Method of preparing super-hydrophobic fabric by plasma treatment of nano particle composite coating

A nanoparticle and plasma technology, applied in the field of ion finishing, can solve problems such as poor durability, complicated process, and non-environmental protection, and achieve the effect of green environmental protection and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing superhydrophobic fabrics through plasma treatment of nanoparticle composite coatings:

[0029] (1) Configure 2g / L detergent 209 and anhydrous sodium carbonate solution, the solution pH=8, soak the polyester fabric in the detergent solution with a bath ratio of 50:1, ultrasonically clean it for 40min, and then wash it with deionized water 3-5 times, put it in the oven to dry, take it out and set aside.

[0030] (2) Cut the pretreated polyester fabric into a size of 40mm×50mm, and place it in 5g / L PDMS and 0.7g / L nano TiO 2 Particles were immersed in an alcohol solution with a bath ratio of 30:1 for 10 minutes in an ultrasonic cleaner, and dried at 60°C after taking it out.

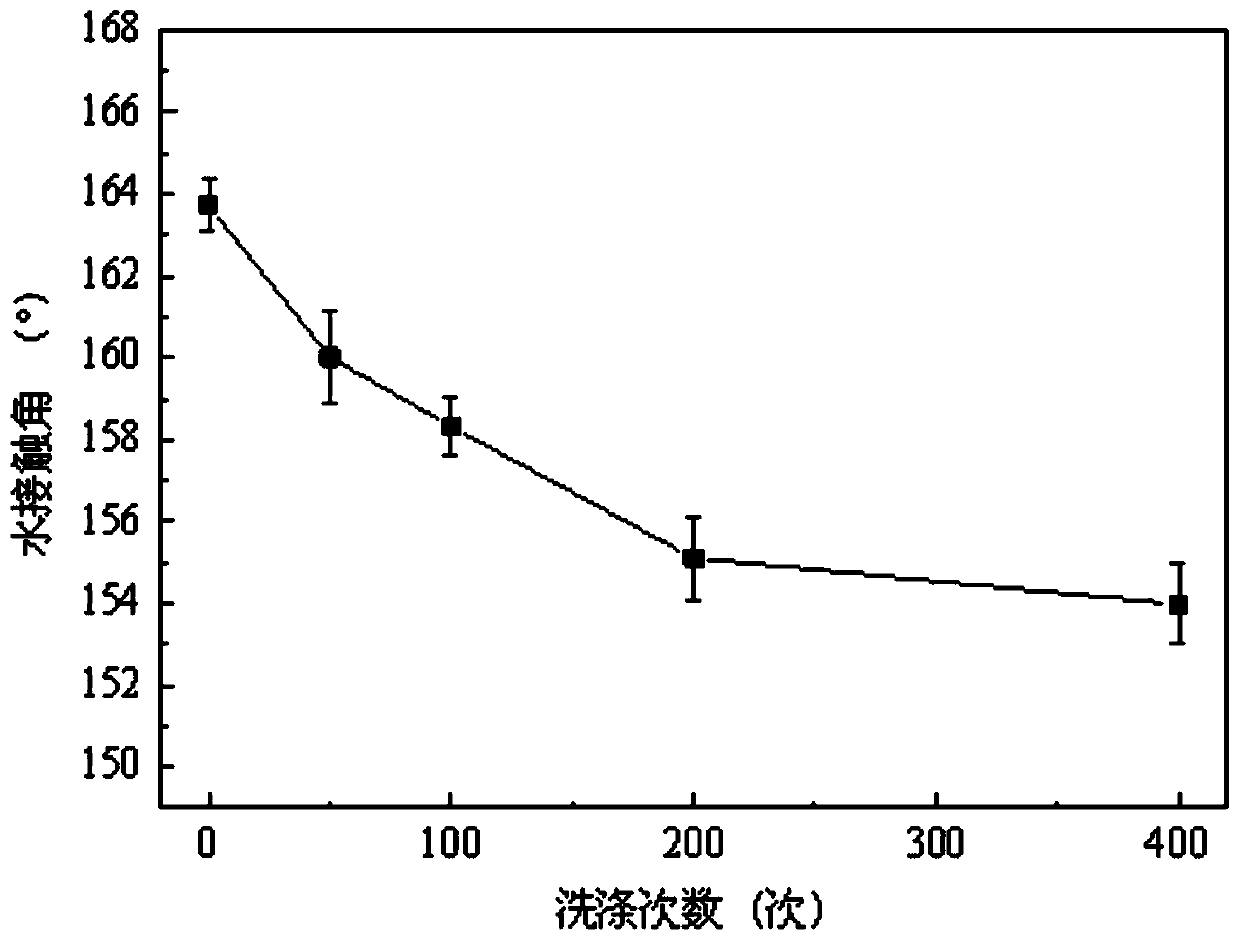

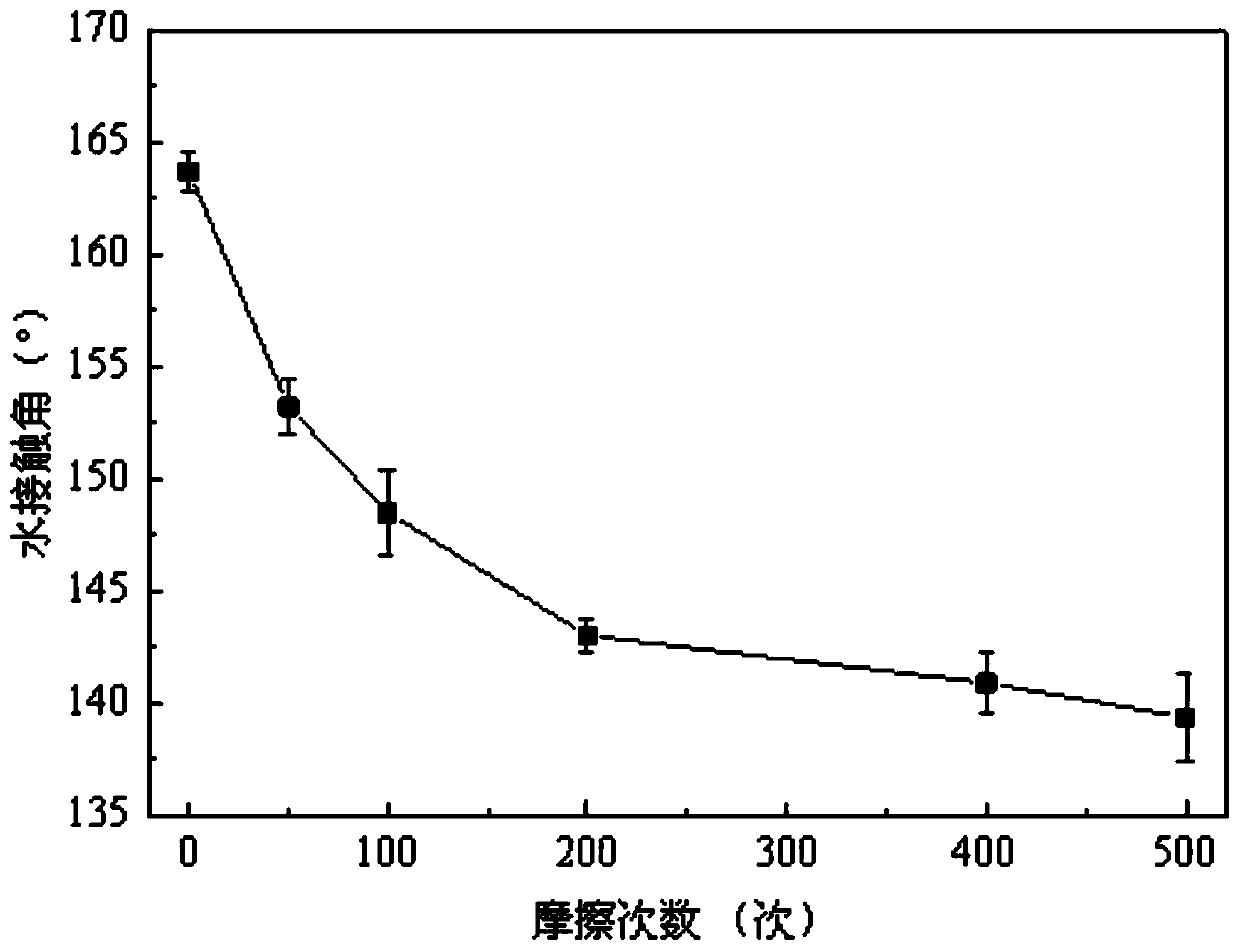

[0031] (3) Place the polyester fabric obtained by drying on the lower pole plate in the parallel plate in the plasma discharge chamber, adjust the distance between the upper and lower pole plates to be 10.16cm, close the plasma discharge chamber, and evacuate to 20mTorr, thro...

Embodiment 2

[0037] A method for preparing superhydrophobic fabrics through plasma treatment of nanoparticle composite coatings:

[0038] (1) Configure 2g / L detergent 209 and anhydrous sodium carbonate solution, the solution pH=8, soak the polyester fabric in the detergent solution with a bath ratio of 50:1, ultrasonically clean it for 40min, and then wash it with deionized water 3-5 times, put it in the oven to dry, take it out and set aside.

