A Hall thruster accelerated life test method

An accelerated life test, Hall thruster technology, applied in thrust reversers, instruments, machines/engines, etc., can solve the problems of long cycle, high cost, low accelerated test efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

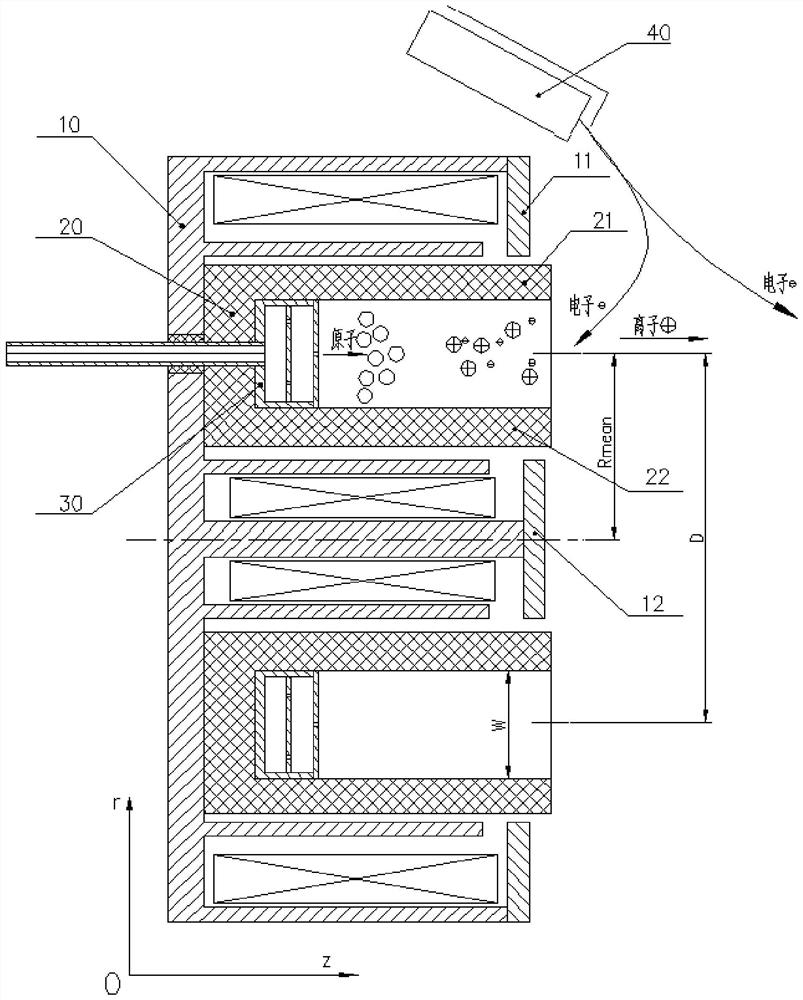

[0166] During the accelerated life test of the Hall thruster, an example of the selection of the actual running time and the predicted time is listed below. A certain type of 5kW Hall thruster is selected as an example for the accelerated life test. The discharge channel of the thruster at the beginning of its life The average diameter D is φ120mm, the width W of the discharge channel is 20mm, the thickness of the inner wall of the discharge channel is 10mm, and the thickness of the outer wall of the discharge channel is 10mm.

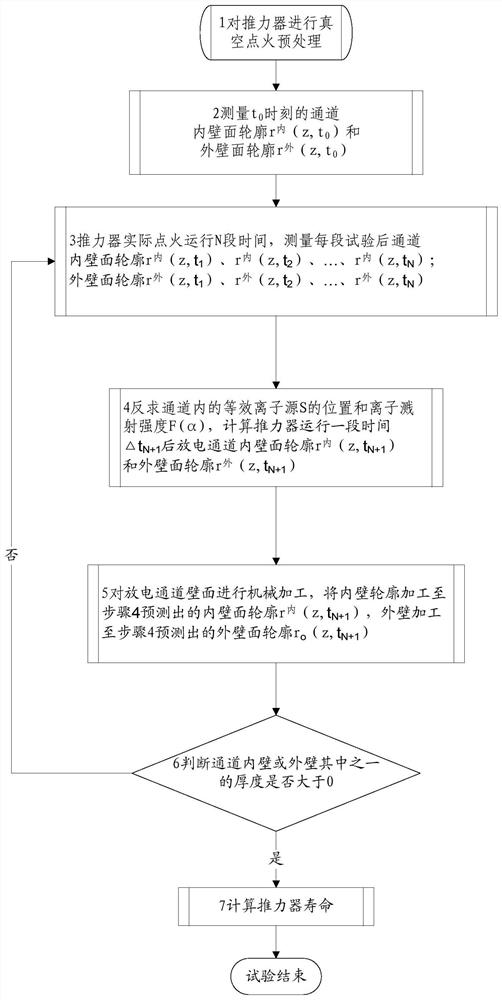

[0167] (1) Before the official operation of the thruster, a pretreatment exhaust time of 10 hours is performed, and this time is recorded as time 0;

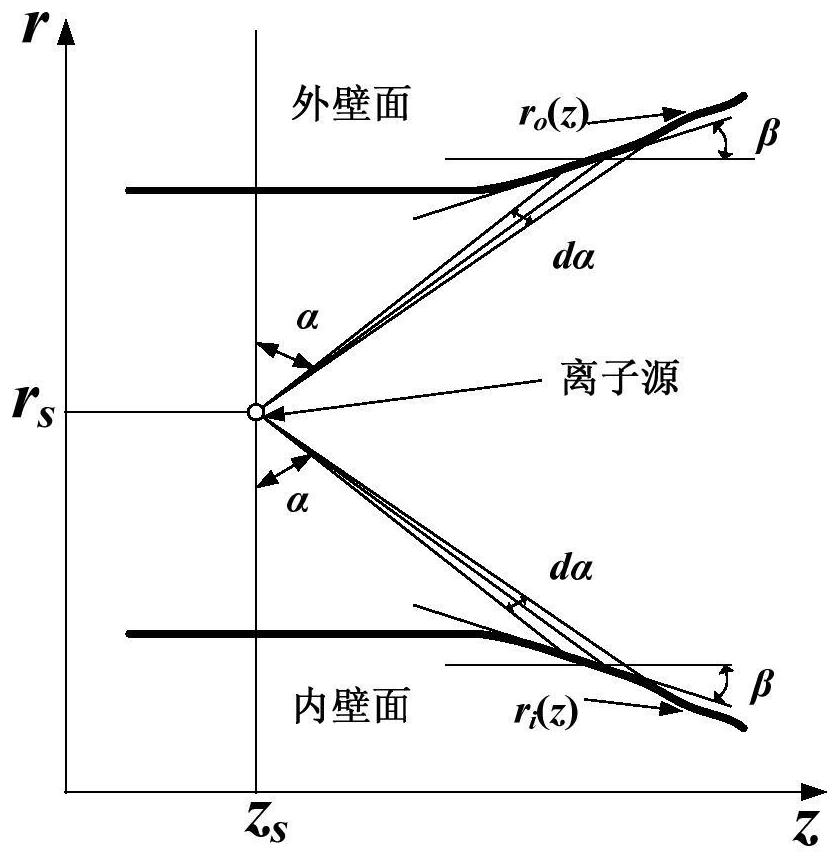

[0168] (2) Carry out the 0-200hr running test on the thruster, the profile measurement time is selected as 0, 100hr, and 200hr, and the wall profile of 400hr is obtained according to the extrapolation and prediction of the wall profile at these three moments, see Figure 6 shown;

[0169] (3) Process th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com