Construction method of tunnel entrance and exit hole

A construction method and technology for import and export, applied in the construction field of tunnel entrance and exit, can solve the problems of low bearing capacity, poor mountain stability, large mountain disturbance, etc., and achieve the effects of preventing excessive deformation, good use effect and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

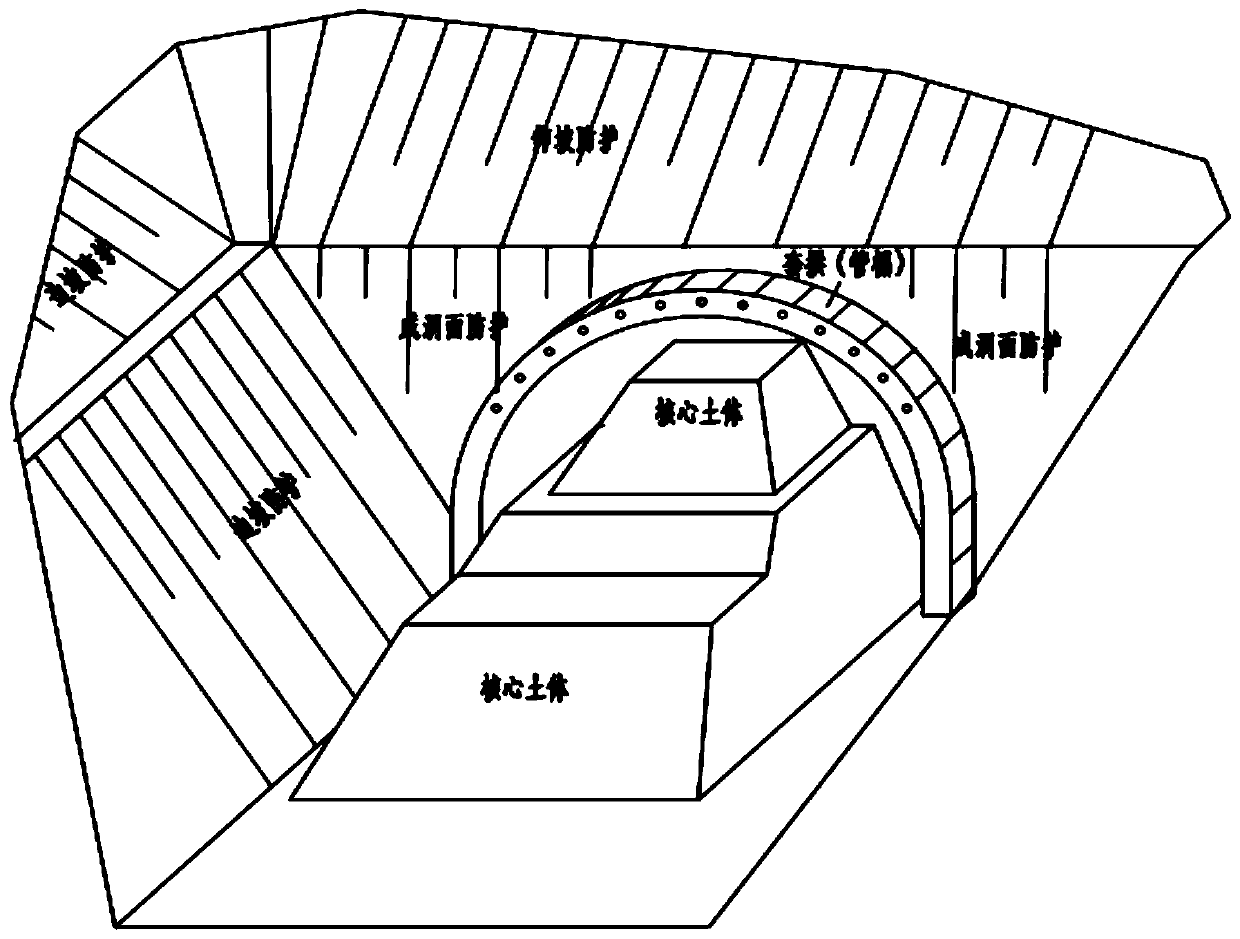

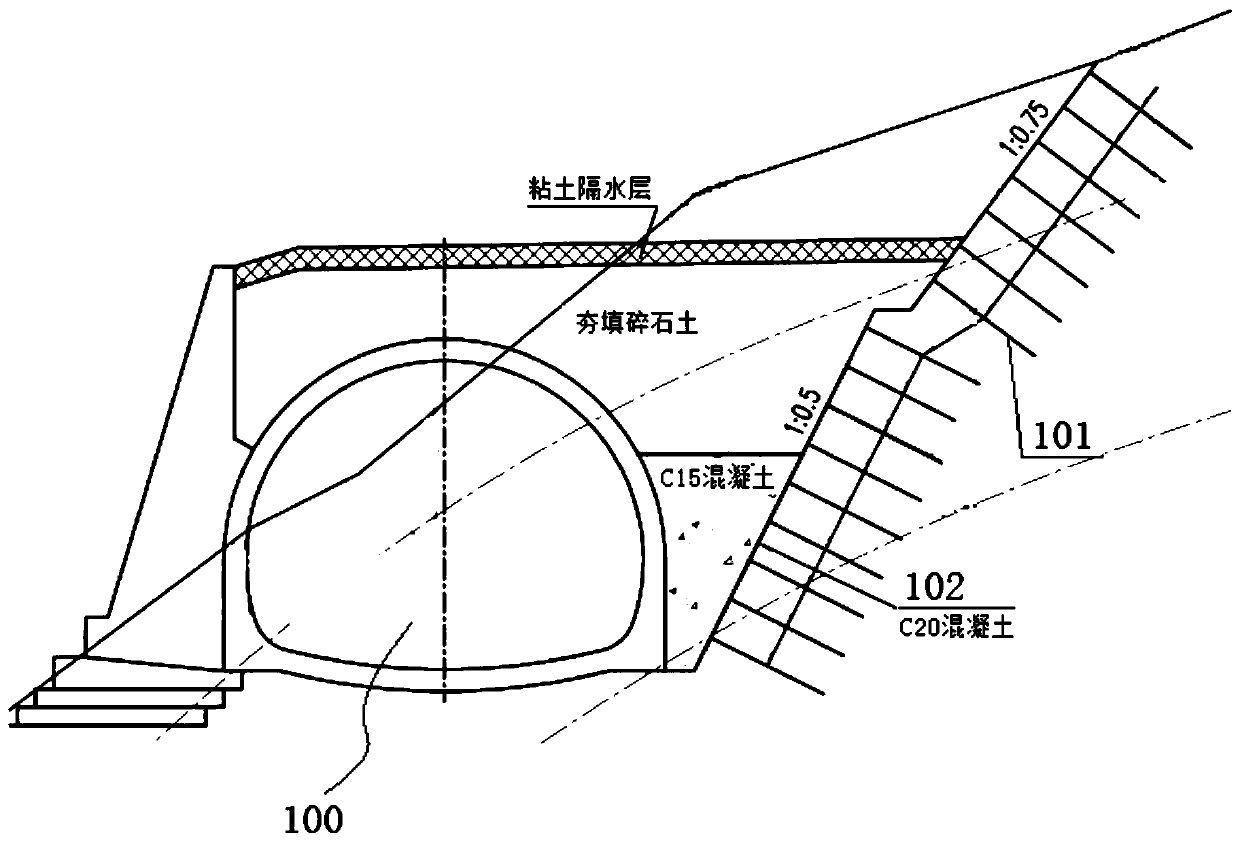

