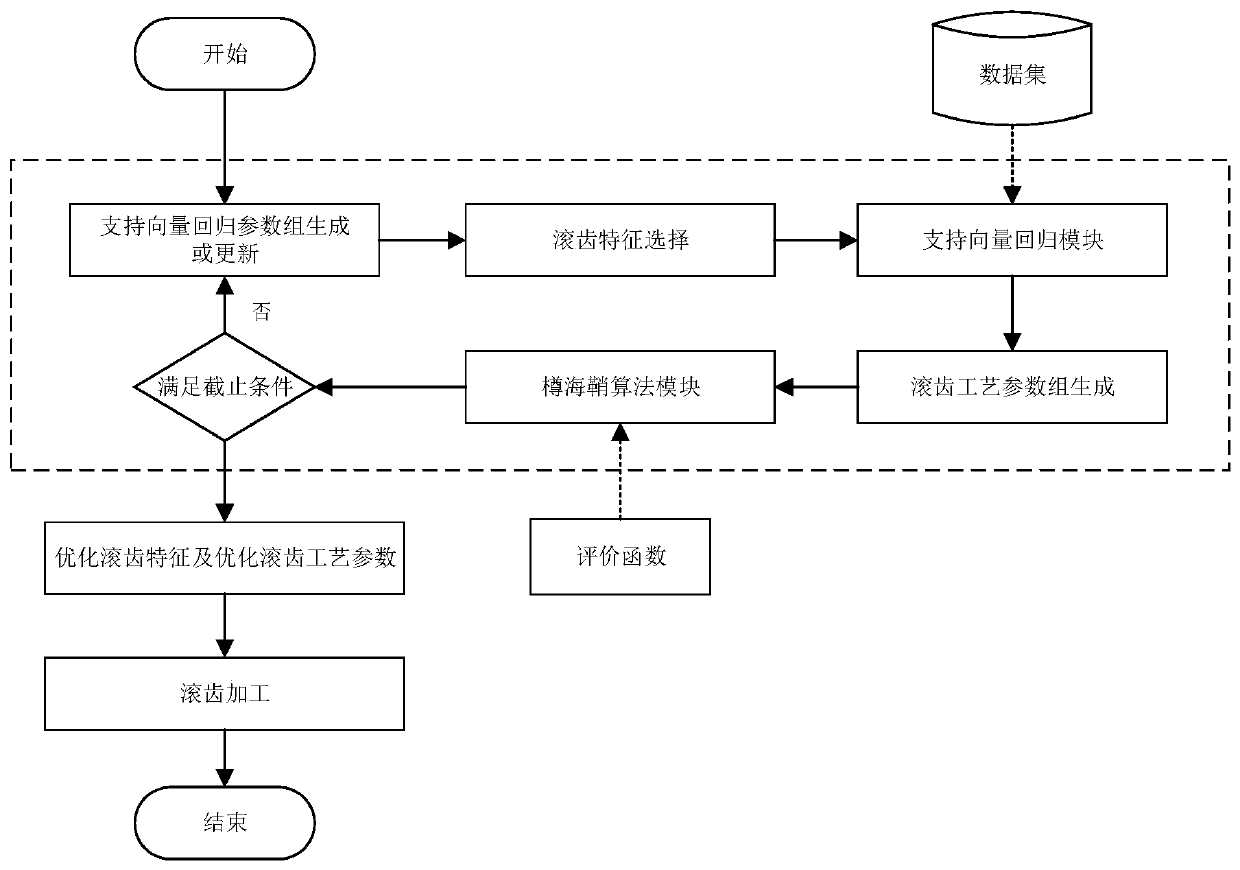

Data-driven and feature-selected gear hobbing processing method

A feature selection and data-driven technology, applied in the field of gear processing, can solve problems such as lack of optimization process parameter library, waste of historical processing cases, and quantitative analysis that has not been achieved, and achieve poor optimization results, eliminate attribute redundancy, and reduce rolling. The effect of the tooth feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

