Special bronze red ink powder for official document printing and preparation method thereof

A technology for red head document and toner, applied in the field of golden red toner and its preparation, can solve the problems of waste, waste of printing plates and printed documents, etc., and achieve the effects of stable performance, good compatibility, and improved low-temperature fixing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation process of electronegative golden light red toner comprises the steps among the present invention:

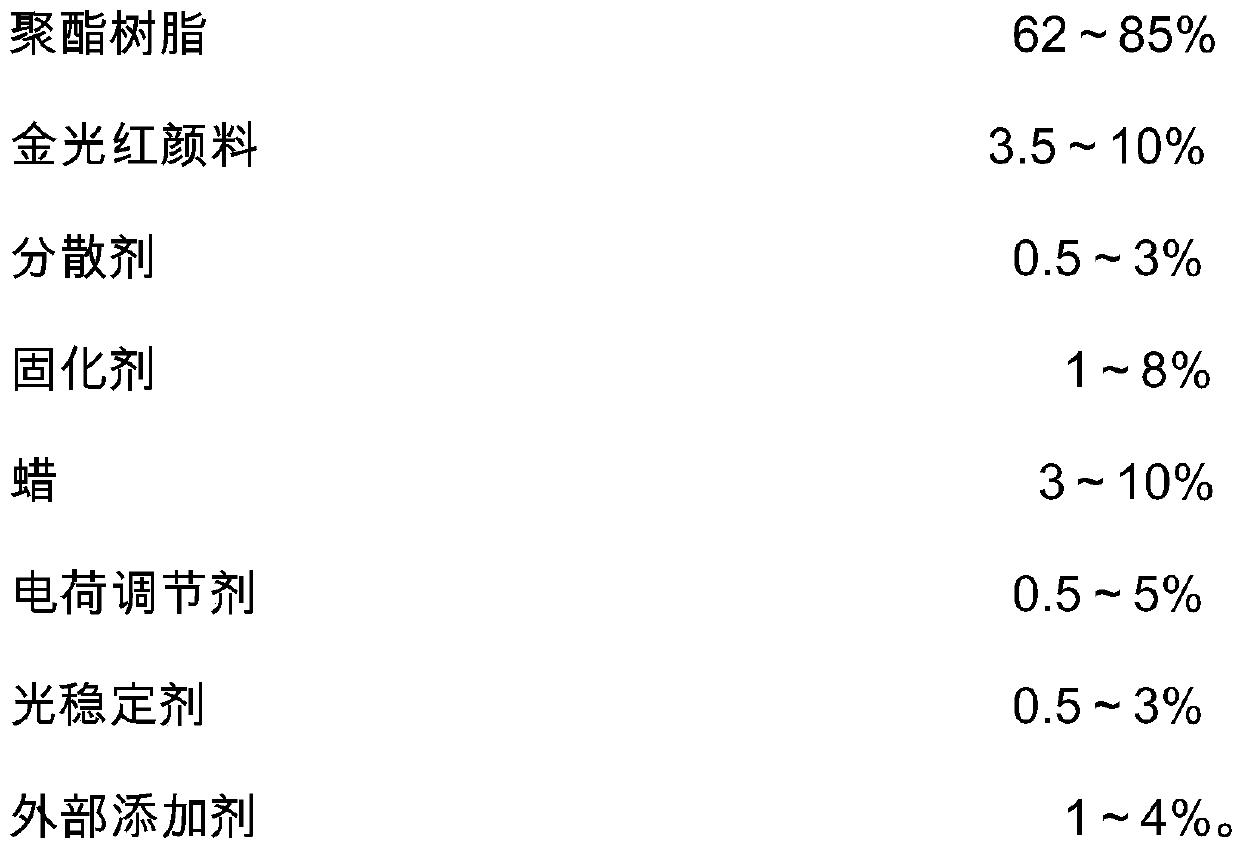

[0049] 1. According to the ratio of formula 1 in Table 1, mix the polyester resin, golden red pigment, dispersant, curing agent, wax, charge regulator, and light stabilizer evenly in a high-speed mixer; then use a mixer to melt and mix , the mixing temperature is 110°C, cooled and pressed to form flakes, and the flakes are then mechanically crushed to coarse particles with a particle size of 1-2 mm;

[0050] 2. The mechanically crushed flakes enter the jet mill (pressure 0.5MPa, frequency 20Hz), superfine crushing and grading system (speed 10000rpm, air volume 20Nm 3 / h), to obtain a graded product with a volume D50 of 10-11 μm;

[0051] 3. After mixing the graded product with the external additives in the formula, stir for 10 minutes at a stirring speed of 20 m / s, and pass through a 150-mesh sieve to obtain golden red toner.

