A kind of environment-friendly flame-retardant plastic masterbatch that prevents blowout frost precipitation and its preparation method

A flame-retardant plastic, environmentally friendly technology, applied in the field of flame-retardant plastics, to achieve the effect of increasing compatibility, reducing the release of small molecules, and excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

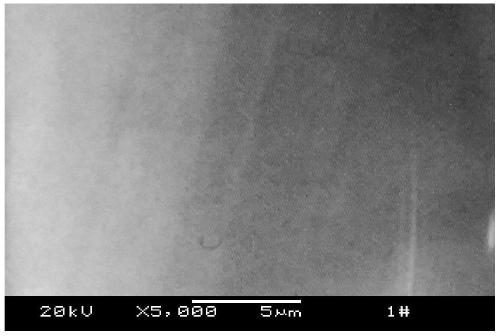

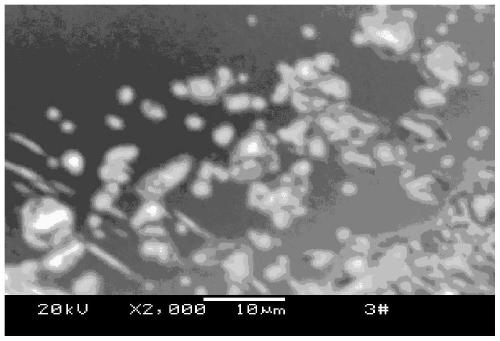

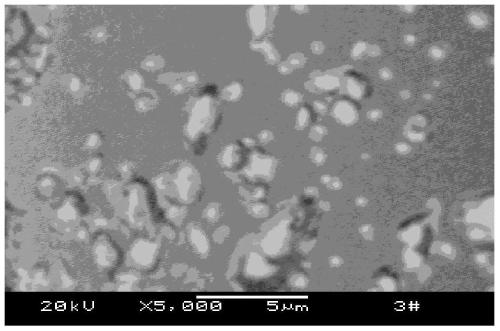

Image

Examples

Embodiment 1

[0039] (1) Grinding the silicone powder and aluminum sulfate, then adding deionized water to obtain the aluminum sulfate composite liquid for dispersing the silicone powder for subsequent use; wherein the mass ratio of silicone powder, aluminum sulfate, and deionized water is 1:5:20 ;

[0040] (2) Compound long-chain ammonium polyphosphate with n>500, commercially available phosphorus content greater than 14%, and melamine polyphosphate salt with nitrogen content greater than 38% at a mass ratio of 3:1, and obtain the particle size by vortex jet mill treatment Composite micropowder less than 5μm;

[0041] (3) Add the composite micropowder into the airtight container to ensure that the amount of the composite micropowder in the airtight container does not exceed 1 / 3 of the capacity of the airtight container, fill the airtight container with ammonia gas, control the temperature of the container to 45°C, and stir at a high speed of 800rpm , the composite micropowder is preferabl...

Embodiment 2

[0046] (1) Grinding the silicone powder and aluminum sulfate, then adding deionized water to obtain the aluminum sulfate composite liquid for dispersing the silicone powder for subsequent use; wherein the mass ratio of silicone powder, aluminum sulfate, and deionized water is 1:5:20 ;

[0047] (2) Compound long-chain ammonium polyphosphate with n>500, commercially available phosphorus content greater than 14%, and melamine polyphosphate salt with nitrogen content greater than 38% at a mass ratio of 3:1, and obtain the particle size by vortex jet mill treatment Composite micropowder less than 5μm;

[0048] (3) Add the composite micropowder into the airtight container to ensure that the amount of the composite micropowder in the airtight container does not exceed 1 / 3 of the capacity of the airtight container, fill the airtight container with ammonia gas, control the temperature of the container to 35°C, and stir at a high speed of 1200rpm , the composite micropowder is preferab...

Embodiment 3

[0053] (1) Grinding the silicone powder and aluminum sulfate, then adding deionized water to obtain the aluminum sulfate composite liquid for dispersing the silicone powder for subsequent use; wherein the mass ratio of silicone powder, aluminum sulfate, and deionized water is 1:5:20 ;

[0054] (2) Compound long-chain ammonium polyphosphate with n>500, commercially available phosphorus content greater than 14%, and melamine polyphosphate salt with nitrogen content greater than 38% at a mass ratio of 3:1, and obtain the particle size by vortex jet mill treatment Composite micropowder less than 5μm;

[0055] (3) Add the composite micropowder into the airtight container to ensure that the amount of the composite micropowder in the airtight container does not exceed 1 / 3 of the capacity of the airtight container, fill the airtight container with ammonia gas, control the temperature of the container to 45°C, and stir at a high speed of 1200rpm , the composite micropowder is preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com