Acrylic glue and manufacturing process of composite acrylic plate using same

A technology of compounding acrylic sheet and acrylic glue, applied in the direction of adhesive type, ester copolymer adhesive, synthetic resin layered products, etc., to achieve the effect of fast curing speed, strong transmission brightness and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

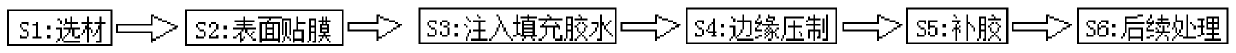

Method used

Image

Examples

Embodiment 1

[0028] A kind of acrylic glue, comprises the raw material of following weight portion:

[0029] 20 parts of PMMA resin, 40 parts of ethyl acetate, 35 parts of dichloromethane, 0.01 part of curing agent, 0.35 parts of light diffusing agent, and 0.1 part of chloroform.

[0030] Further, the PMMA resin has a melt index of 3.0-3.4g / 10min and a density of 1.17-1.21g / cm 3 Methyl hydroxymethacrylate, which has excellent transparency and impact properties, enhances the light transmittance and impact resistance of composite acrylic panels.

[0031] Further, the curing agent is p-hydroxybenzenesulfonic acid, which promotes the curing of the acrylic glue and improves the curing efficiency.

[0032] Further, the light diffusing agent is an acrylic organic light diffusing agent, which can increase the scattering and transmission of light in the transparent glue injection layer, cover the light source and the glare light source, and make the whole resin emit softer, more beautiful and eleg...

Embodiment 2

[0035] 15 parts of PMMA resin, 60 parts of ethyl acetate, 20 parts of dichloromethane, 0.015 parts of curing agent, 0.65 parts of light diffusing agent, and 0.25 parts of chloroform.

[0036] Further, the PMMA resin has a melt index of 3.0-3.4g / 10min and a density of 1.17-1.21g / cm 3 Methyl hydroxymethacrylate, which has excellent transparency and impact properties, enhances the light transmittance and impact resistance of composite acrylic panels.

[0037] Further, the curing agent is p-hydroxybenzenesulfonic acid, which promotes the curing of the acrylic glue and improves the curing efficiency.

[0038] Further, the light diffusing agent is an acrylic organic light diffusing agent, which can increase the scattering and transmission of light in the transparent glue injection layer, cover the light source and the glare light source, and make the whole resin emit softer, more beautiful and elegant light. , to achieve the comfortable effect of light transmission and opacity.

...

Embodiment 3

[0041] 20 parts of PMMA resin, 50 parts of ethyl acetate, 25 parts of dichloromethane, 0.012 parts of curing agent, 0.5 parts of light diffusing agent, and 0.15 parts of chloroform.

[0042] Further, the PMMA resin has a melt index of 3.0-3.4g / 10min and a density of 1.17-1.21g / cm 3 Methyl hydroxymethacrylate, which has excellent transparency and impact properties, enhances the light transmittance and impact resistance of composite acrylic panels.

[0043] Further, the curing agent is p-hydroxybenzenesulfonic acid, which promotes the curing of the acrylic glue and improves the curing efficiency.

[0044] Further, the light diffusing agent is an acrylic organic light diffusing agent, which can increase the scattering and transmission of light in the transparent glue injection layer, cover the light source and the glare light source, and make the whole resin emit softer, more beautiful and elegant light. , to achieve the comfortable effect of light transmission and opacity.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com