Phase mask plate structure for simultaneous writing of multiple fiber gratings

A phase mask, simultaneous timing technology, applied in the directions of cladding fiber, optical waveguide light guide, light guide, etc., can solve the problems of laser ultraviolet beam energy waste, high fiber grating manufacturing cost, low production efficiency, etc., to avoid laser The effect of serious waste of beam energy, reduction of additional fiber positioning tooling, and improvement of energy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

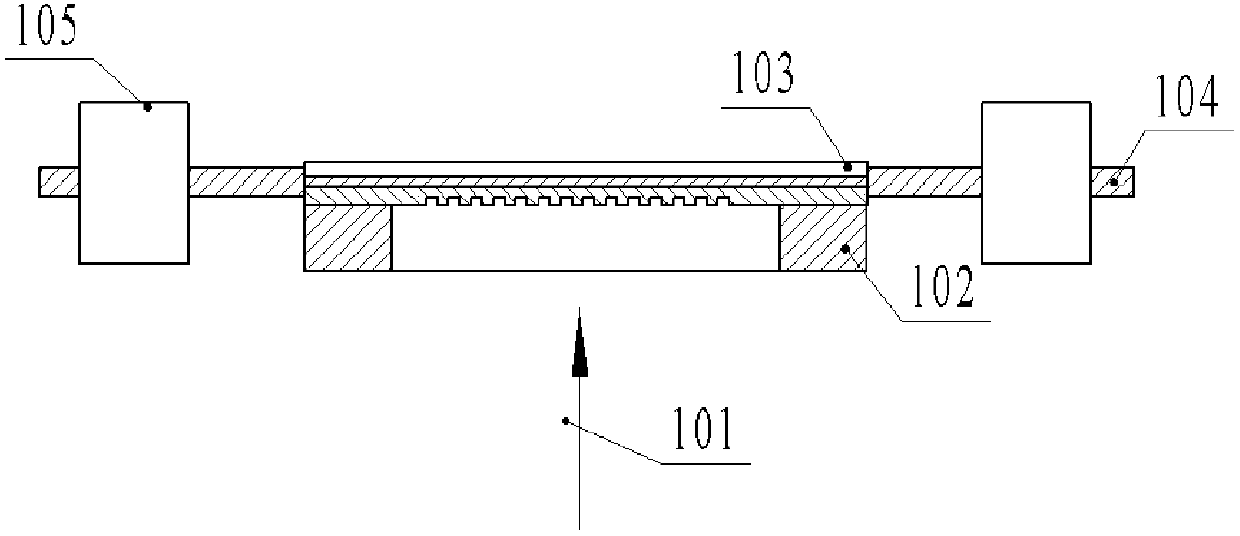

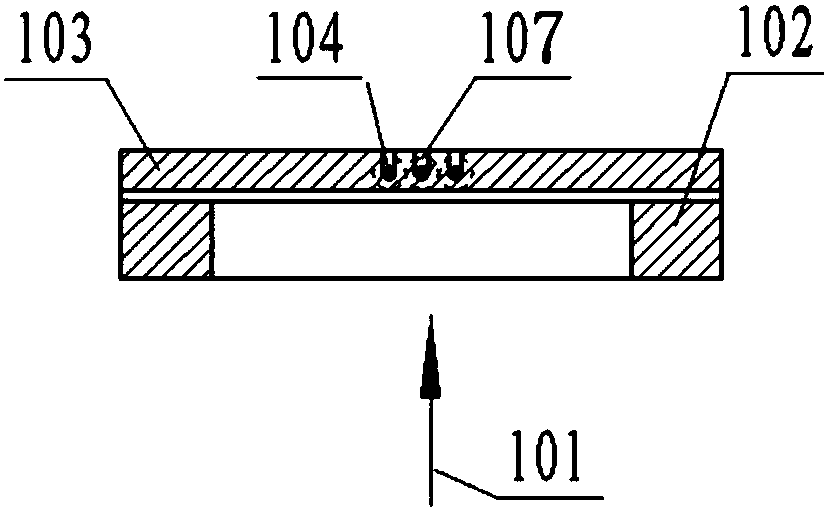

[0034] see figure 1 , 2 , the implementation steps of the present invention: several (this embodiment takes three as an example) bare optical fibers 104 are placed horizontally in the U-shaped positioning grooves on the non-grating side of the phase mask 103 in sequence, and the three optical fibers are positioned and positioned on the current phase mask. 103, and according to the U-shaped positioning groove structure processed on the non-grating side of the phase mask 103, the three optical fibers have the following arrangement characteristics: (1), the bare optical fiber 104 is positioned on the non-grating side of the phase mask 103 After the groove, the major optical fibers are evenly spaced; (2), the center distance between the bare optical fibers 104 is L, L≥D, and D is the diameter of the optical fiber in the coating area; (3), the optical fiber is located in the positioning groove Finally, the bare optical fiber 104 falls on the bottom of the positioning groove, and t...

Embodiment 2

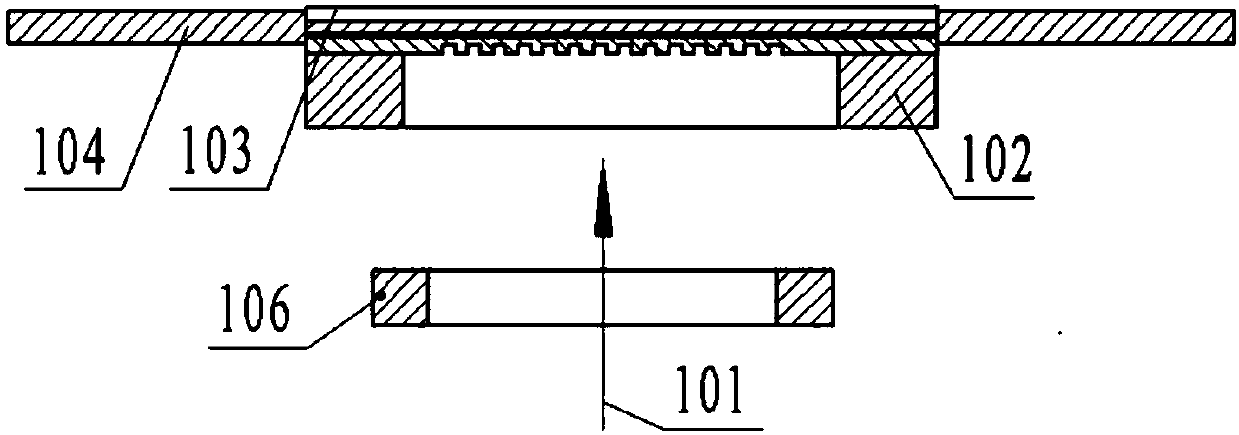

[0036] Same as implementation case 1, for the difference, see image 3 , 4 : (1), the structure of the positioning groove on the non-grating side of the phase mask 103 is different, the U-shaped positioning groove of the optical fiber on the non-grating side of the phase mask 103 is changed to a V-shaped positioning groove, and the structure of the V-shaped positioning groove on the non-grating side of the phase mask 103 is obtained , multiple optical fibers fall on the bottom of the V-shaped groove for positioning; (2), the bottom of the V-shaped positioning groove cannot realize the function of converging the laser beam. Therefore, in this embodiment, a phase mirror 106 can be added in front of the phase mask 103 to realize the beam Convergence function, this kind of multi-fiber phase mask 103 structure, after positioning, the distance between the bare optical fibers 104 depends on the thickness of the phase mask 103 and the size of the top angle of the V-shaped groove, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com