Target material doped with metal Na, preparation method of back electrode layer and cigs solar cell

A technology of solar cells and back electrodes, applied in metal material coating process, coating, circuit, etc., to achieve the effect of improving energy conversion efficiency, simple operation, and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

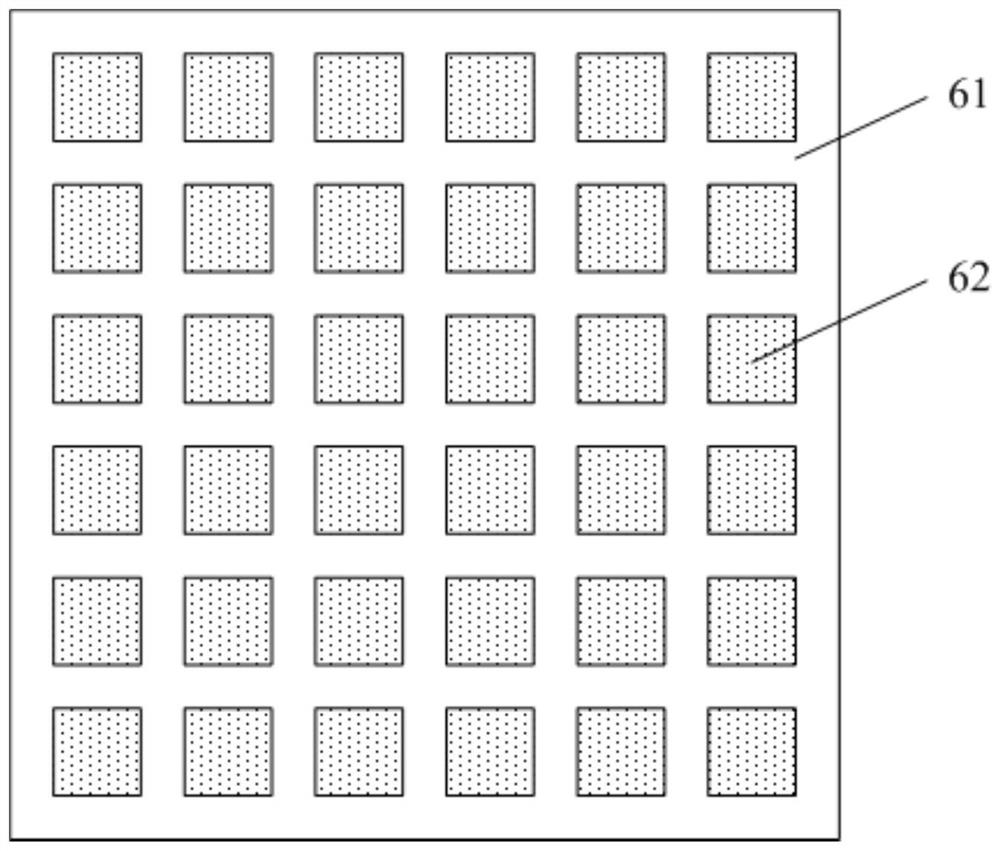

[0046] This embodiment provides a target material doped with metal Na, including a first target material and a second target material, the structure and size of the first target material and the second target material can be the same or different, see Figure 9 to Figure 10 , the first target includes a stacked first Mo layer 9 and a first Na-doped layer 10, the second target includes a stacked second Mo layer 9' and a second Na-doped layer 10', the first Mo layer 9 and the second Mo layer 9' are made of metal Mo, the first Na-doped layer 10 and the second Na-doped layer 10' are made of metal Mo doped with metal Na, and the Na of the first Na-doped layer 10 The doping amount is larger than the Na doping amount of the second Na-doped layer 10'.

[0047] The above-mentioned target material can be used to form a single-layer back electrode layer and a composite back electrode layer of at least two layers. Exemplarily, on the premise of not adjusting the strength of the sputterin...

