Preparing method of raw stock vinegar prepared from nine kinds of cereals

The technology of vinegar liquid and chaff, which is applied in the field of preparation of nine-grain puree vinegar, can solve the problems of lack of nutrients, single sour and irritating taste, thin overall texture and the like, and achieves the effects of rich nutrients, rich taste and thick texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: the raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: 23kg of millet, 20kg of barley, 17kg of corn, 34kg of sorghum, 11kg of wheat, 10kg of peas, 63kg of wheat bran, and 32kg of rice husk , chaff 27kg;

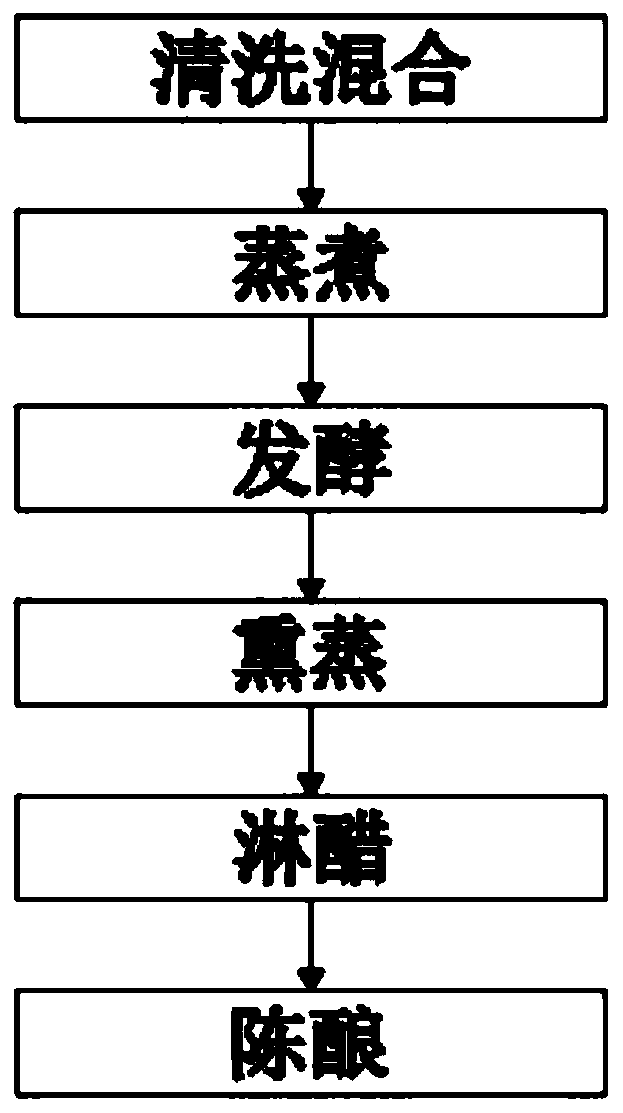

[0027] The specific preparation method steps of the preparation method of this Jiugu puree vinegar are as follows:

[0028] S1: Cleaning and mixing: millet, barley, corn, sorghum, wheat, pea, wheat bran, rice husk, and chaff are sorted and cleaned according to the mass ratio. After cleaning, crushing is required, and the raw materials are crushed into 2 or 3 stages. , the particle size of the crushed particles is 1-1.5mm, remove the impurities and mildew spots on the surface, take out the millet, barley, corn, sorghum, wheat, and peas and put them in the mixing equipment, and add Daqu for stirring and mixing, Daqu Before adding, it n...

Embodiment 2

[0037] The raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: the raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: 20kg of millet, 18kg of barley, 15kg of corn, 32kg of sorghum, 10kg of wheat, 8kg of peas, 60kg of wheat bran, and 30kg of rice husk , chaff 25kg;

[0038] The specific preparation method steps of the preparation method of this Jiugu puree vinegar are as follows:

[0039]S1: Cleaning and mixing: millet, barley, corn, sorghum, wheat, pea, wheat bran, rice husk, and chaff are sorted and cleaned according to the mass ratio. After cleaning, crushing is required, and the raw materials are crushed into 2 or 3 stages. , the particle size of the pulverized particles is 1mm, and the impurities and mold spots on the surface are removed, and the millet, barley, corn, sorghum, wheat, and peas are taken out and placed in the mixing equipment, and Daqu is added for stirring and mixing. It needs...

Embodiment 3

[0048] The raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: the raw materials of the Jiugu puree vinegar are respectively according to the mass proportion: 25kg of millet, 22kg of barley, 20kg of corn, 35kg of sorghum, 12kg of wheat, 12kg of peas, 65kg of wheat bran, and 33kg of rice husk , chaff 29kg;

[0049] The specific preparation method steps of the preparation method of this Jiugu puree vinegar are as follows:

[0050] S1: Cleaning and mixing: millet, barley, corn, sorghum, wheat, pea, wheat bran, rice husk, and chaff are sorted and cleaned according to the mass ratio. After cleaning, crushing is required, and the raw materials are crushed into 2 or 3 stages. , the particle size of the crushed particles is 1-1.5mm, remove the impurities and mildew spots on the surface, take out the millet, barley, corn, sorghum, wheat, and peas and put them in the mixing equipment, and add Daqu for stirring and mixing, Daqu It needs to be crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com