Brake release tool of motor

A technology for releasing brakes and motors with motors, applied in the field of elevators, can solve problems such as reduced braking force, and achieve the effects of reducing wear, preventing insufficient braking force, and avoiding failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

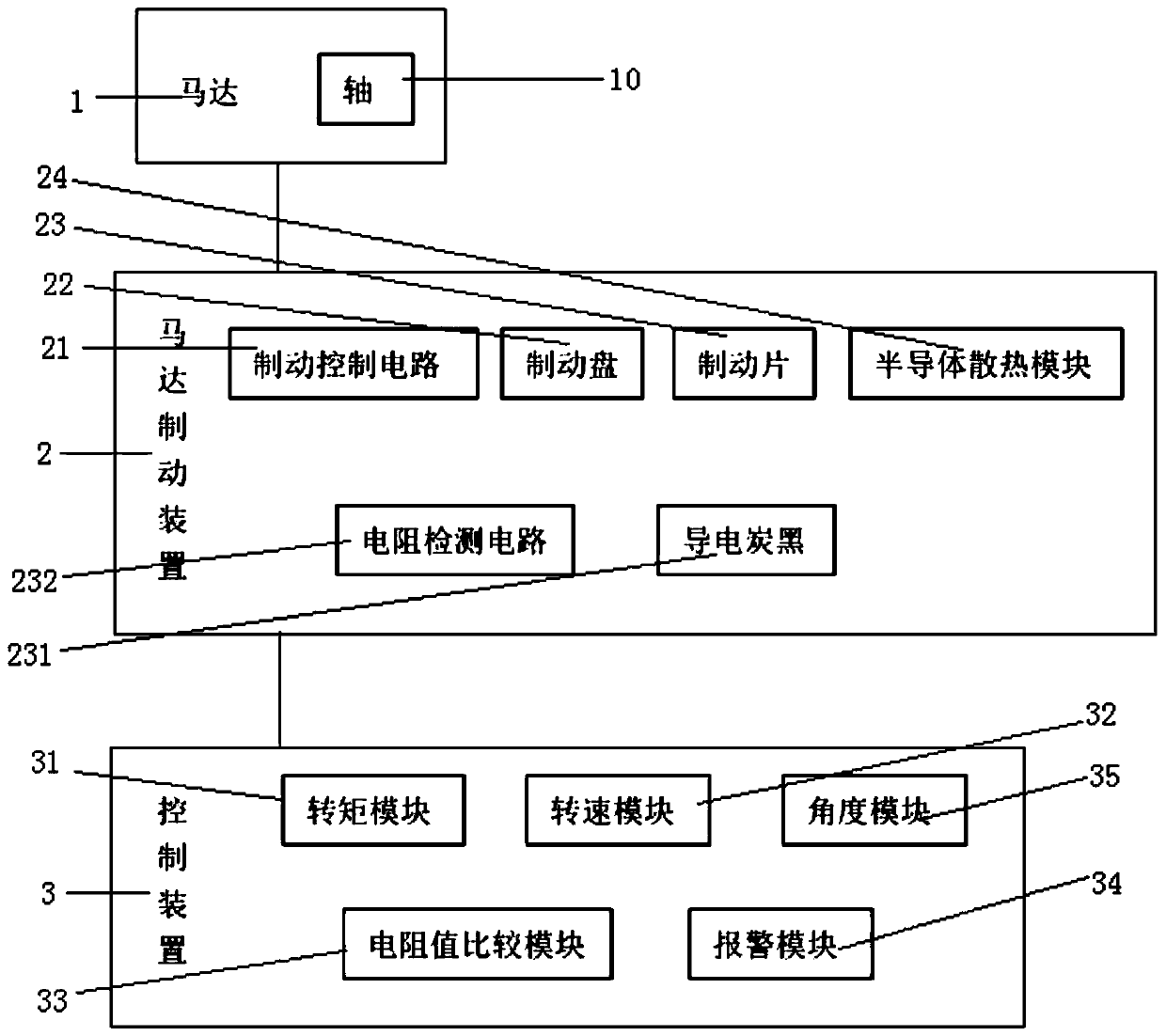

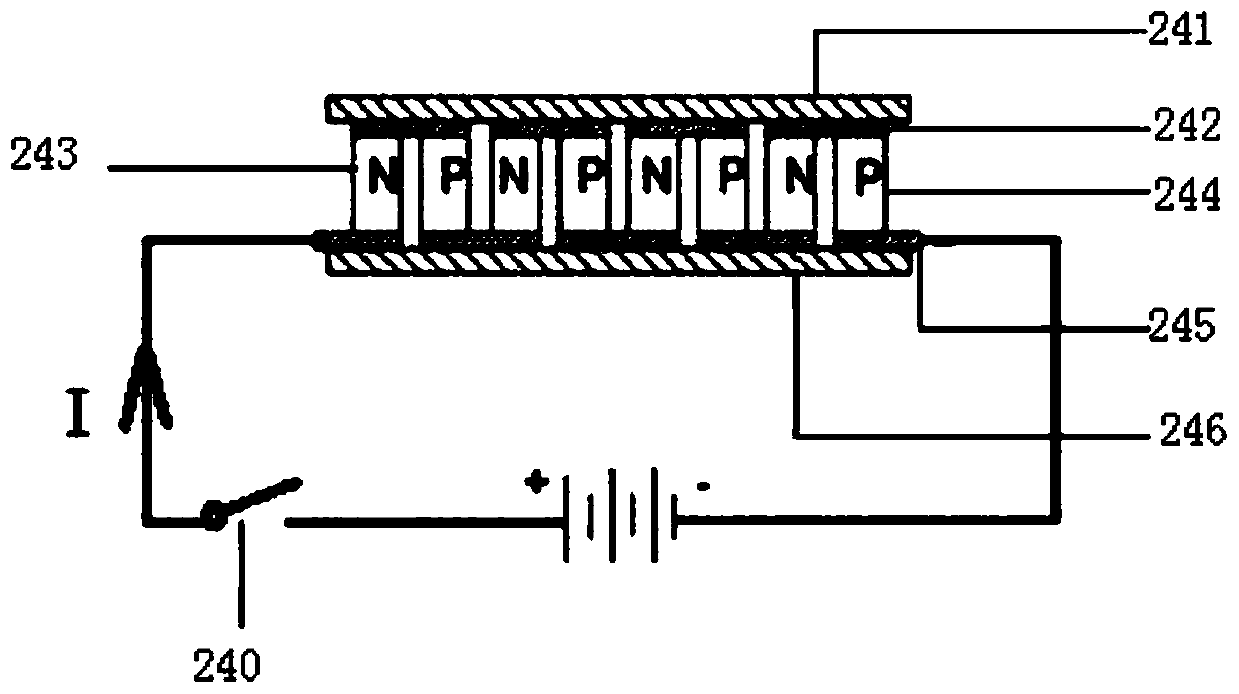

[0027] Please see figure 1 It is a structural schematic diagram of a preferred embodiment of a motor brake release tool of the present invention. A motor brake release tool includes a motor 1, a motor brake device 2, and a control device 3. The motor brake device 2 is arranged on the side of the motor 1. On the shaft 10, the control device 3 is electrically connected to the motor 1 and the motor brake device 2 respectively, and the motor brake device 2 includes a brake control circuit 21, a brake disc 22, a brake pad 23, and a semiconductor cooling module 24 , the brake control circuit 21 is connected to the control device 3, the brake disc 22 is concentrically fixed on the shaft 10 with the motor 1, and the brake control circuit 21 controls the brake pad 23 to lock and release the brake, The outer side of the brake pad 23 is provided with a semiconductor cooling module 24, and the control device 3 includes a torque module 31, a speed module 32, a resistance value comparison m...

Embodiment 2

[0038] This embodiment describes that maintenance personnel run-in the brake disc 22 and the brake pad 23 through the torque module 31 , the speed module 32 , the angle module 35 and the like.

[0039] Through the angle module 35, the rotation angle of the brake disc 22 or the motor 1 relative to the brake pad 23 is determined, and the control device 3 judges the grinding-in position of the brake disc 22 based on the rotation angle, and then controls the torque The module sets a torque smaller than the predetermined torque to lock the brake, so as to perform grinding on the unbroken position.

Embodiment 3

[0041] This embodiment describes the checking of the braking force of the motor braking device 2 by maintenance personnel.

[0042] When there is no one in the elevator car, when the brake pads 23 are engaged and the actual torque received by the torque module 31 is greater than the predetermined torque, it is determined that the braking force is reduced, and the brake needs to be run-in. The predetermined torque is the torque when the motor 1 stops rotating when the motor braking device 2 is in a brake state when the motor braking device 2 is powered off during normal operation. Moment module 31.

[0043] In this application, conductive carbon black is added to form a resistance detection circuit. Through the resistance value comparison module, it can be judged in time whether the motor is running with a brake, which can effectively reduce the wear of the brake pad and reduce the replacement frequency of parts; add conductive carbon black to form a resistance detection circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com