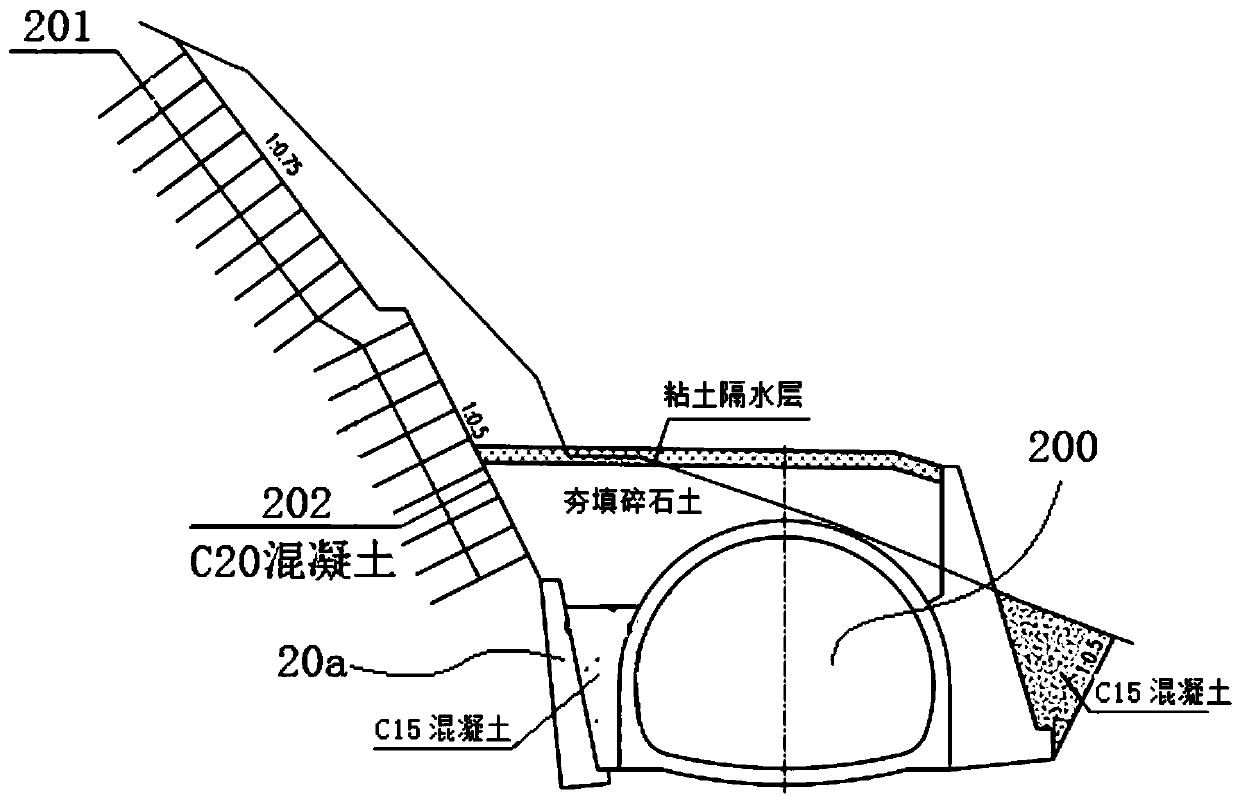

[0030] see Figure 1 to Figure 6 , The construction method of the tunnel entrance and exit hole of the present invention comprises the following processes: excavation of the intercepting ditch on the top of the hole; excavation of the hole, protection of the side of the hole, slope protection, arch construction and pipe shed construction.

[0031] When excavating the intercepting ditches on the top of the cave, construct the intercepting ditches on the top of the cave in advance at a horizontal distance of 5m from the excavation line of the cave entrance to prevent surface water from seeping into the excavation surface; Excavate in sections from the top to the high place and build with M10 mortar rubble to prevent erosion; set up rapids at the slope of the intercepting ditch greater than 20%, and set a platform every 2m at the base of the rapids to prevent sliding; rapids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com