Control method for avoiding S roller slippage of single-stand cold-rolling strip steel smoothing machine

A technology of cold-rolled strip steel and control method, applied in rolling mill control device, metal rolling, metal rolling and other directions, can solve the problems of inability to completely solve the problem of slippage, short roll changing period, poor feasibility, etc., and achieves low cost, Avoid S-roll slippage and achieve simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0044] The invention provides a control method for avoiding slipping of S rolls of a single-stand cold-rolled strip tempering machine.

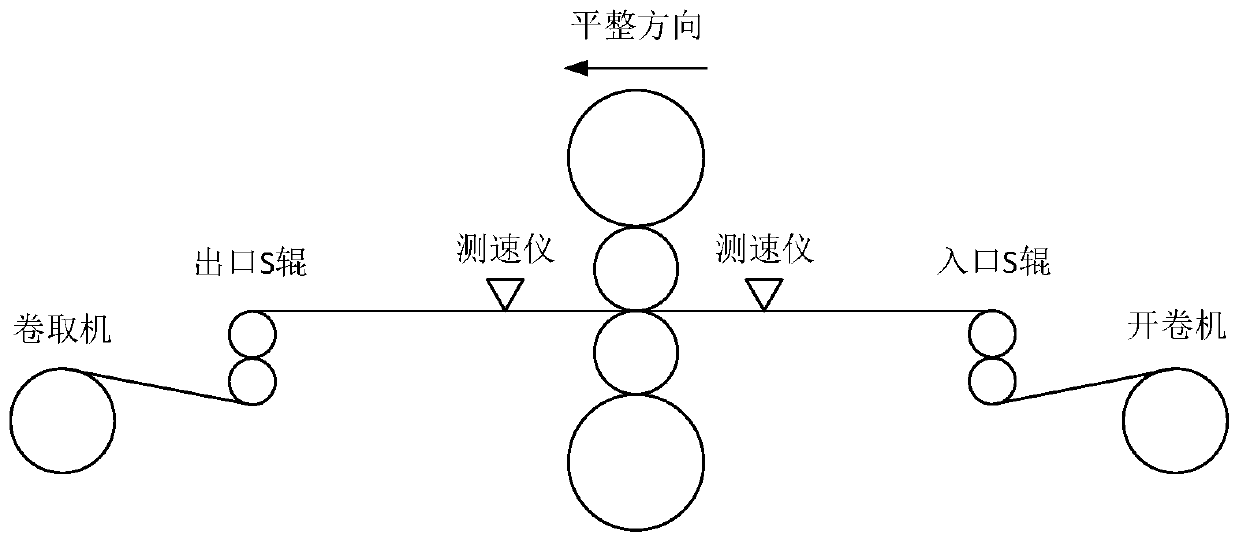

[0045] The equipment involved in this method is figure 1 As shown, according to the thickness of the smooth strip, the control mode of the S roll is switched between the torque control mode and the speed control mode, wherein the torque control mode is to give the S roll a speed ahead or behind the strip, Then the torque is tension-limited to make it work in a torque closed-loop; the speed control mode is to use the measured strip speed as the given speed of the S roller, and at the same time limit the torque of the S roller to a small extent.

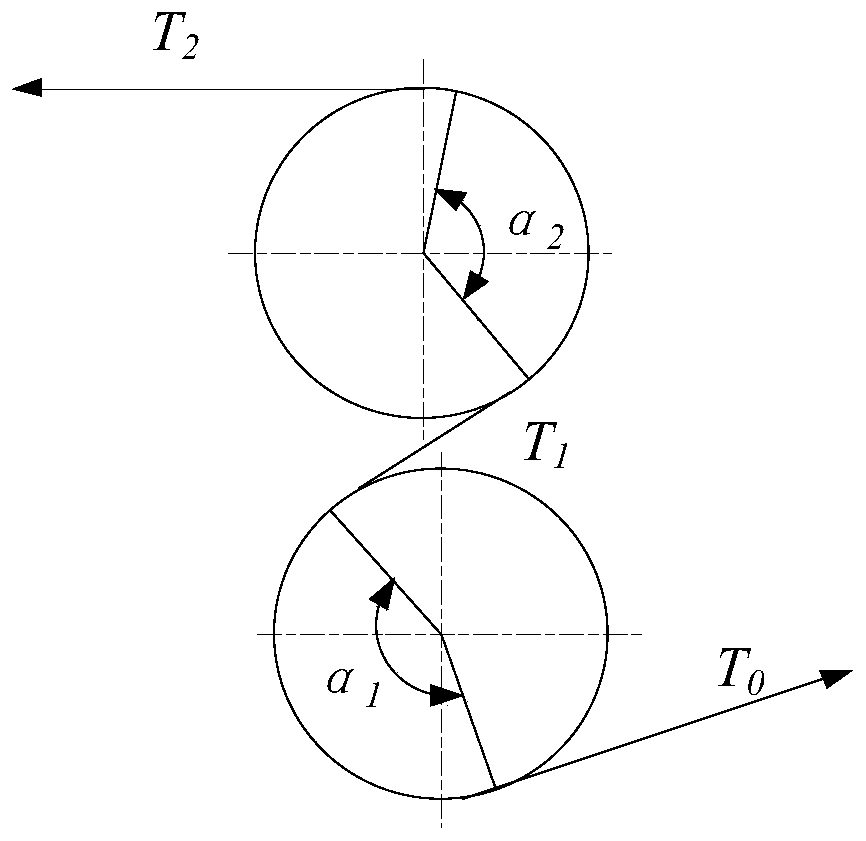

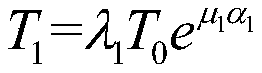

[0046] Such as figure 2Shown is the force analysis diagram of the S roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com