LED fluorescence emission spectrum-based surface temperature measurement method

A surface temperature and measurement method technology, which is applied to thermometers, thermometers, and measuring devices with physical/chemical changes, can solve problems such as difficult temperature measurement and poor surface flatness of white light LEDs, and achieve wide application, good consistency, and avoid The effect of man-made damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

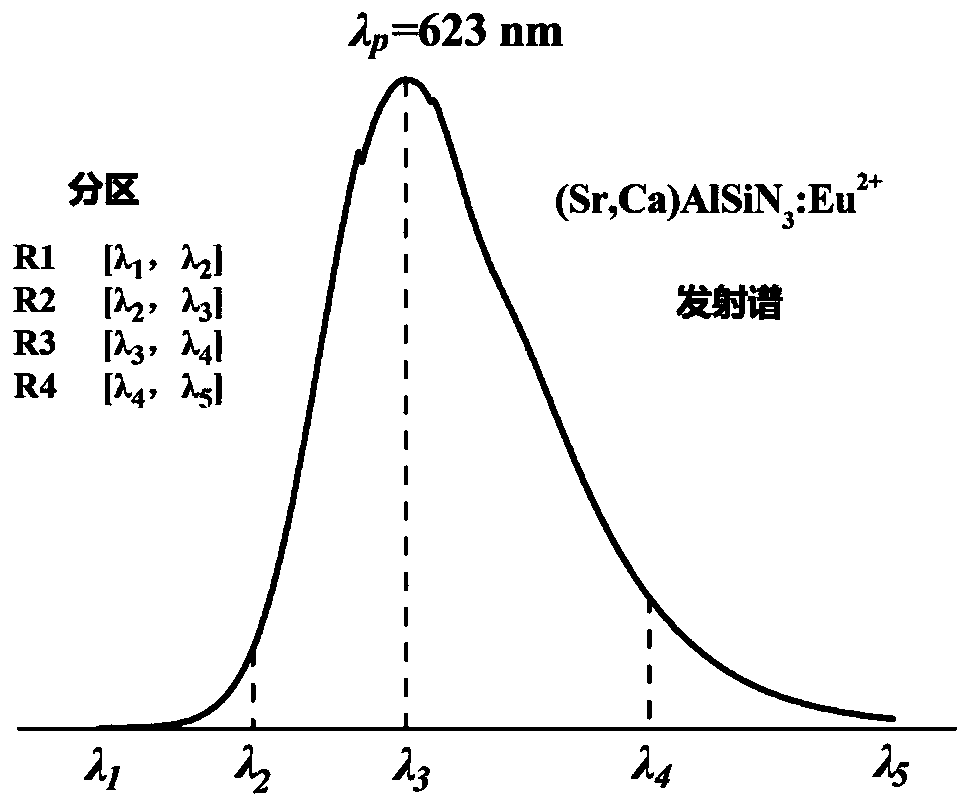

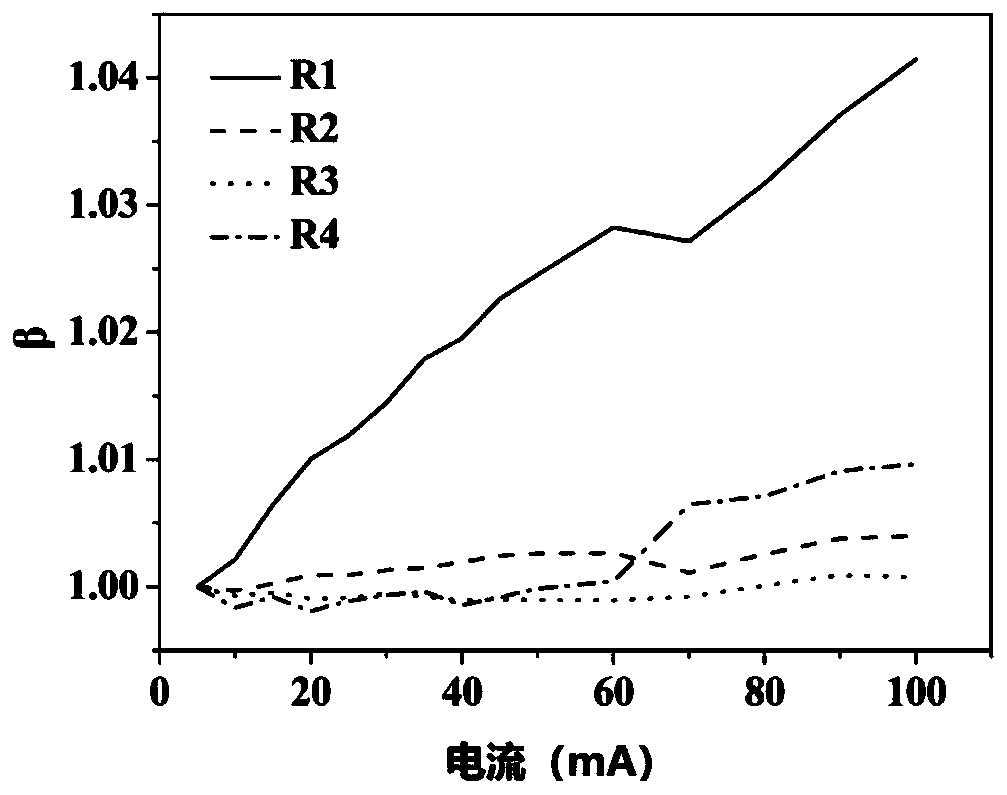

Method used

Image

Examples

Embodiment 1

[0047] (1) Fix the LED sample 1 to be tested on the temperature control table, and then connect a constant current source to power the LED sample 1 to be tested; wherein, in the LED sample 1, the fluorescent material is (Si, Ca)AlSiN 3 :Eu 2+ A mixture of red fluorescent powder and silica gel at a mass ratio of 1:4.

