Method for preparing tin-based sulfide lithium ion battery negative active material under room temperature

A negative electrode active material, tin-based sulfide technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large volume change and short cycle life of tin-based negative electrode materials, and achieves short reaction cycle time and improved efficiency. The effect of high cycle life and specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

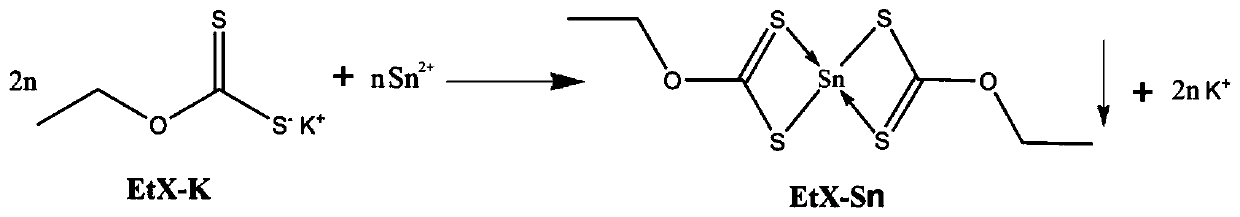

[0036] Embodiment 1: The method for preparing the negative electrode active material of a tin-based sulfide lithium ion battery at room temperature in this embodiment is carried out according to the following steps:

[0037] 1. SnCl 2 ·2H 2 O is dissolved in deionized water to obtain solution a;

[0038] 2. Dissolving potassium ethyl xanthate in deionized water to obtain solution b;

[0039] 3. Dispersing the conductive carbon material into deionized water to obtain dispersion c;

[0040] 4. Mix the solution a and the dispersion c and continue to stir to obtain the solution d;

[0041] 5. Add solution b dropwise to solution d under stirring, stop stirring after the dropwise addition is completed, seal the container containing solution d, and finally stand for treatment to obtain a precipitated product;

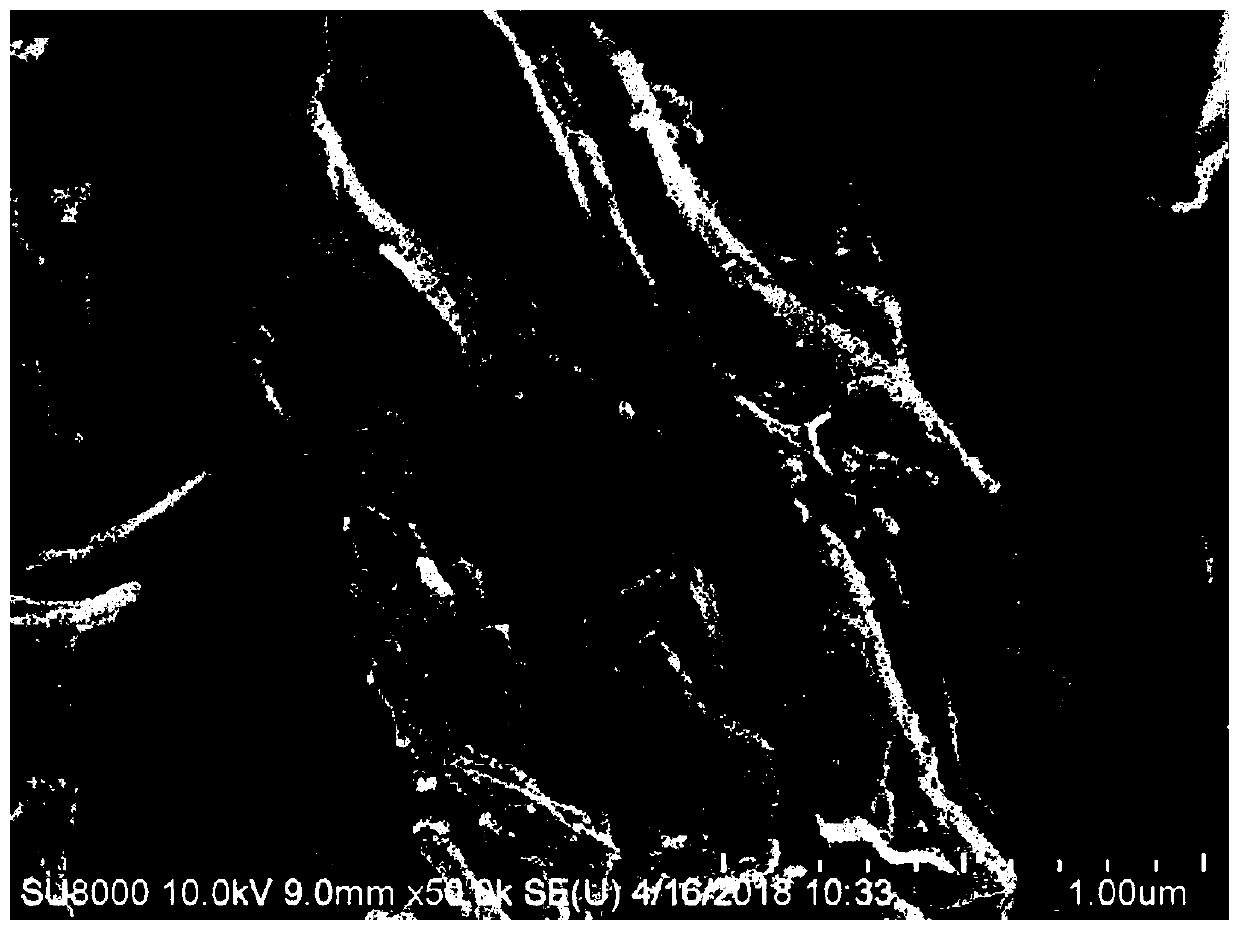

[0042] Sixth, taking the precipitation product obtained in step 5, and sequentially performing suction filtration, washing with deionized water and vacuum drying on the pr...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar concentration of Sn ions in the solution a in step 1 is 0.2-4M. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of potassium ethyl xanthate in the solution b in step 2 is 0.2-2%. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com