[0039] (2) Cut the pretreated polyester fabric into a size of 40mm×50mm, and place it in 5g / L PDMS and 1g / L nano-SiO 2 Particles were immersed in an alcohol solution with a bath ratio of 30:1 for 10 minutes in an ultrasonic cleaner, and dried at 60°C after taking it out.

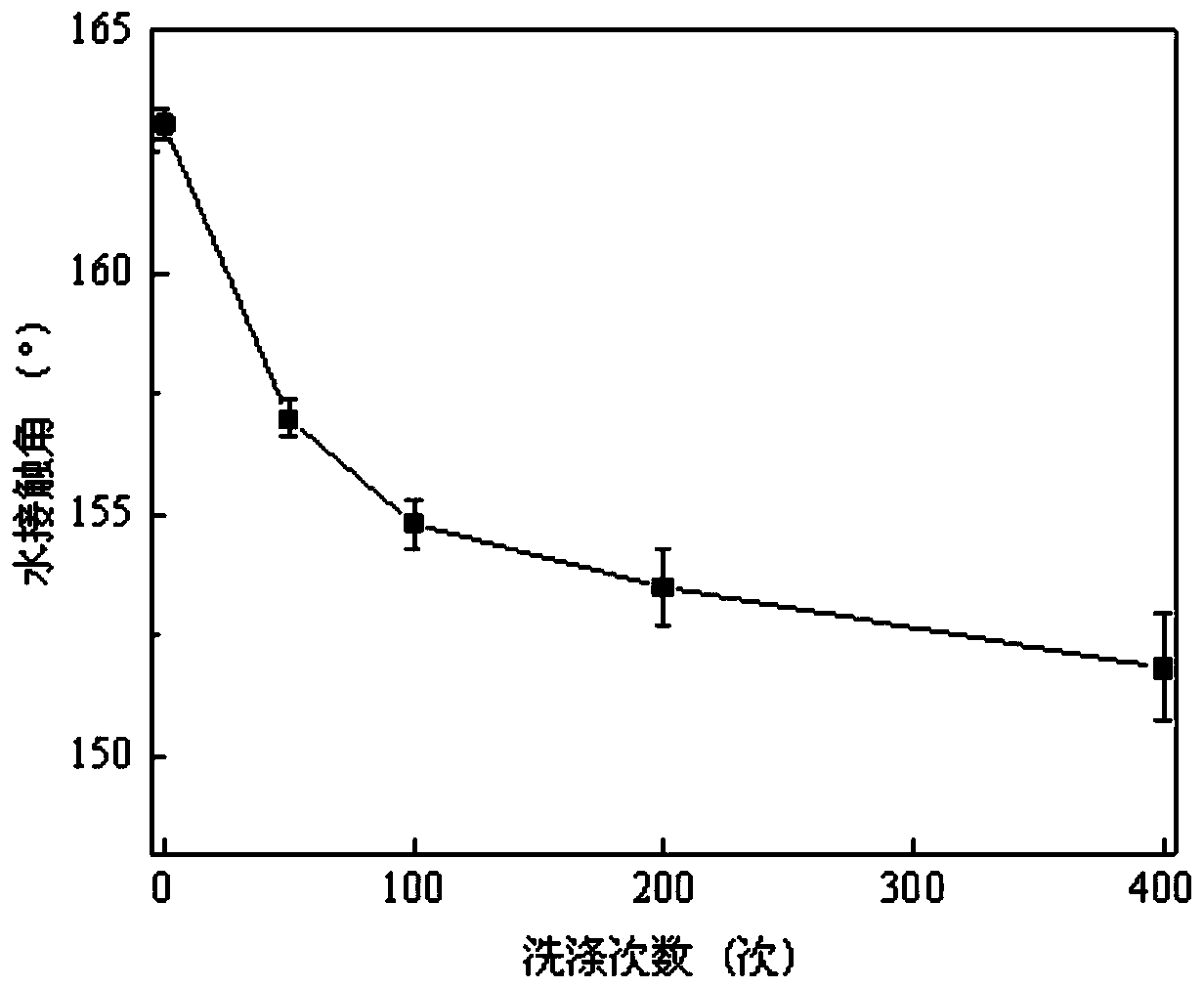

[0040] (3) Place the polyester fabric obtained by drying on the lower pole plate in the parallel plate in the plasma discharge chamber, adjust the distance between the upper and lower pole plates to be 10.16cm, close the plasma discharge chamber, and evacuate to 20mTorr, throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com