Embodiment 2

[0053] The preparation process of electronegative golden light red toner comprises the steps among the present invention:

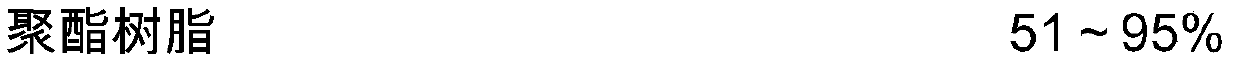

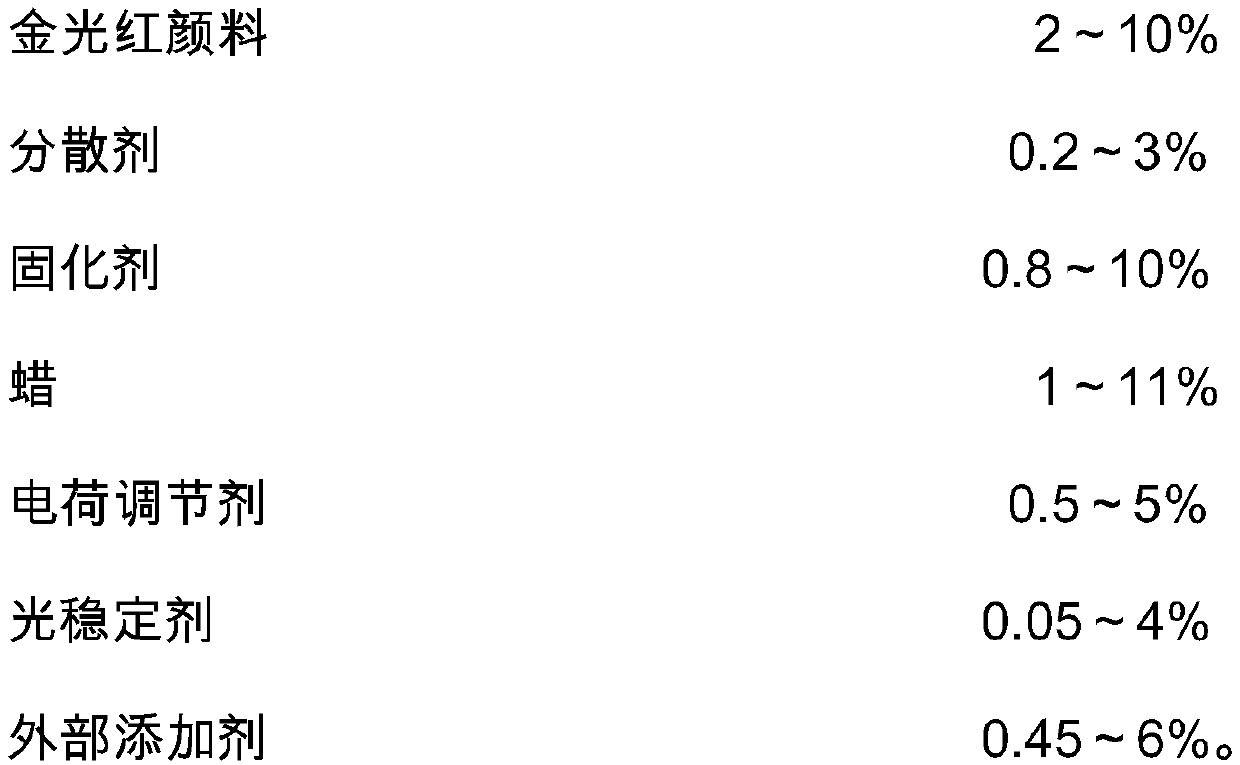

[0054] 1. Mix polyester resin, golden red pigment or mixed pigment, and dispersant according to the ratio of formula 2 in Table 1, and mix them evenly in a high-speed mixer. The mixing time is 5 minutes, and the speed is 1000 rpm. The kneading machine is melted and mixed, the mixing temperature is 115°C, the extrusion rate is 5kg / h, cooled and pressed to form flakes, and the flakes are mechanically crushed to coarse particles with a particle size of 1-2 mm, thereby obtaining pigments Predispersion A;

[0055] 2. According to the ratio of formula 2 in Table 1, mix the pigment predispersion A, wax, charge regulator, light stabilizer, and curing agent evenly to form mixture B, and mix mixture B evenly in a high-speed mixer; then use Melting and mixing in a kneading machine, the mixing temperature is 100°C, the extrusion rate is 4kg / h, cooled and pressed to ...

Embodiment 3

[0059] The preparation process of electronegative golden light red toner comprises the steps among the present invention:

[0060] 1. Mix polyester resin, golden red pigment or mixed pigment, and fatty alcohol according to the ratio of formula 3 in Table 1, and mix them evenly in a high-speed mixer. Melt and mix the mixed materials through a mixer, and mix them. The refining temperature is 120°C, the extrusion rate is 7kg / h, cooled and pressed to form flakes, and the flakes are mechanically crushed to coarse particles with a particle size of 1-2mm, thereby obtaining pigment predispersion A;

[0061] 2. According to the ratio of formula 3 in Table 1, mix the pigment predispersion A, wax, charge regulator, light stabilizer, and curing agent evenly to form mixture B, and mix mixture B evenly in a high-speed mixer; then use The kneading machine is melted and mixed, the kneading temperature is 90°C, cooled and pressed into tablets to form flakes, and the flakes are then mechanicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com