Embodiment 2

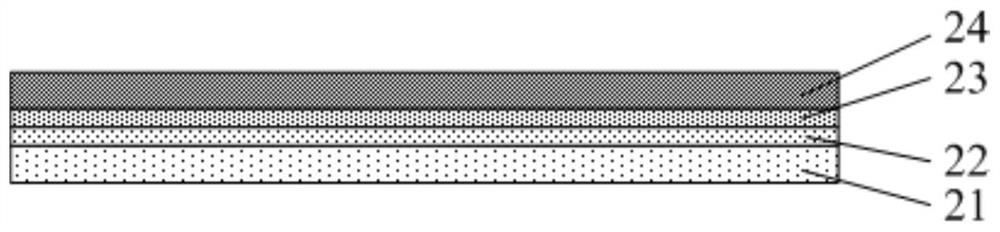

[0051] This embodiment provides a preparation method of the back electrode layer, which is prepared by using the target material doped with metal Na provided in the first embodiment. The preparation method of the electrode sublayer 21, the second electrode sublayer 22, the third electrode sublayer 23 and the fourth electrode sublayer 24 includes the following steps:

[0052] Step 1: placing the first Mo layer 9 and / or the second Mo layer 9' in the film-forming area, and sputtering on the substrate to obtain the first electrode sub-layer 21 of pure metal Mo;

[0053] Step 2: placing the second Na-doped layer 10' in the film-forming region, and sputtering on the first electrode sub-layer 21 to obtain the second electrode sub-layer 22 with the lowest Na doping amount;

[0054] Step 3: placing the first Na-doped layer 10 and the second Na-doped layer 10' in the film-forming region, and sputtering on the second electrode sub-layer 22 to obtain a third electrode sub-layer 23 with a ...

Embodiment 3

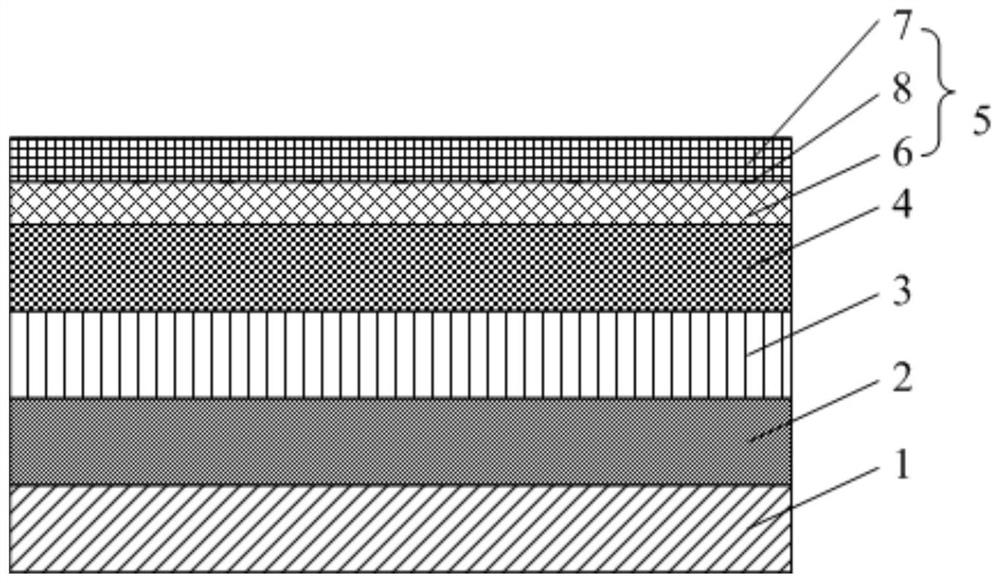

[0058] This embodiment provides a CIGS solar cell doped with metal Na, see Figure 1 to Figure 7 , including a substrate 1 and a back electrode layer 2, a CIGS layer 3, a buffer layer 4 and a transparent surface electrode layer 5 sequentially stacked on the substrate 1, wherein the back electrode layer 2 is doped with metal Na, from the substrate 1 to the transparent surface electrode In the direction of layer 5, the doping amount of Na in the back electrode layer 2 increases gradually. That is to say, the back electrode layer 2 can have a structure of at least two layers. The Na doping amount of the layer is higher than the Na doping amount of the electrode sublayer remote from the transparent surface electrode layer 5 . Specifically, the Na doping amount in the multilayer electrode sublayers can be increased in a gradient manner in an equal difference and equal ratio.

[0059] It should be noted that in practical applications, although the thickness of the back electrode la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com