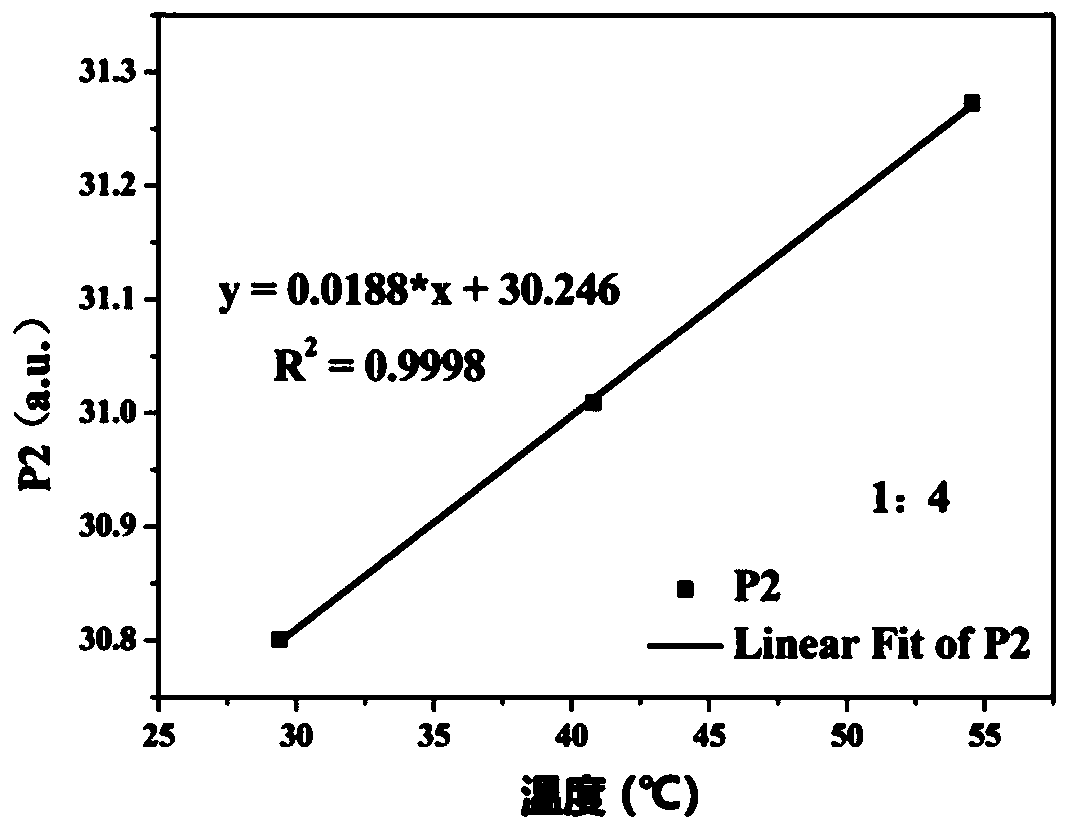

[0048] (2) Select an appropriate small current of 10mA to light up the LED sample 1 to be tested, and then select a set of suitable temperatures T0=30°C, T1=45°C, T2=60°C (generally lower than the failure temperature of the LED sample to be tested , the failure temperature of LED sample 1 in this embodiment is about 140°C), the respective spectra of fluorescent materials at T0, T1, and T2 temperatures are collected by a spectrometer, and the P2 value of the emission spectrum of the fluorescent material is calculated, and finally T0, T1, The functional relationship between T2 and P2, such as image 3 Shown is the calibration curve fitted by P2.

[0049] (3) Adj...

Embodiment 2

[0054] The test method and conditions of Example 2 are the same as those of Example 1, the difference is that in the LED sample 2 to be tested, the fluorescent material is (Si, Ca)AlSiN 3 :Eu 2+ A mixture of red fluorescent powder and silica gel at a mass ratio of 1:5.

[0055] Figure 4 It is the calibration curve fitted by P2; Table 2 is the comparison result of the calculated fitting temperature Tc and the thermocouple temperature Tt.

[0056]

[0057] Table 2

Embodiment 3

[0059] The test method and conditions of Example 3 are the same as those of Example 1, the difference is that in the LED sample 3 to be tested, the fluorescent material is (Si, Ca)AlSiN 3 :Eu 2+ A mixture of red fluorescent powder and silica gel at a mass ratio of 1:10.

[0060] Figure 5 It is the calibration curve fitted by P2; Table 3 is the comparison result of the calculated fitting temperature Tc and the thermocouple temperature Tt.

[0061]

[0062] table 3

[0063] Through the data results of the above examples, it can be seen that the temperature difference between the temperature of LED sample 1, LED sample 2 and LED sample 3 under five different currents and the temperature of the micro-thermocouple is within 5°C, showing good Consistency, further illustrates the feasibility of the method of the present invention, the temperature difference may be partly derived from thermocouple light absorption.

[0064] The method of the present invention is applicable to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com