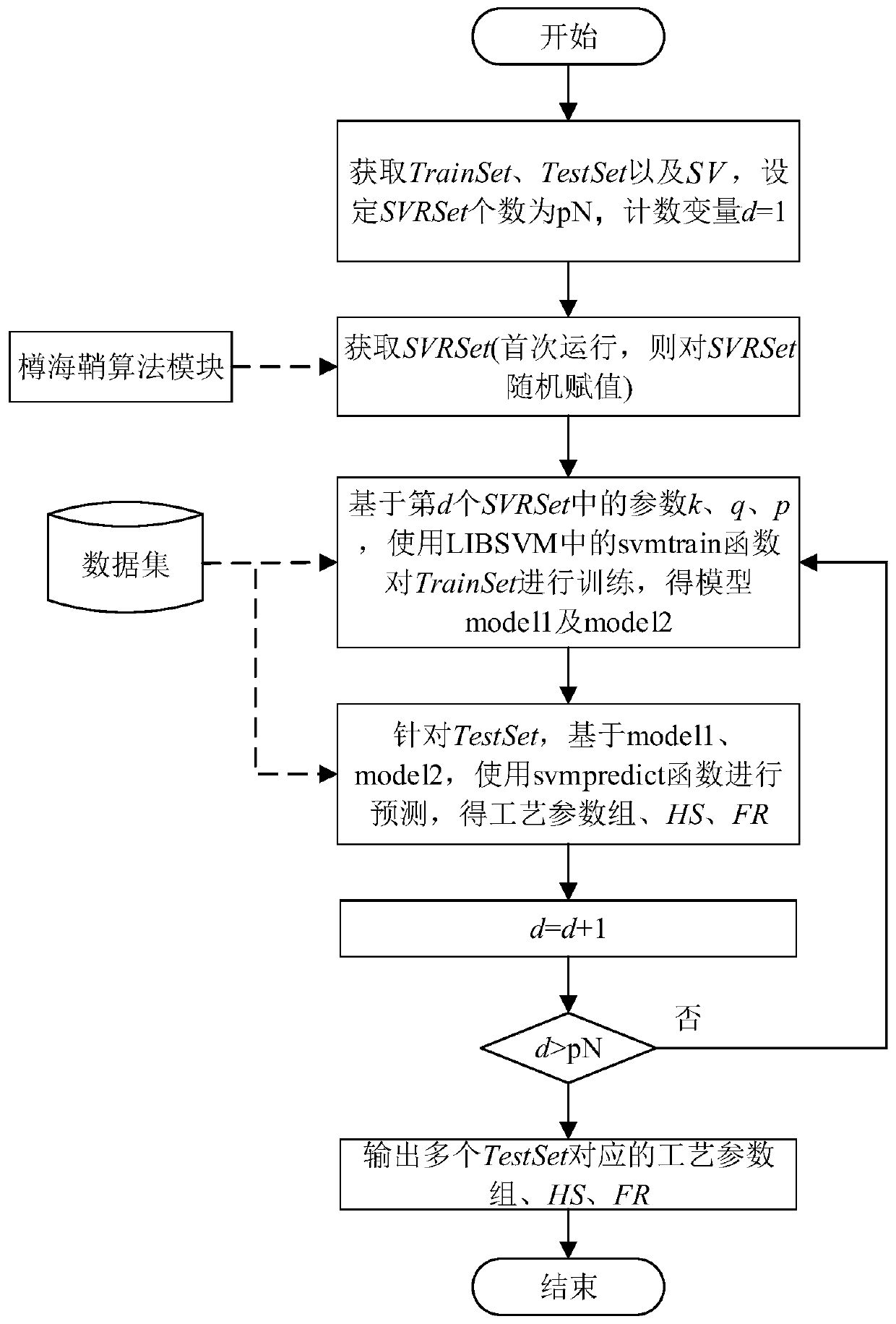

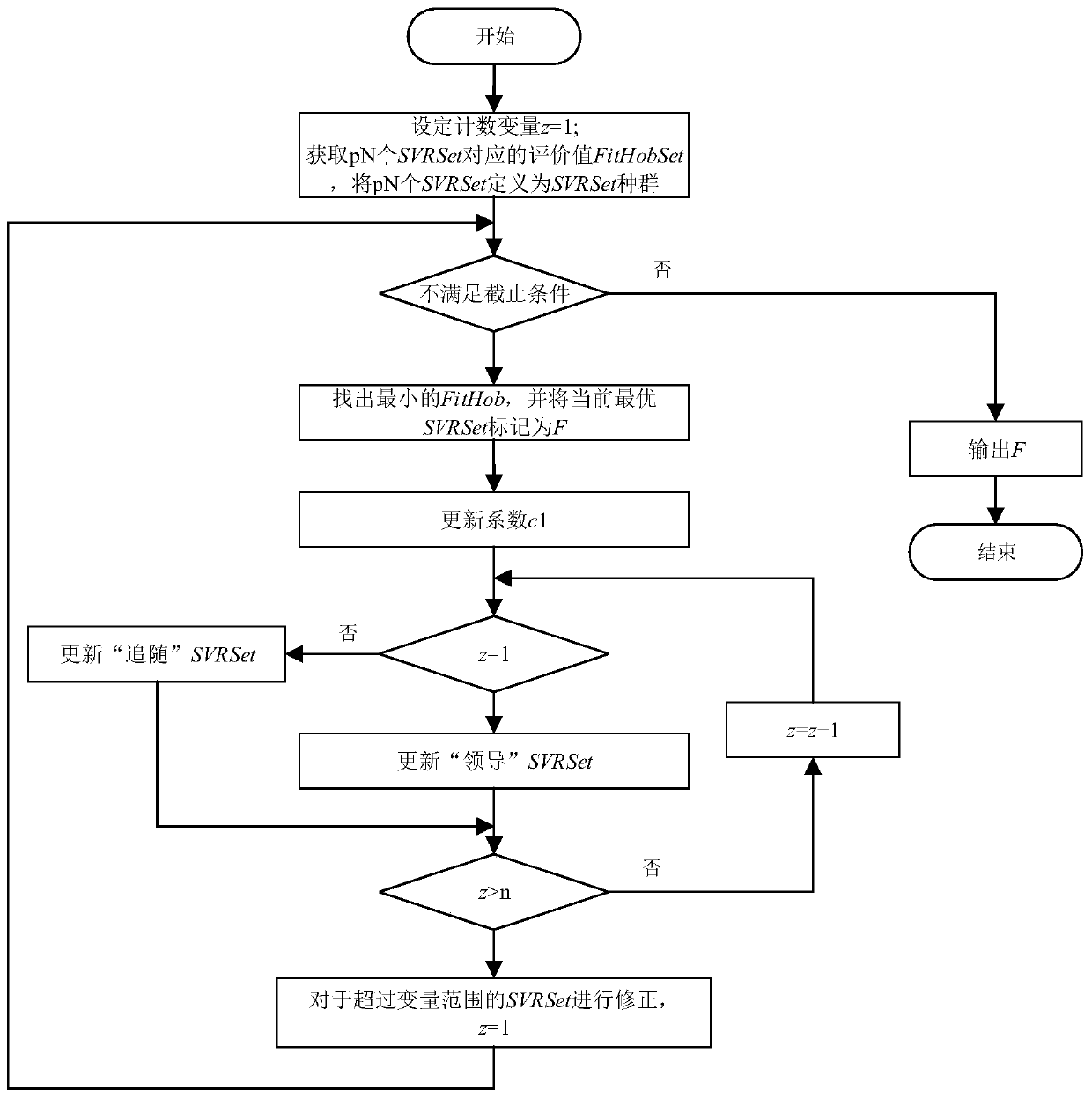

Method used

Image

Examples

Embodiment

[0065] Taking a gear hobbing process in a gear manufacturing enterprise as an example, the machine tool used is a seven-axis four-linkage environmental protection CNC dry cutting gear hobbing machine YS3116CNC7, and the software used is MATLAB. Using the example sample of CNC hobbing process in the gear manufacturing workshop of the gear company, the gear type is cylindrical helical gear, the workpiece material is 40Cr, the Brinell hardness is 200HBW, the machining accuracy is 7 grades, the hobbing type is reverse rolling, and the sample capacity is 18 ,As shown in Table 1.

[0066] Table 1 Hobbing process sample set

[0067]

[0068] Among them: the units of each variable are respectively, f 0 : mm, f 1 : rad, f 3 : rad, f 4 : mm, f 5 : mm, f 6 : mm, f 8 : mm, r 0 : r / min, r 1 : mm / r.

[0069] According to the specific steps of the present invention, during the gear hobbing process, the hobbing process parameters are predicted in the case of data sets, and compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com