A drawing device for small viscosity glass tube

A glass tube and viscosity technology, which is applied in the vertical drawing of glass liquid, glass forming, glass manufacturing equipment, etc., can solve the problems of complicated operation, large production batch, difficult to control heating flow, etc., and achieve simple equipment configuration and structure. , The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

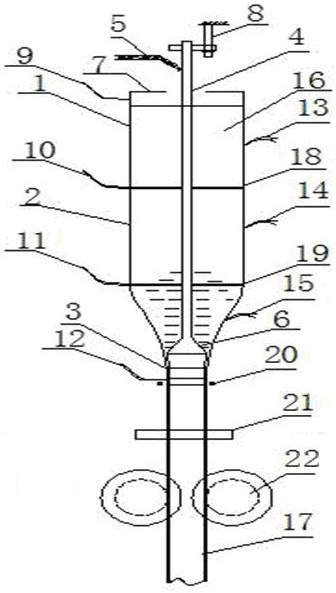

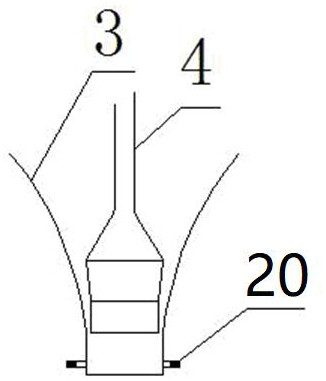

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] implemented as Figure 1 to Figure 5 shown. A low-viscosity glass tube drawing device of the present invention comprises a top-to-bottom connecting barrel 1, a viscosity adjusting barrel 2 and a molding die 3, a glass tube outer diameter detection device 21 is arranged below the molding die 3, It has the function of detecting the outer diameter of the tube. A glass tube traction device 22 is provided below the glass tube outer diameter detection device 21. A nozzle heating device 20 is provided at the outlet below the forming mold. The nozzle heating device 20 is a strip heating device. The material connecting cylinder 1, the viscosity adjusting cylinder 2 and the forming mold 3 are all equipped with electrodes correspondingly, which can be directly energized and heated, wherein the viscosity adjusting cylinder 2, the material connecting cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com