Building template release agent and building template thereof

A technology of building formwork and release agent, which is used in construction, building structure, and on-site preparation of building components, etc. Acid hydrolysis and other problems occur to achieve the effect of dense release layer, strong adhesion, good isolation effect and lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

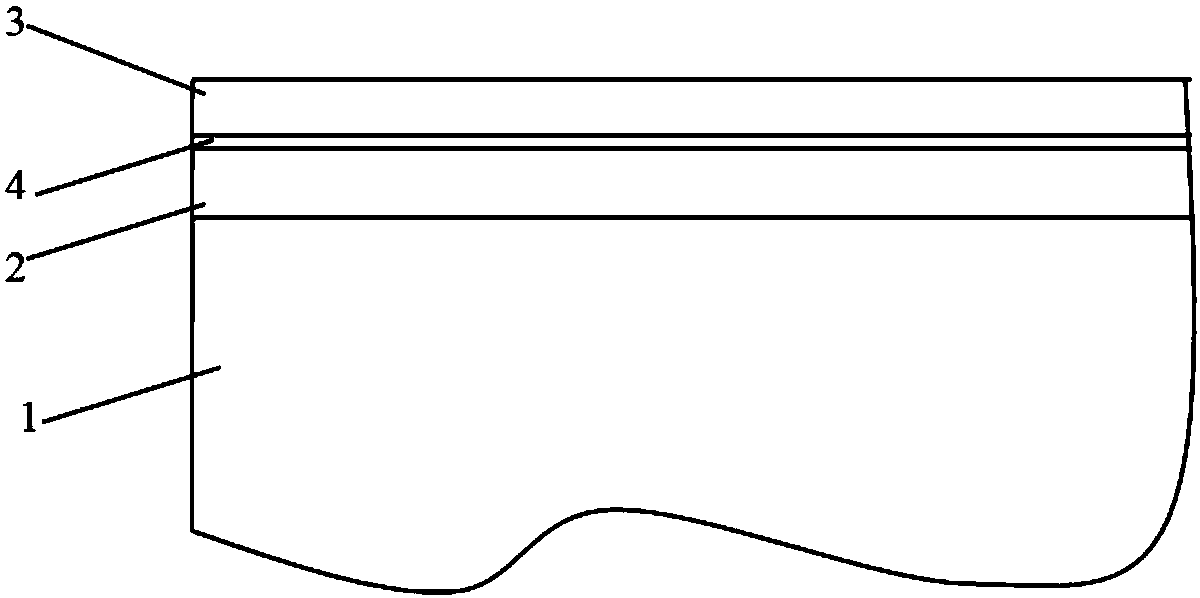

Image

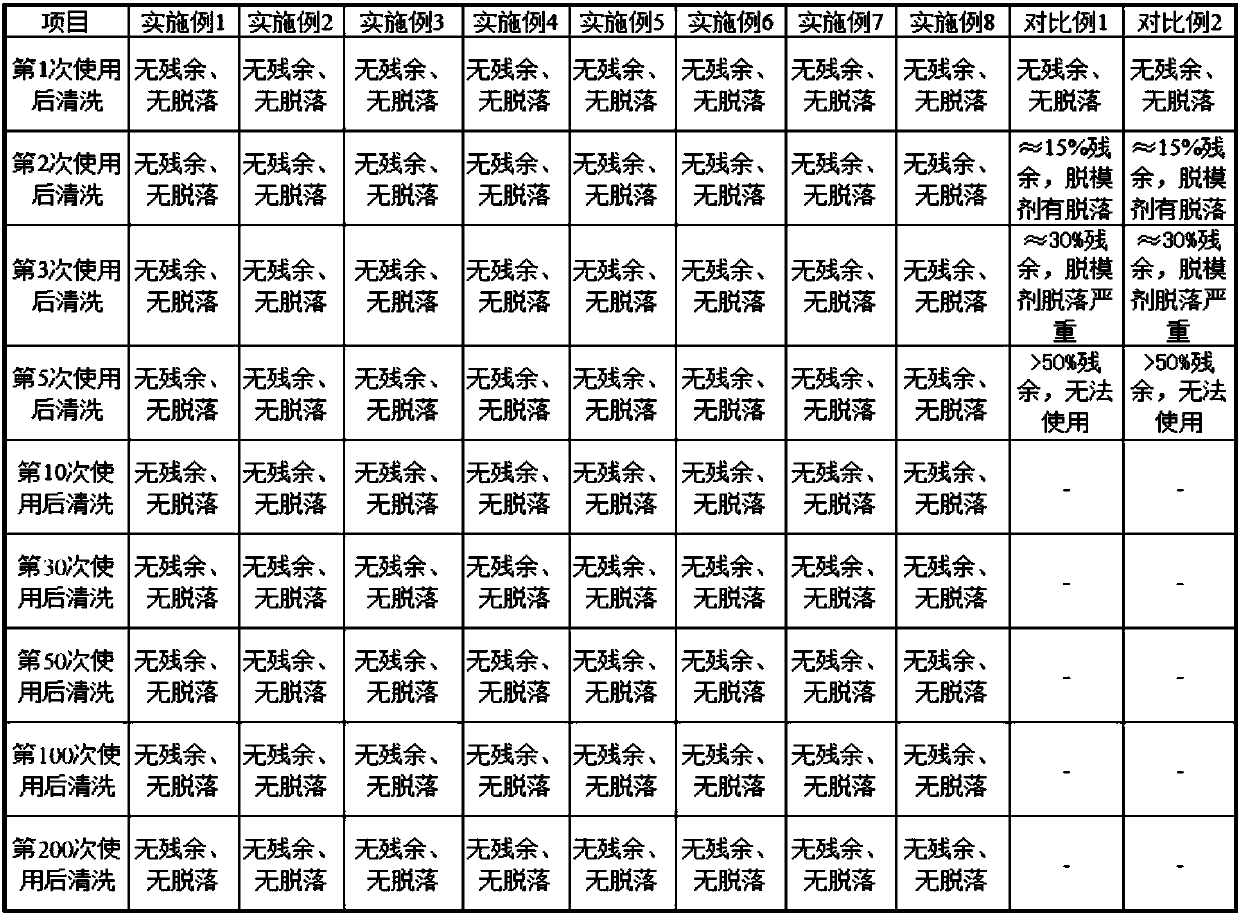

Examples

Embodiment 1

[0022] A building formwork release agent, comprising A component and B component, by weight percentage, A component comprises 40% rosin, 10% styrene-butadiene copolymer, 25% paint spirit and 25% ethyl acetate, component B consists of 90% cyanoacrylate and 10% hydroxyethyl cellulose.

[0023] Spray component A on the surface of the wooden formwork, dry at room temperature for 2 hours to form a primer layer, spray component B on the surface of the primer layer, and obtain a cured and dried release layer after 1 minute.

Embodiment 2

[0025] A building formwork release agent, comprising A component and B component, by weight percentage, A component comprises 40% rosin, 10% styrene-butadiene copolymer, 25% paint spirit and 25% ethyl acetate, component B consists of 90% cyanoacrylate and 10% hydroxyethyl cellulose.

[0026] Spray component A on the surface of the steel formwork, dry at room temperature for 2 hours to form a primer layer, spray component B on the surface of the primer layer, and obtain a cured and dried release layer after 1 minute.

Embodiment 3

[0028] A building formwork release agent, comprising A component and B component, by weight percentage, A component comprises 40% rosin, 10% styrene-butadiene copolymer, 25% paint spirit and 25% ethyl acetate, component B consists of 90% cyanoacrylate and 10% hydroxyethyl cellulose.

[0029] Spray component A on the surface of the aluminum template, dry at room temperature for 2 hours to form a primer layer, spray component B on the surface of the primer layer, and obtain a cured and dried release layer after 1 minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com