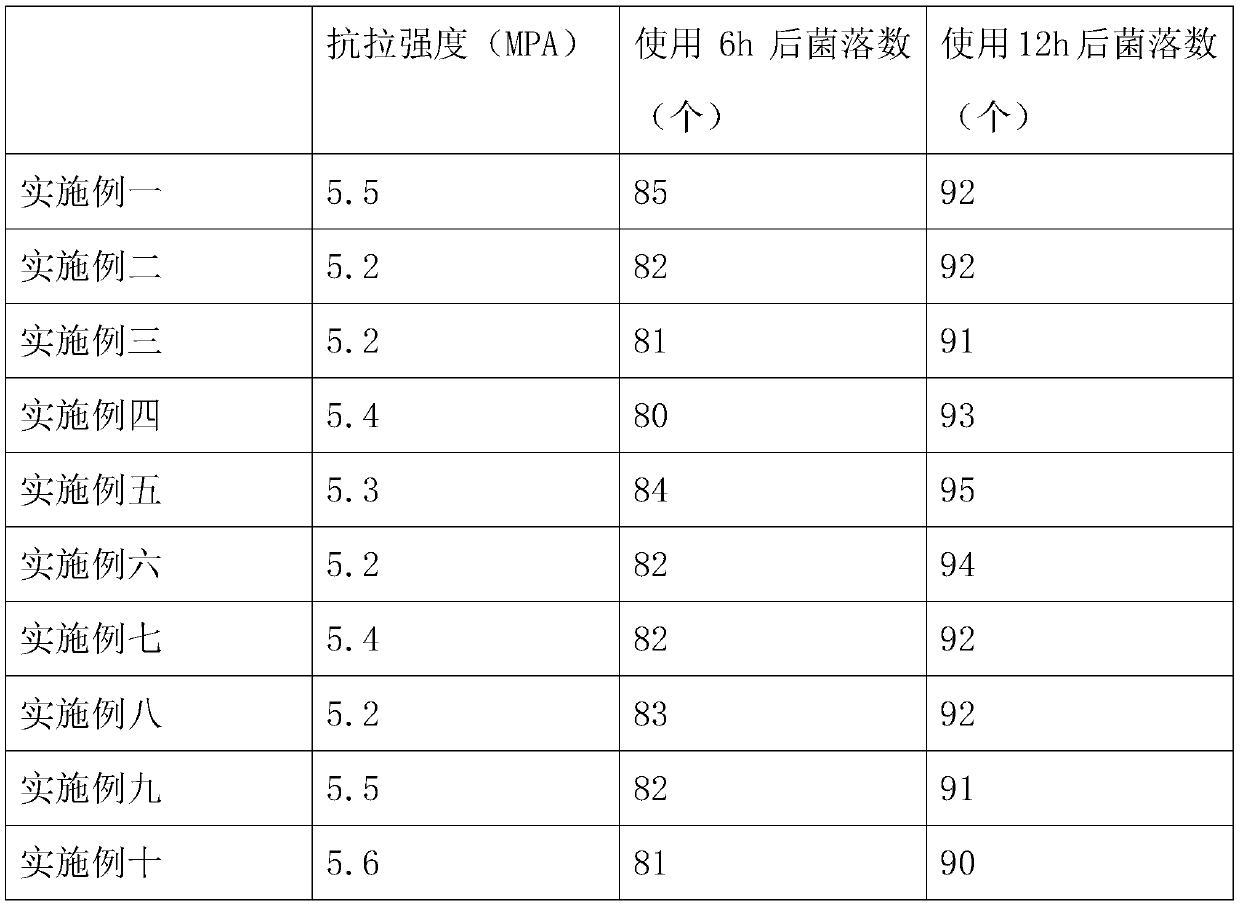

Examples

Embodiment 1

[0021] The cloth is made of the following raw materials in parts by weight: 40 parts of acrylic fiber, 7 parts of polyarylether sulfone, 1 part of nano-elastomer composite fiber, 2 parts of bamboo fiber, 1 part of omega mineral fiber, 4 parts of montmorillonite powder, chitin 2 parts of fiber, 3 parts of flame-retardant polyester fiber, 3 parts of cellulase solution, and 1 part of titanium dioxide.

[0022] The production technique of the present embodiment comprises the following steps:

[0023] A. Mix acrylic fiber, nano-elastomer composite fiber, bamboo fiber, omega mineral fiber, chitin fiber, flame-retardant polyester fiber, cellulase solution, and titanium dioxide and soak in the cellulase solution. Process to obtain blended fibers;

[0024] B. Add the blended fiber to acrylic fiber, polyarylether sulfone, and montmorillonite powder and mix fully, then add it to an airtight container for high-temperature setting and steaming to obtain yarn;

[0025] C, the yarn that st...

Embodiment 2

[0033] The fabric is made of the following raw materials in parts by weight: 50 parts of acrylic fiber, 14 parts of polyarylether sulfone, 3 parts of nano-elastomer composite fiber, 4 parts of bamboo fiber, 4 parts of omega mineral fiber, 10 parts of montmorillonite powder, chitin 5 parts of fiber, 7 parts of flame-retardant polyester fiber, 9 parts of cellulase solution, and 2 parts of titanium dioxide.

[0034] The production technique of the present embodiment comprises the following steps:

[0035] A. Mix acrylic fiber, nano-elastomer composite fiber, bamboo fiber, omega mineral fiber, chitin fiber, flame-retardant polyester fiber, cellulase solution, and titanium dioxide and soak in the cellulase solution. Process to obtain blended fibers;

[0036] B. Add the blended fiber to acrylic fiber, polyarylether sulfone, and montmorillonite powder and mix fully, then add it to an airtight container for high temperature setting and steaming to obtain yarn;

[0037] C, the yarn t...

Embodiment 3

[0045] The cloth is made of the following raw materials in parts by weight: 42 parts of acrylic fiber, 8 parts of polyarylether sulfone, 1 part of nano-elastomer composite fiber, 2 parts of bamboo fiber, 2 parts of omega mineral fiber, 5 parts of montmorillonite powder, chitin 3 parts of fiber, 4 parts of flame-retardant polyester fiber, 4 parts of cellulase solution, and 1 part of titanium dioxide.

[0046] The production technique of the present embodiment comprises the following steps:

[0047] A. Mix acrylic fiber, nano-elastomer composite fiber, bamboo fiber, omega mineral fiber, chitin fiber, flame-retardant polyester fiber, cellulase solution, and titanium dioxide and soak in the cellulase solution. Process to obtain blended fibers;

[0048] B. Add the blended fiber to acrylic fiber, polyarylether sulfone, and montmorillonite powder and mix fully, then add it to an airtight container for high temperature setting and steaming to obtain yarn;

[0049] C, the yarn that s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com