Low-noise environmentally-friendly pneumatic chain saw

A low-noise, chain saw technology, applied in sawing machine devices, metal sawing equipment, sawing machine attachments, etc., can solve the problems of asynchronous work, limited dust reduction effect, waste of water resources, etc., to optimize the cooling function and protect the body. Health, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A low-noise environment-friendly pneumatic chain saw of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

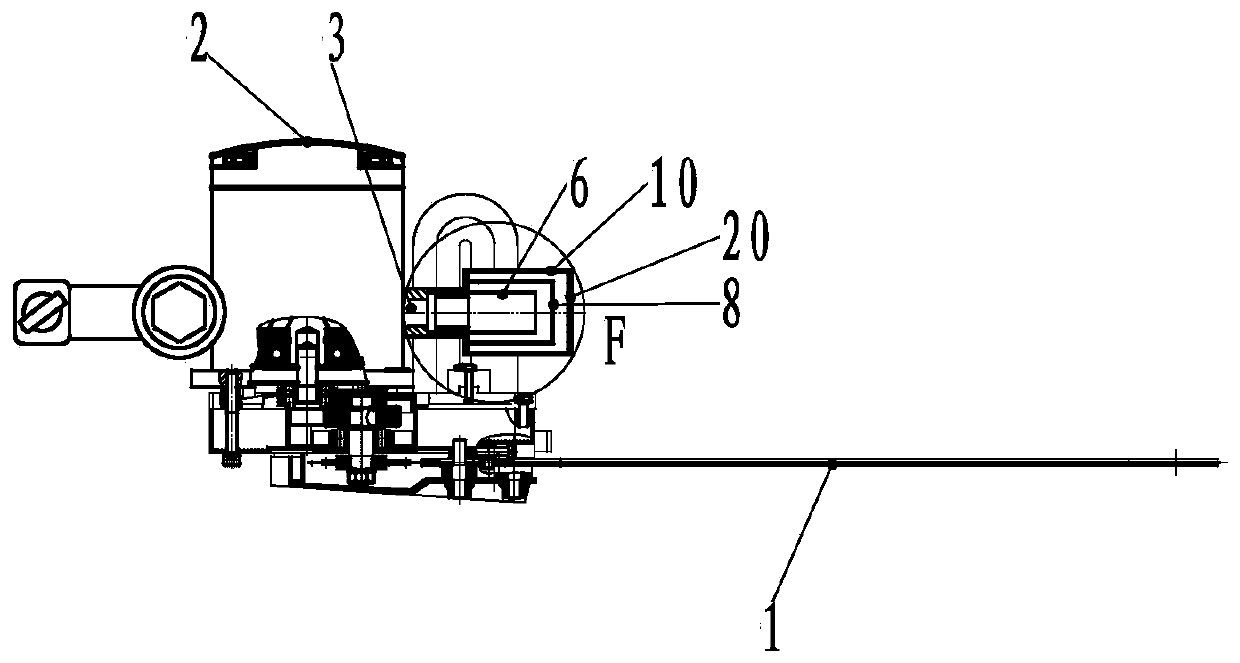

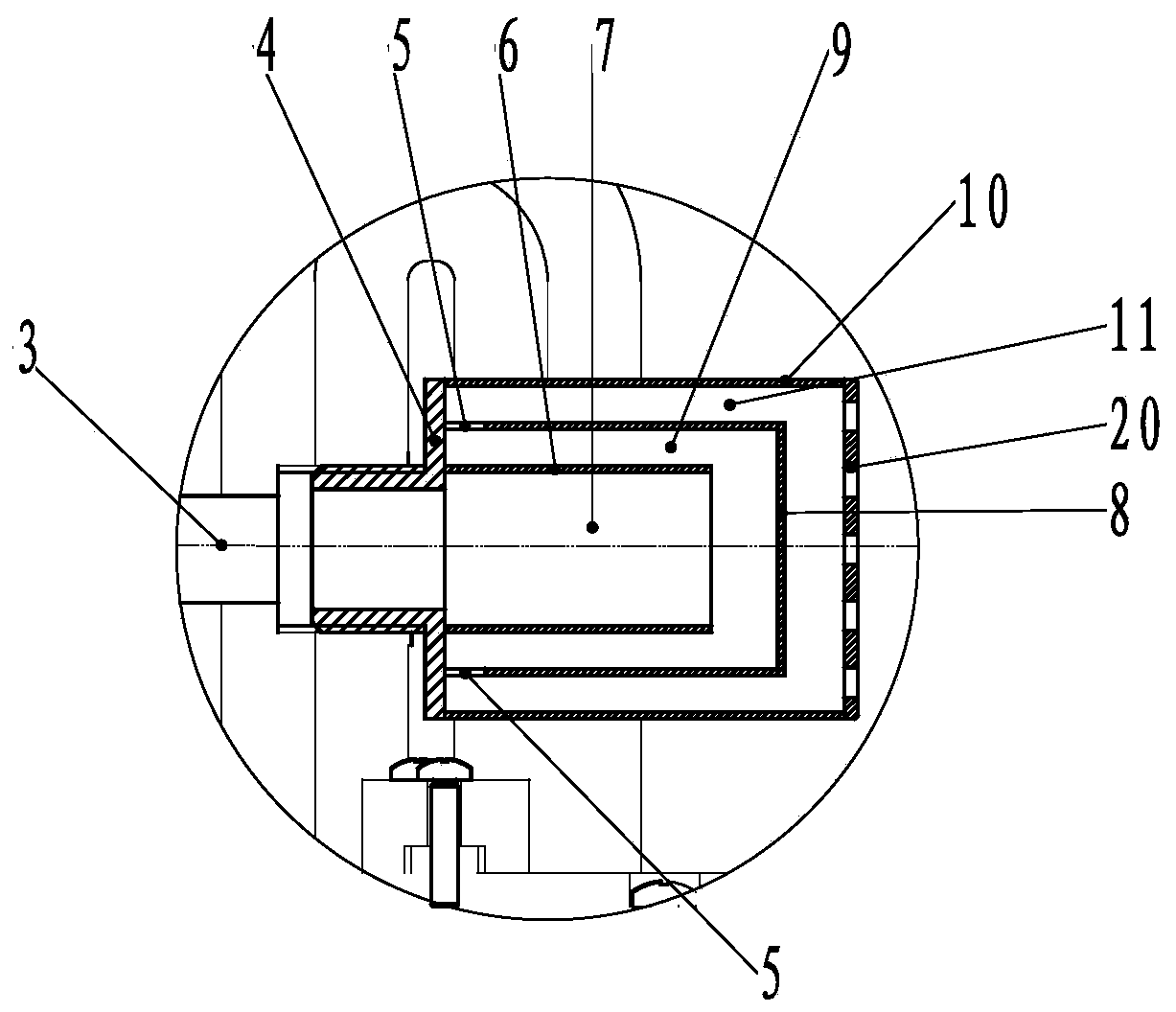

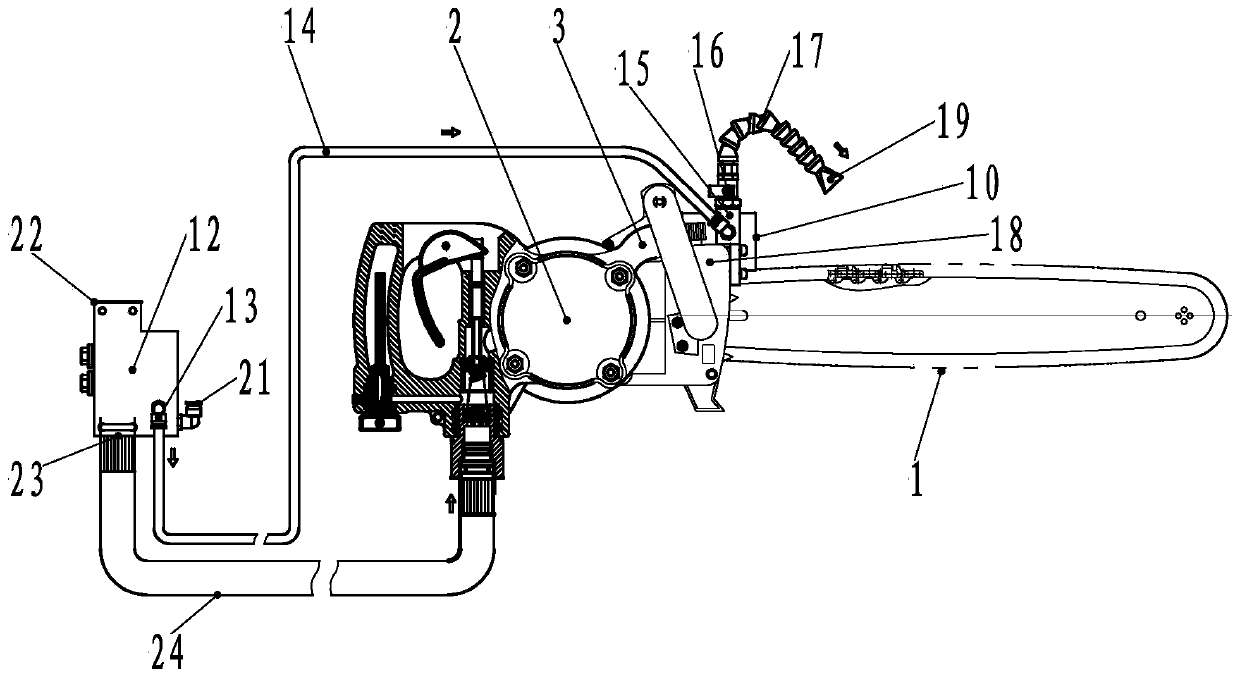

[0018] figure 1 It is a structural schematic diagram of a low-noise environment-friendly pneumatic chain saw of the present invention, figure 2 yes figure 1 Enlarged view of middle F, image 3 yes figure 1 top view. In the figure, the pneumatic saw blade includes a saw blade 1, a casing 18, an air-water linkage water cut-off protector 12 located outside the machine body, a water outlet 13 on the air-water linkage water cut-off protector 9, an air motor 2, and the air motor 2. Exhaust pipe outlet 3, the exhaust pipe outlet 3 of the air motor 2 is provided with a disk base 4, and a sound guide tube 6 is arranged on the disk base 4, and the main sound channel communicating with the air motor exhaust pipe outlet 3 is arranged in the sound guide tube 6 7. The outside of the sound guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com