Fabrication method of shallow groove isolation structure and chemical mechanical grinding method and system

A technology of chemical machinery and grinding method, which is applied in grinding device, grinding machine tool, control of workpiece feed movement, etc., and can solve the problem that the surface of silicon dioxide is not flat enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] see Figure 5 , the invention provides a kind of chemical mechanical grinding method, described chemical mechanical grinding method comprises the steps:

[0098] 1) Measuring the previous thickness of the target material layer, and determining the first thickness of the target material layer according to the previous thickness of the target material layer and the thickness of the target material layer retained after the first-stage chemical-mechanical polishing. target removal thickness;

[0099] 2) Determine the theoretical grinding rate of the grinding consumable under the actual use time according to the service life and the actual use time of the grinding consumable;

[0100] 3) Dynamically modify the grinding parameters according to the first target removal thickness and the theoretical grinding rate of the grinding consumables under the actual use time, and perform the first-stage chemical-mechanical grinding on the target material layer according to the grinding...

Embodiment 2

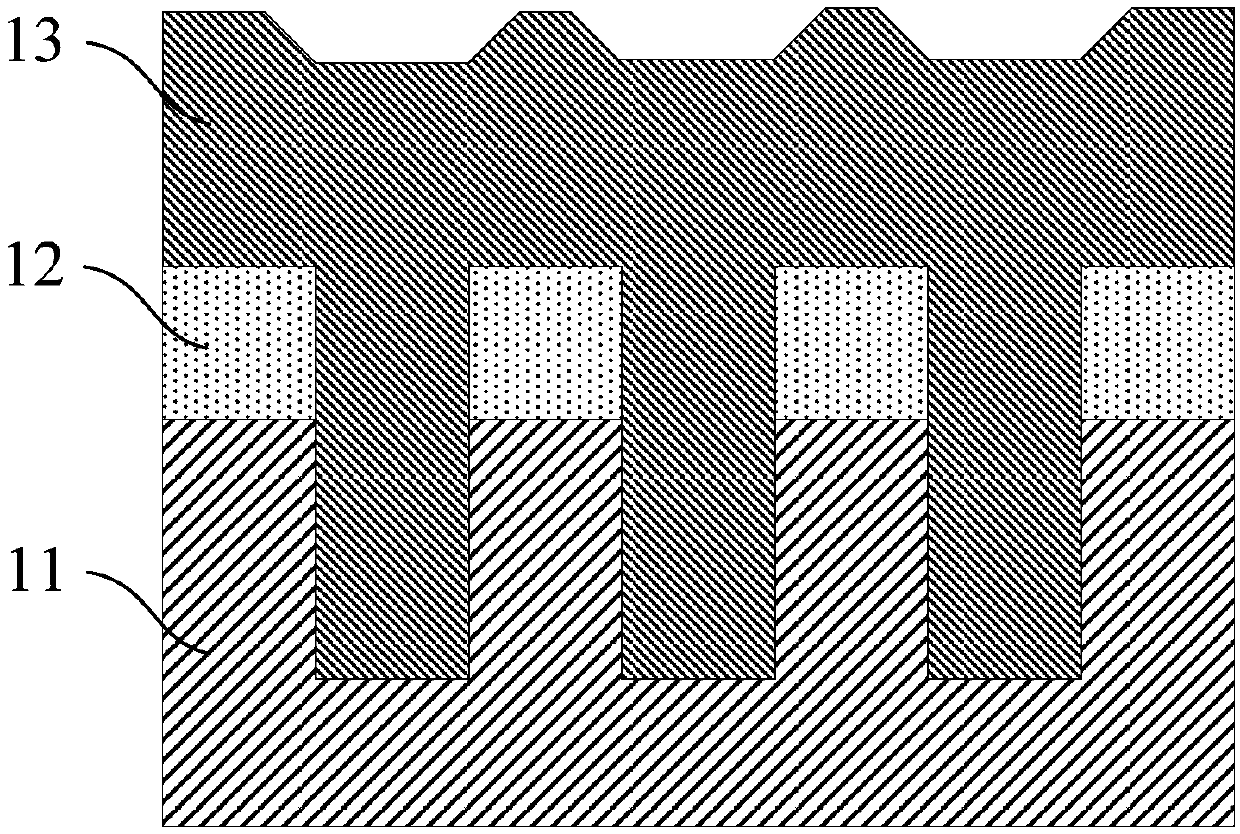

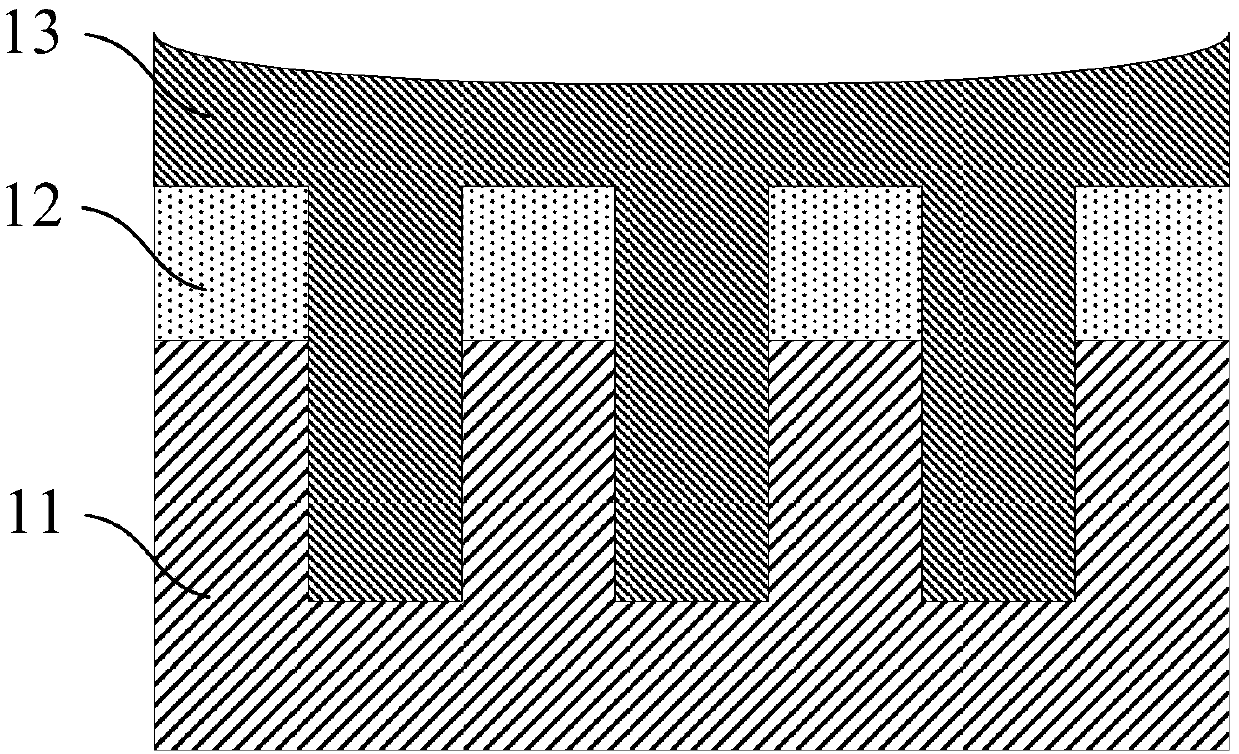

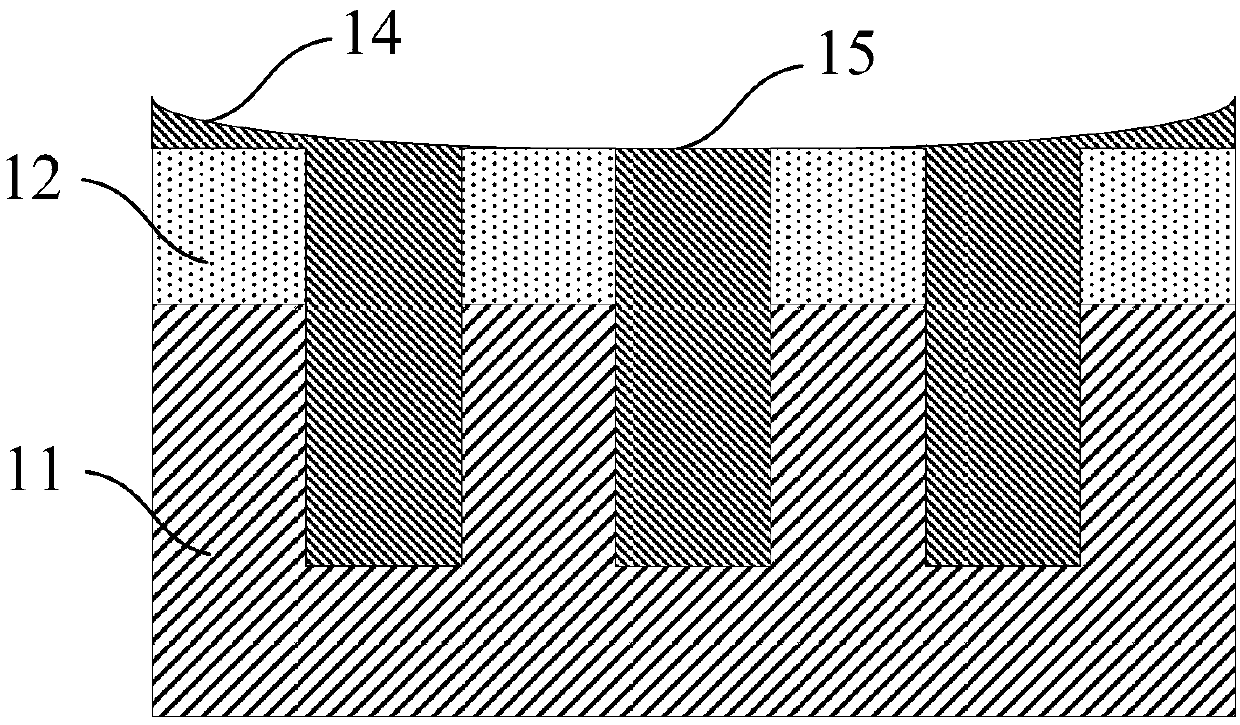

[0137] see Figure 7 ~ Figure 13 , the present invention also provides a method for preparing a shallow trench isolation structure, the method for preparing the shallow trench isolation structure includes the following steps:

[0138] 1) providing a substrate;

[0139] 2) forming a grinding barrier layer on the upper surface of the substrate;

[0140] 3) forming a shallow trench in the substrate, the shallow trench penetrates the barrier layer up and down and extends into the substrate;

[0141] 4) filling the shallow trench with a target material layer, the target material layer filling the shallow trench and covering the upper surface of the polishing stopper layer;

[0142] 5) Using the chemical mechanical polishing method as described in Example 1 to remove the target material layer located on the upper surface of the grinding barrier layer, and the target material layer remaining in the shallow trench constitutes the shallow trench Slot isolation structure.

[0143] I...

Embodiment 3

[0156] see Figure 14, the present invention also provides a chemical mechanical polishing system, which includes: a chemical mechanical polishing device 41 , a first measurement module 411 , a feedforward control module 42 and a processing module 43 .

[0157] The first measurement module 411 is disposed on the chemical mechanical polishing device 41 to measure the previous thickness of the target material layer. This setting can conveniently measure the target material layer of each batch, and feed back the measured value to the chemical mechanical polishing system in real time; the feedforward control module 42 is connected with the first measurement module 411 , used to collect the previous value thickness of the target material layer measured by the first measurement module 411, and feed back the collected data to the processing module 43; the processing module 43 includes at least a first processing unit 433, the The first processing unit 433 is connected to the feedfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com